Production method for insect prevention and removal fabric

A production method and fabric technology, which are applied in the directions of single-component polyolefin rayon filament, single-component polyester rayon filament, fiber chemical characteristics, etc., can solve the problem of no longer having the effect of removing insects, and achieve the effect of removing insects. Good, simple production method, environmental protection, long aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

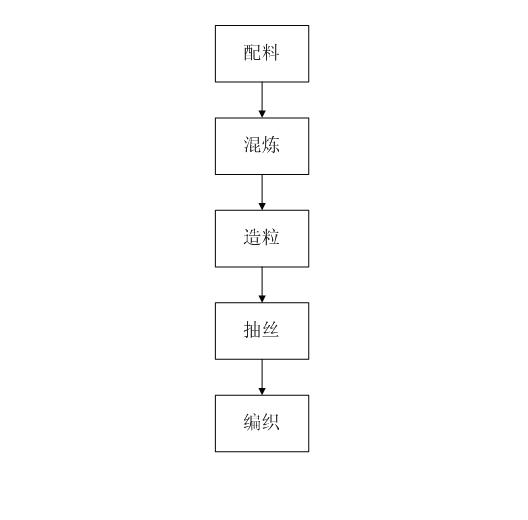

Method used

Image

Examples

Embodiment 1

[0031] First select 100 parts of PE as the main raw material; auxiliary agent: 3 parts of chlorinated polyethylene, 2 parts of coupling agent, and 8 parts of insecticide; fully mix the main raw material and auxiliary agent in the above ratio; melt the above-mentioned mixed raw materials Granulation, the heating temperature is 180°C; then the above-mentioned granulated raw materials are drawn to form insect-removing silk thread with a diameter of 0.5mm; finally, the above-mentioned insect-removing silk thread is used to make an insect-proof and insect-removing fabric on a weaving machine, and the pore size of the fabric is controlled at 1.3mm ~ 1.5mm. The fabric made in this embodiment can be used in screen windows, greenhouses and other occasions that require insect-proof and ventilation.

Embodiment 2

[0033] First select 60 parts of main raw materials PE and 40 parts of PP; auxiliary agents: 5 parts of chlorinated polyethylene, 3 parts of coupling agent, and 10 parts of insecticide; fully mix the main raw materials and auxiliary agents in the above ratio; The raw materials are melted and granulated, and the heating temperature is 200°C; then the above-mentioned granulated raw materials are drawn to form insect-removing threads with a diameter of 1.5mm; finally, the above-mentioned insect-removing threads are used on a weaving machine to make insect-proof and insect-repelling fabrics, and the fabric aperture is The size is controlled between 1.3mm and 1.5mm. The fabric made in this embodiment can be used in screen windows, greenhouses and other occasions that require insect-proof and ventilation.

Embodiment 3

[0035] First, select 100 parts of main raw material PET; additives: 8 parts of chlorinated polyethylene, 5 parts of coupling agent, and 12 parts of insecticide; fully mix the main raw materials and auxiliary agents in the above ratio; melt the above-mentioned mixed raw materials granules at a heating temperature of 190°C; then the above-mentioned granulated raw materials are drawn to form a deworming thread with a diameter of 30 filaments; finally, the above-mentioned deworming thread is used to make an insect-proof and deworming fabric on a weaving machine, and the pore size of the fabric is controlled at 1.3 mm ~ 1.5mm. The fabric made in this embodiment can be used in occasions such as mosquito nets that require insect-proof and ventilation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com