Light-emitting module and illumination apparatus

一种发光模块、模块基板的技术,应用在照明装置、照明装置的冷却/加热装置、显示装置等方向,能够解决接合线长度变短等问题,达到减小应力、突出高度适当的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

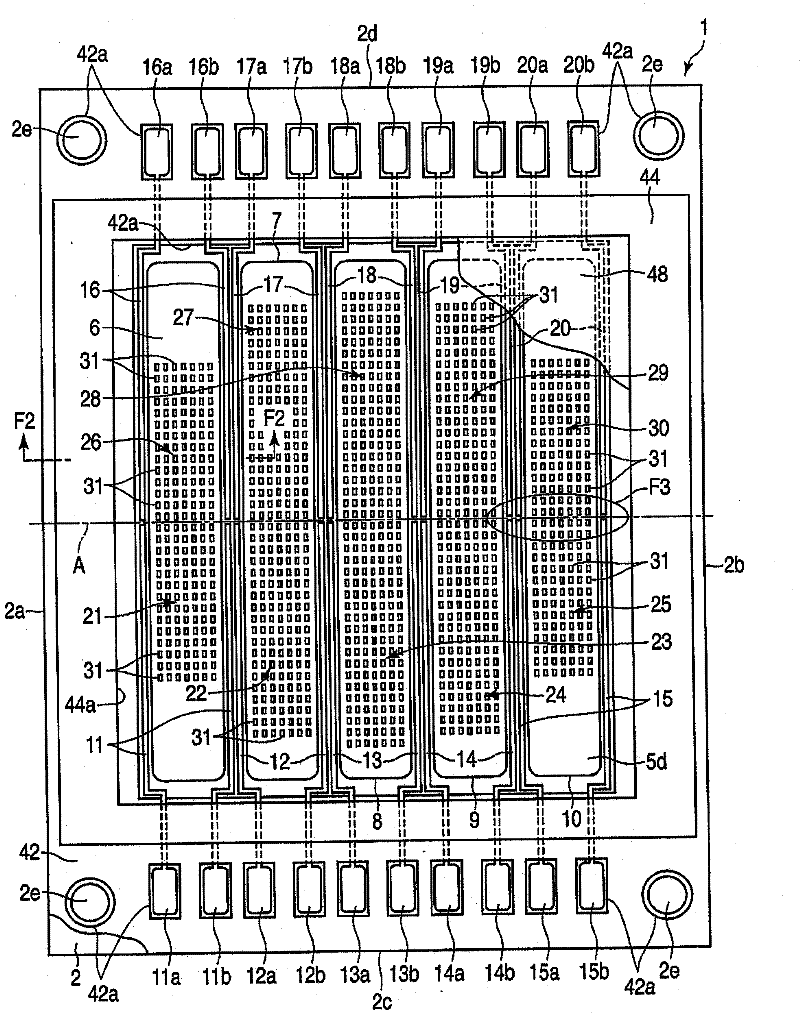

[0089] figure 1 and figure 2 A COB (chip on board: chip on board) type light emitting module 1 is shown. For example, the light emitting module 1 is arranged at the focal point of a projection lens group of a spotlight, and is used as a light source of the spotlight.

[0090] The light emitting module 1 includes a module substrate 2 serving as a base. Such as figure 1 As shown, the module substrate 2 has a rectangular shape having a pair of long sides 2a, 2b and a pair of short sides 2c, 2d. The long sides 2a, 2b are parallel to each other, and the short sides 2c, 2d are also parallel to each other. Also, the module substrate 2 has four corners. Mounting holes 2 e are formed at respective corners of the module substrate 2 .

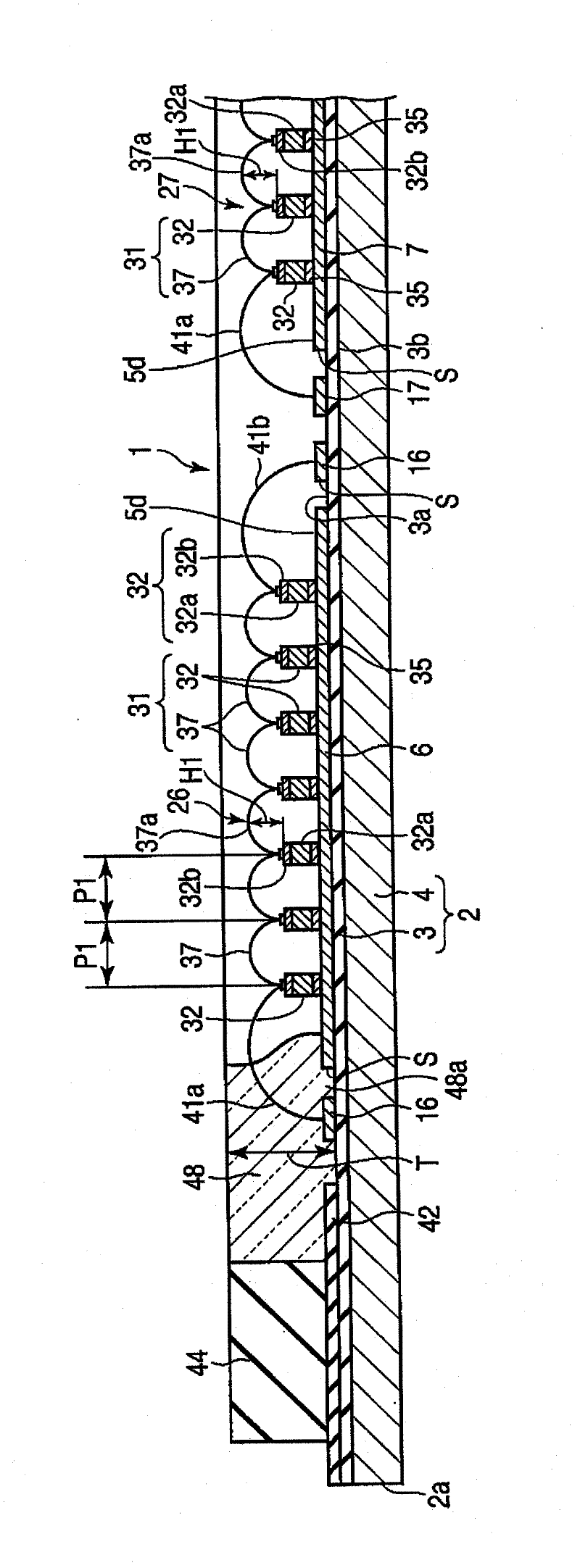

[0091] Such as figure 2 As shown, the module substrate 2 includes a synthetic resin insulating layer 3 and a metal plate 4 . The insulating layer 3 includes a first face 3a and a second face 3b. The second surface 3b is located on the opposite ...

Embodiment approach 2

[0182] Embodiment 2 differs from Embodiment 1 above in matters related to die-bonding materials for bonding light-emitting diode elements to the first to fifth metal reflective layers. The basic structure of the light emitting module except for the die bonding material is the same as that of the first embodiment described above. Therefore, in the second embodiment, the same components as those in the first embodiment are given the same reference numerals, and descriptions thereof are omitted.

[0183] Such as Figure 9 and Figure 10 As shown, the die bonding material 35 is applied so as to cover the first to fifth metal reflective layers 6 to 10 and sandwiched between the silver layer 5 c and the substrate 32 a of each LED element 32 . The die-bonding material 35 covers the entire area except the side edges of the silver layer 5c.

[0184] In other words, the die bonding material 35 continuously covers the region corresponding to the plurality of LED elements 32 , the regi...

Embodiment approach 3

[0202] Embodiment 3 is different from the above-mentioned Embodiment 1 in matters related to die-bonding materials for bonding light-emitting diode elements to the first to fifth metal reflective layers. The basic structure of the light emitting module except for the die bonding material is the same as that of the first embodiment described above. Therefore, in Embodiment 3, the same components as those in Embodiment 1 are given the same reference numerals, and description thereof will be omitted.

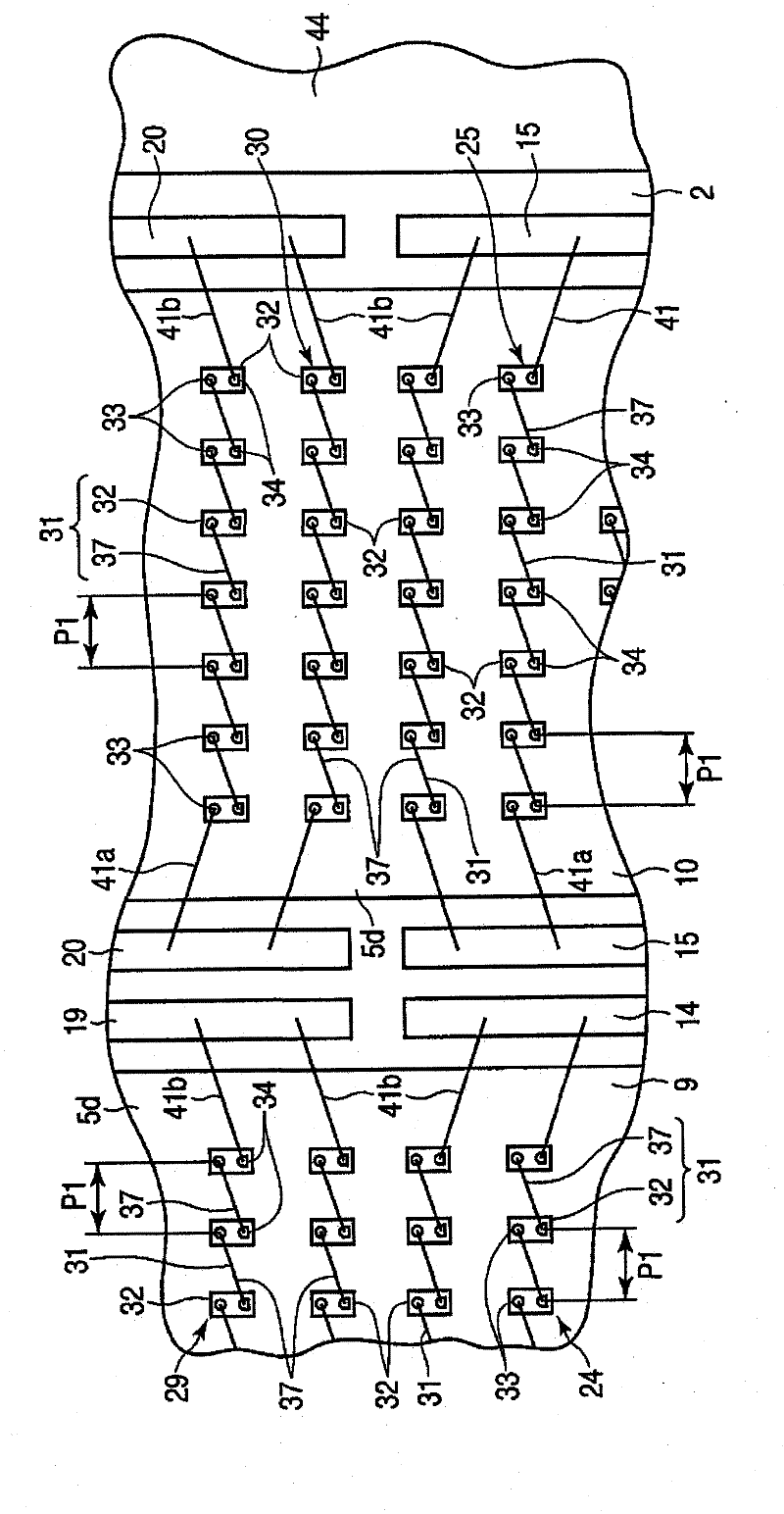

[0203] Figure 11 is corresponding to the above-mentioned Embodiment 1 image 3 The diagram in FIG. 2 mainly shows the states of the fifth and tenth light emitting parts 25 and 30 adhered to the fifth metal reflective layer 10 .

[0204] Such as Figure 11As shown, the die bonding material 35 for bonding the LED elements 32 of the LED row 31 to the light reflective surface 5 d of the fifth metal reflective layer 10 has a plurality of pad portions 51 . The pad portion 51 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com