Process and special device for integrally forming convex navel nut for riveting by using wire rods

A umbilical nut and wire technology, applied in the field of metal forging and pressing, can solve the problems of easy falling off of washers, poor appearance, low material utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

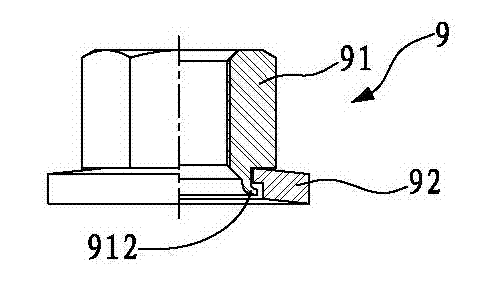

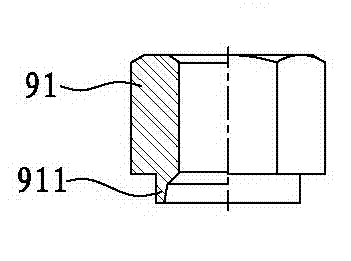

[0055] See Figure 3A to Figure 3G As shown, the cold-drawn hexagonal wire rod used for the coil is sequentially formed by cutting, shaping, preparing the outer circle of the convex navel, final shaping of the outer circle of the convex navel, final forming of the inner corner and height of the convex navel, and final forming of the pre-punched skin. Figure 1B The shown riveting umbilical nut. In order to allow readers of the present invention to better understand the specific implementation of the present invention, there are automatic feeding and automatic clamping operations between the various forming processes of the rivet umbilical nut. Therefore, before describing the manufacturing process of the present invention in detail, first Describe the operation of automatic feeding and automatic pinch feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com