Production method of superthick steel plate by using continuous casting billet in condition of small compression ratio

A technology of extra-thick steel plate and compression ratio, which is applied in the production process of high-toughness and anti-lamellar tear-resistant extra-thick plate, can solve the problems of small thickness of steel plate and increased cost of steel plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

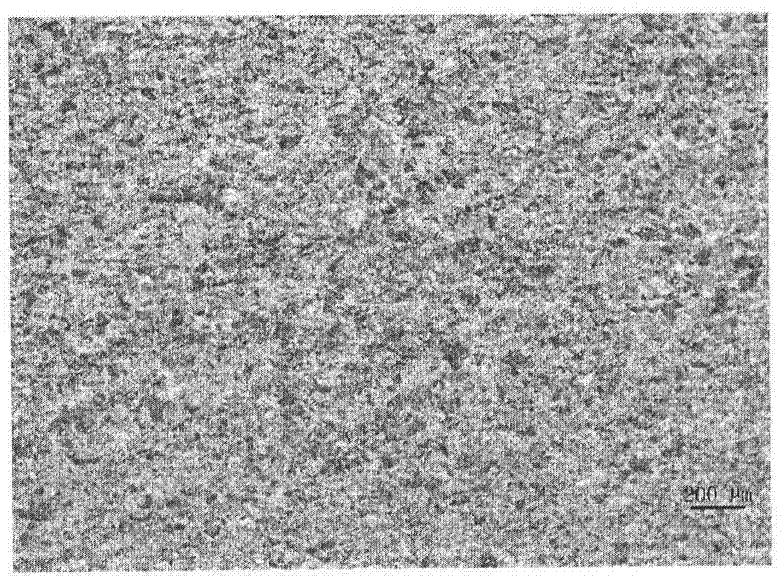

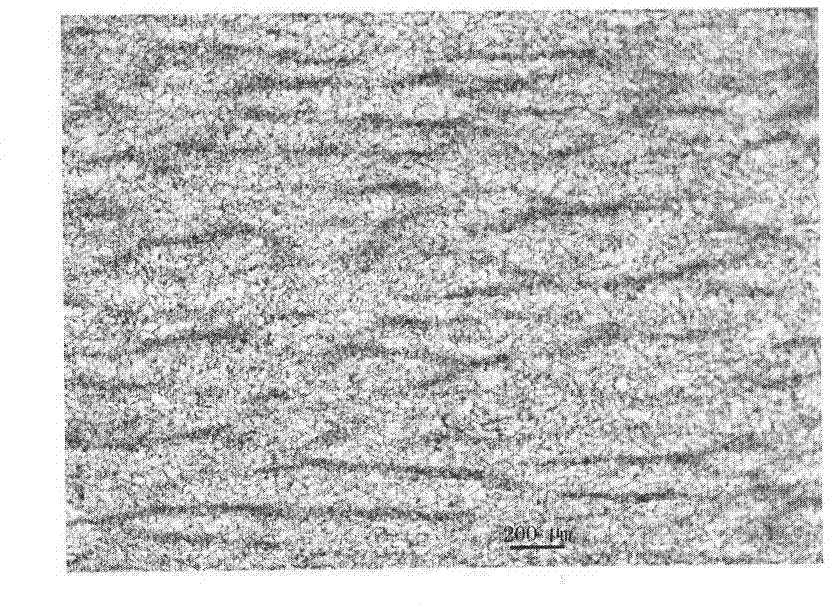

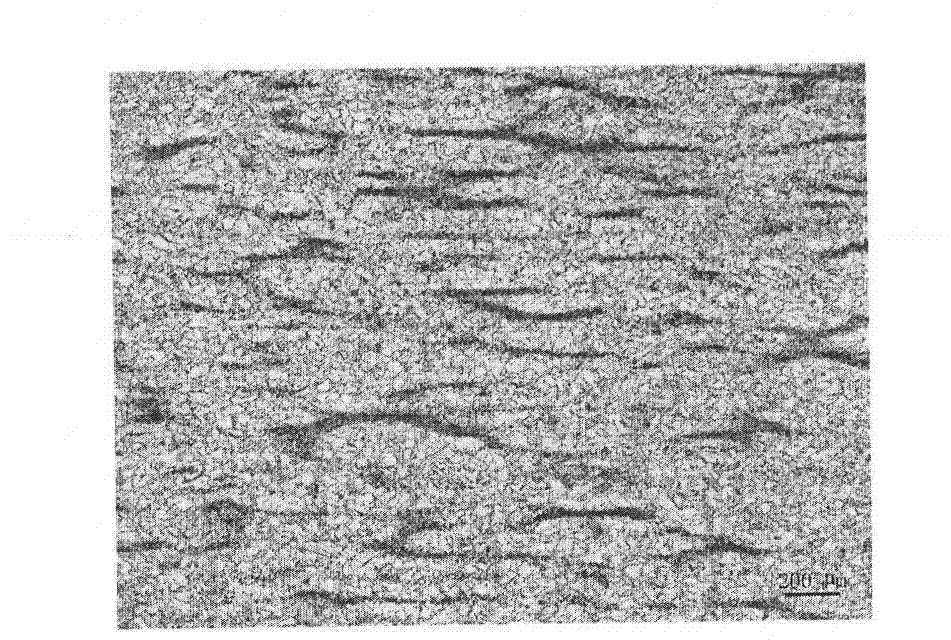

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0019] The object of the present invention is to provide a method for producing extra-thick steel plates with high toughness and lamellar tear resistance. The steel type has relatively low cost, simple process and easy operation, and is very suitable for continuous large-scale production.

[0020] The main chemical composition of the smelted steel plate produced according to the method of the present invention is (calculated by wt%): C≤0.18%, Si≤0.50%, Mn≤1.70%, Nb≤0.07%, Ti≤0.020%, Als≥0.015 %, P≤0.025%, S≤0.005%, and the rest are Fe and unavoidable impurities.

[0021] The method for producing extra-heavy steel plates using continuous casting slabs according to the present invention includes:

[0022] (1) Smelting process: using molten iron, scrap steel, and ferroalloy as the main raw materials, using molten iron pretreatment, top-bottom combined blowing co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com