Inverted lead frame and packaging structure thereof

A flip-chip lead and lead frame technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of abnormally sensitive interconnect resistance, high cost, increased loss, etc., and achieve simple and compact structure, low cost, and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

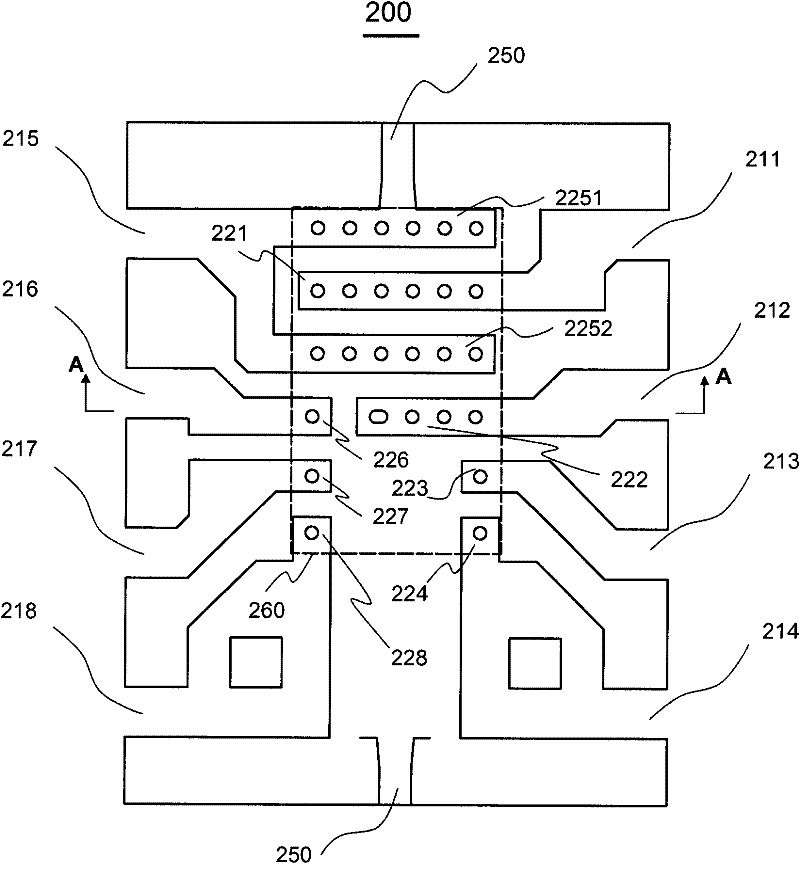

[0035] In the first embodiment, the lead frame of the present invention is described by taking an FCSOIC (Flipchip Small Outline Integrated Circuit Package) lead frame as an example.

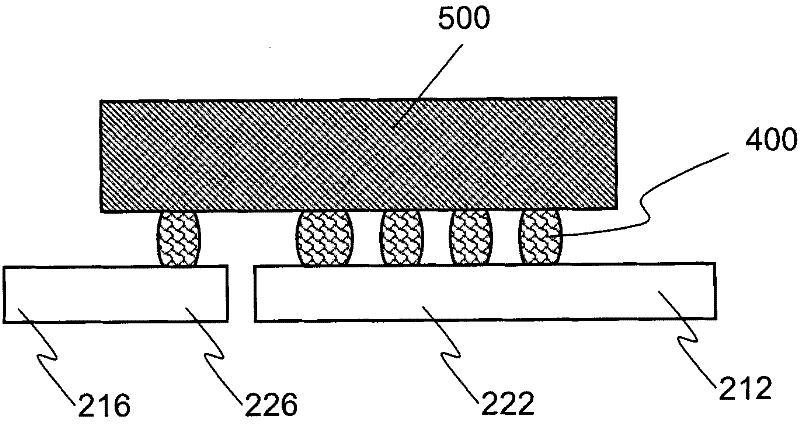

[0036] figure 1 Shown is a schematic structural view of the FCSOIC lead frame provided according to the embodiment of the present invention. Such as figure 1 As shown, in this embodiment, the FCSOIC lead frame 200 includes 8 outer pins and 9 inner pins, however, the number of pins of the FCSOIC lead frame is not limited by the embodiments of the present invention, and those skilled in the art can The circuit functionality of the packaged chip requires the selection of a leadframe with a specific number of pins. FCSOIC lead frame 200 is used for flip-chip welding chip (chip die), wherein the region of dotted line frame 260 is the position where the chip is placed after the lead frame of this embodiment is welded and connected to the chip. In this invention, we will figure 1 The shown dotted fr...

Embodiment 2

[0049] In the second embodiment, the lead frame of the present invention is described by taking an FCTSOT (Flipchip Thin Small Outline Package, Flip Chip Thin Small Outline Package) lead frame as an example.

[0050] Figure 4 Shown is a schematic structural view of the FCTSOT lead frame provided according to the embodiment of the present invention. Such as Figure 4 As shown, in this embodiment, the FCTSOT lead frame 900 includes 5 inner pins, however, the number of pins of the FCTSOT lead frame is not limited by the embodiment of the present invention, and those skilled in the art can according to the circuit function of the packaged chip Requires to select a leadframe with specific number of pins. The FCTSOT lead frame 900 is used for flip chip welding (chip die), wherein the area of the dotted frame 960 is the position where the chip is placed after the lead frame of this embodiment is welded and connected to the chip. In this invention, we will Figure 4 The shown do...

Embodiment 3

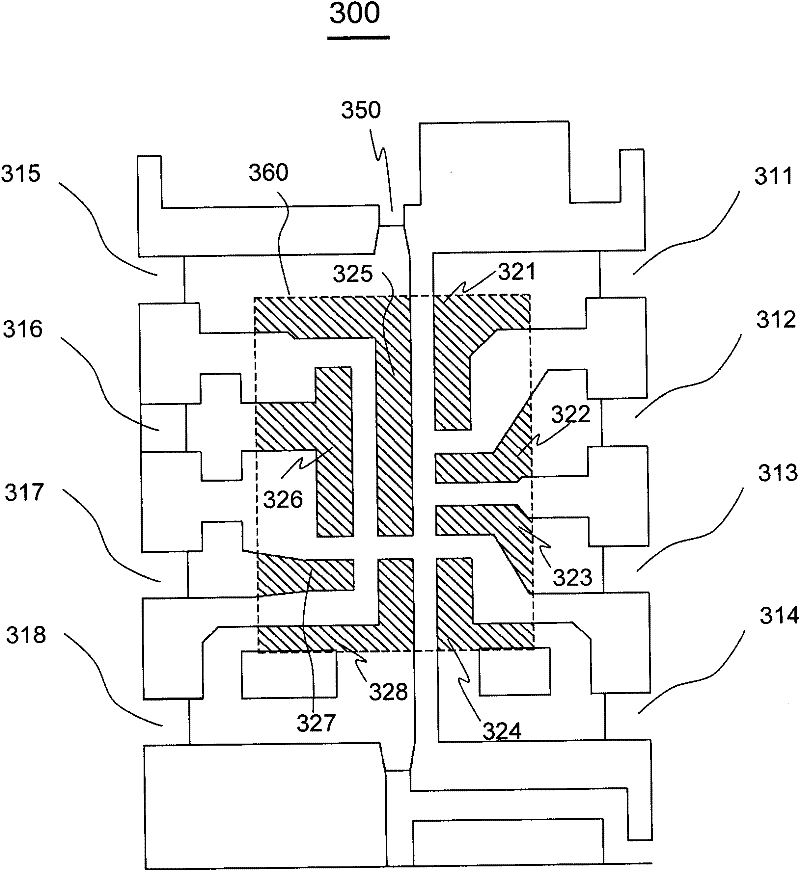

[0059] In the third embodiment, the lead frame of the present invention will be described by taking the lead frame of the Flipchip Thin Quad Flat Non-leaded Package (FCTQFN) as an example.

[0060] Figure 7 Shown is a schematic structural view of the FCTQFN lead frame provided according to an embodiment of the present invention; Figure 8 shown as Figure 7 The schematic diagram of the C-C cross-sectional structure after the lead frame packaged chip is formed into the package structure; Figure 9 shown as Figure 7 The schematic diagram of the D-D cross-sectional structure of the lead frame packaged chip after forming the package structure is shown. Such as Figure 8 with Figure 9 As shown, the invention also provides a packaging structure, which includes figure 2 As shown in the lead frame 700 , the packaged chip 500 and the package body 750 , the chip 500 is directly flip-chip soldered to the lead frame 700 through the ball planting point 760 on the pin of the lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com