Surface treatment process for plastic product

A surface treatment and product technology, applied in the high hardness process, high stereo vision and high gloss fields, can solve the problems of unstable process, high processing cost and high cost, and achieve simple operation, strong three-dimensional effect and low processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

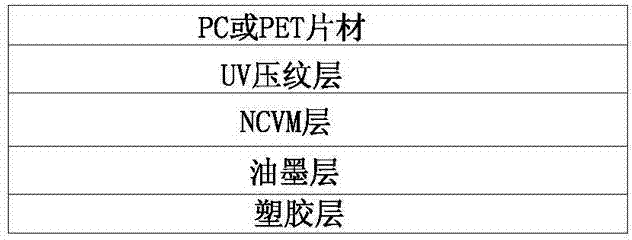

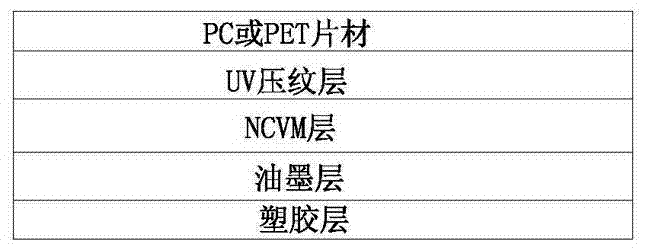

[0024] 1) Select a PET substrate with a thickness of 0.1mm, and apply UV topcoat to the surface of the PET substrate. When coating the UV topcoat, the temperature is 25°C and the humidity is 50%. The electroforming mold is used to press the surface of the UV topcoat. Textures, so that the surface of the UV topcoat forms a three-dimensional texture, and then the PET substrate is placed in a UV furnace for curing to form a UV embossed layer. The thickness of the applied UV topcoat is not limited, and it is set according to the different needs of different customers.

[0025] 2) Carry out vacuum sputtering electroplating NCVM on the UV embossed layer, and the vacuum pressure during vacuum sputtering electroplating NCVM is 0.001Pa, so that the surface of the UV embossed layer can be sputtered and electroplated with various desired appearance colors.

[0026] 3) Then print the ink layer on the NCVM layer to form various patterns.

[0027] 4) Die-cut the printed PET base material t...

Embodiment 2

[0031] 1) Select a PET substrate with a thickness of 0.125mm, and apply UV topcoat to the surface of the PET substrate. When coating the UV topcoat, the temperature is 23°C and the humidity is 55%, and the electroforming mold is used to press the surface of the UV topcoat. Textures, so that the surface of the UV topcoat forms a three-dimensional texture, and then the PET substrate is placed in a UV furnace for curing to form a UV embossed layer. The thickness of the applied UV topcoat is not limited, and it is set according to the different needs of different customers.

[0032] 2) Carry out vacuum sputtering electroplating NCVM on the UV embossed layer, and the vacuum pressure during vacuum sputtering electroplating NCVM is 0.001Pa, so that the surface of the UV embossed layer can be sputtered and electroplated with various desired appearance colors.

[0033] 3) Then print the ink layer on the NCVM layer to form various patterns.

[0034] 4) Die-cut the printed PET base mate...

Embodiment 3

[0038] 1) Select a PC sheet with a thickness of 0.175mm, and apply UV topcoat to the surface of the PC sheet. When coating the UV topcoat, the temperature is 27°C and the humidity is 60%. Use an electroforming mold to press the surface of the UV topcoat. Textures, so that the surface of the UV topcoat forms a three-dimensional texture, and then the PC sheet is cured in a UV furnace to form a UV embossed layer. The thickness of the applied UV topcoat is not limited, and it is set according to the different needs of different customers.

[0039] 2) Carry out vacuum sputtering electroplating NCVM on the UV embossed layer, and the vacuum pressure during vacuum sputtering electroplating NCVM is 0.001Pa, so that the surface of the UV embossed layer can be sputtered and electroplated with various desired appearance colors.

[0040] 3) Then print the ink layer on the NCVM layer to form various patterns.

[0041] 4) Die-cut the printed PET base material to form a sheet, and the size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com