Organic seedling raising matrix and production method thereof

A kind of technology for raising seedling matrix and production method, which is applied in the field of plant seedling raising matrix material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

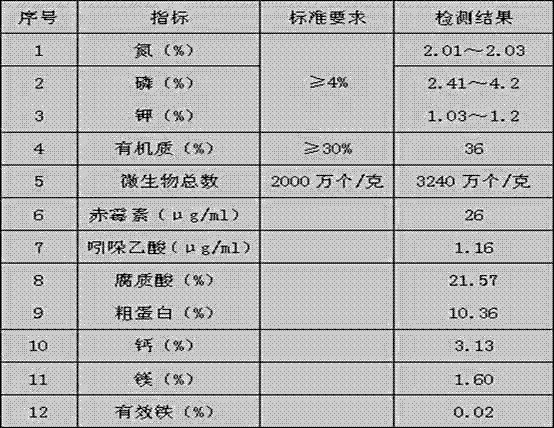

Image

Examples

Embodiment 1

[0023] Component A is a mixture of earthworm metabolites, locust metabolites and Tenebrio molitor metabolites, with 6 parts by volume, including 2 parts of earthworm metabolites, 2 parts of locust metabolites, 2 parts of Tenebrio molitor metabolites, component A The moisture content is 20%; the component B is mushroom slag, the volume part is 4 parts, and the moisture content of the component B is 20%.

[0024] The production steps are:

[0025] (1) Collect component A and component B, and test their moisture content respectively, the moisture content of component A is 20%, and the moisture content of component B is 20%;

[0026] (2) sieve component A and component B obtained in step (1) respectively into raw materials with a particle size of 3-5 mm for later use;

[0027] (3) stirring and mixing the raw materials obtained in step (3);

[0028] (4) drying or air-drying the mixture obtained in step (3), detecting the moisture content of the mixture, and obtaining the organic ...

Embodiment 2

[0031] Component A is a mixture of earthworm metabolites and locust metabolites, with 6 parts by volume, including 3 parts of earthworm metabolites and 3 parts of locust metabolites. The moisture content of component A is 30%; component B is mushroom slag , the number of parts by volume is 4 parts, and the water content of component B is 30%.

[0032] The production steps are:

[0033] (1) Collect component A and component B, and test their moisture content respectively, the moisture content of component A is 30%, and the moisture content of component B is 30%;

[0034] (2) sieve component A and component B obtained in step (1) respectively into raw materials with a particle size of 3-5 mm for later use;

[0035] (3) stirring and mixing the raw materials obtained in step (3);

[0036] (4) drying or air-drying the mixture obtained in step (3), detecting the moisture content of the mixture, and obtaining the organic seedling-growing substrate with a moisture content of 30%;

...

Embodiment 3

[0039] Component A is a mixture of locust metabolites and Tenebrio molitor metabolites, with 6 parts by volume, wherein 3 parts of locust metabolites and 3 parts of Tenebrio molitor metabolites. The water content of component A is 20%; component B is Mushroom slag, the number of parts by volume is 4 parts, and the moisture content of component B is 30%.

[0040] The production steps are:

[0041] (1) Collect component A and component B, and test their moisture content respectively, the moisture content of component A is 20%, and the moisture content of component B is 30%;

[0042] (2) sieve component A and component B obtained in step (1) respectively into raw materials with a particle size of 3-5 mm for later use;

[0043] (3) stirring and mixing the raw materials obtained in step (3);

[0044] (4) drying or air-drying the mixture obtained in step (3), detecting the moisture content of the mixture, and obtaining the organic seedling-growing substrate with a moisture content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com