Snow compressor

A compressor and snow powder technology, applied in the field of compression machinery, can solve the problems of large specific surface area, fine particle size of snow powder, large air friction resistance, etc., and achieve the effect of reducing the accumulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

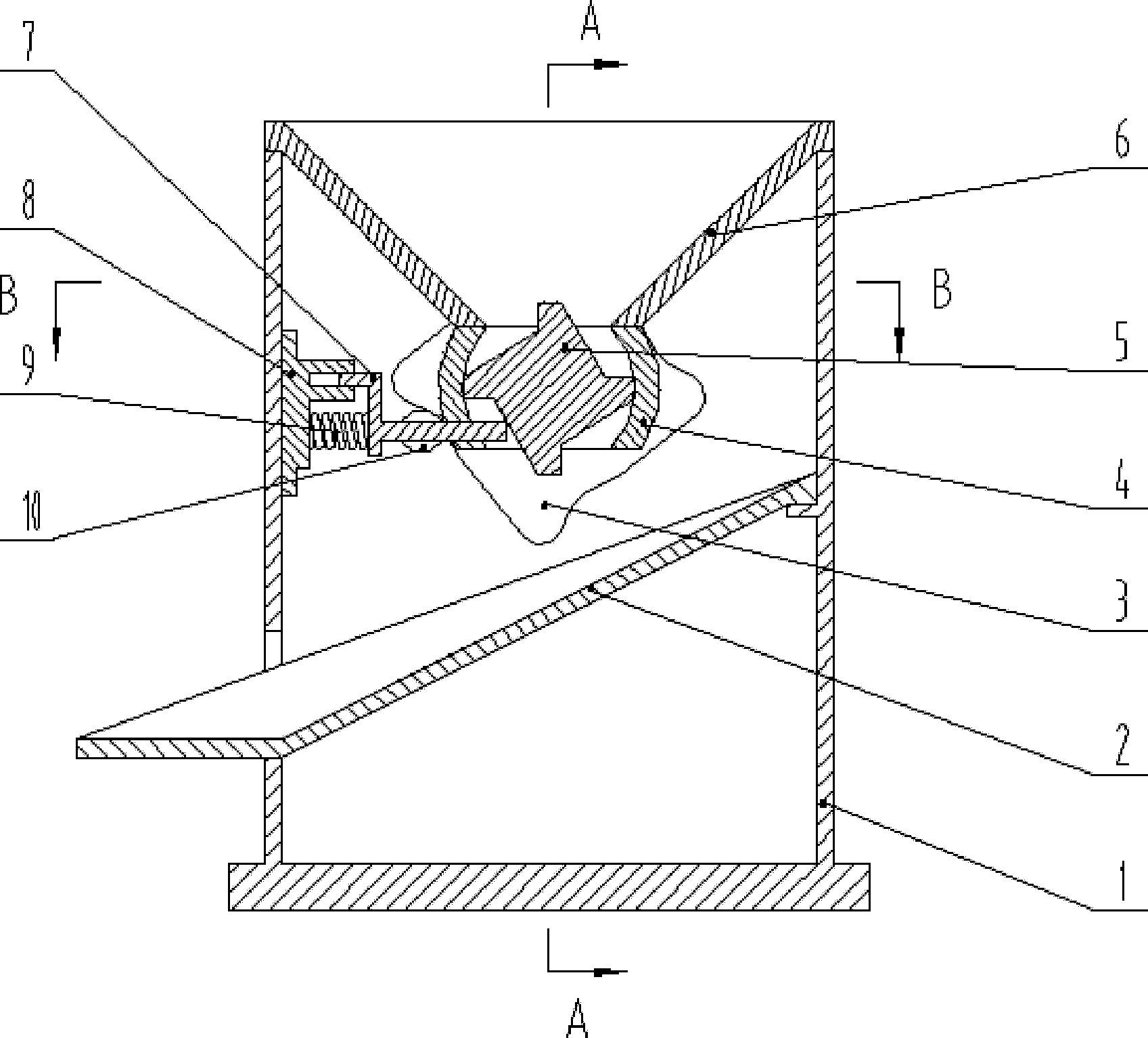

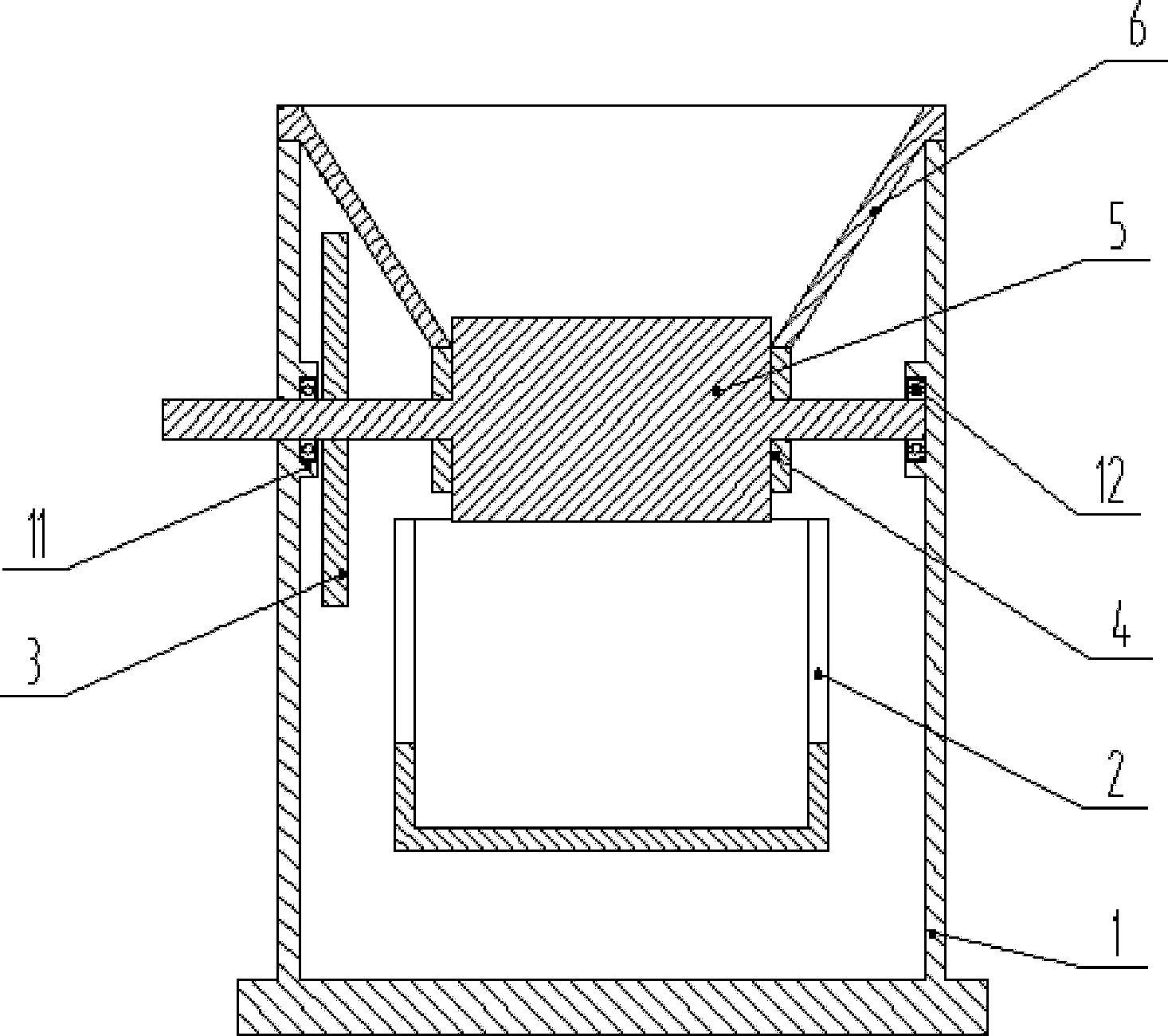

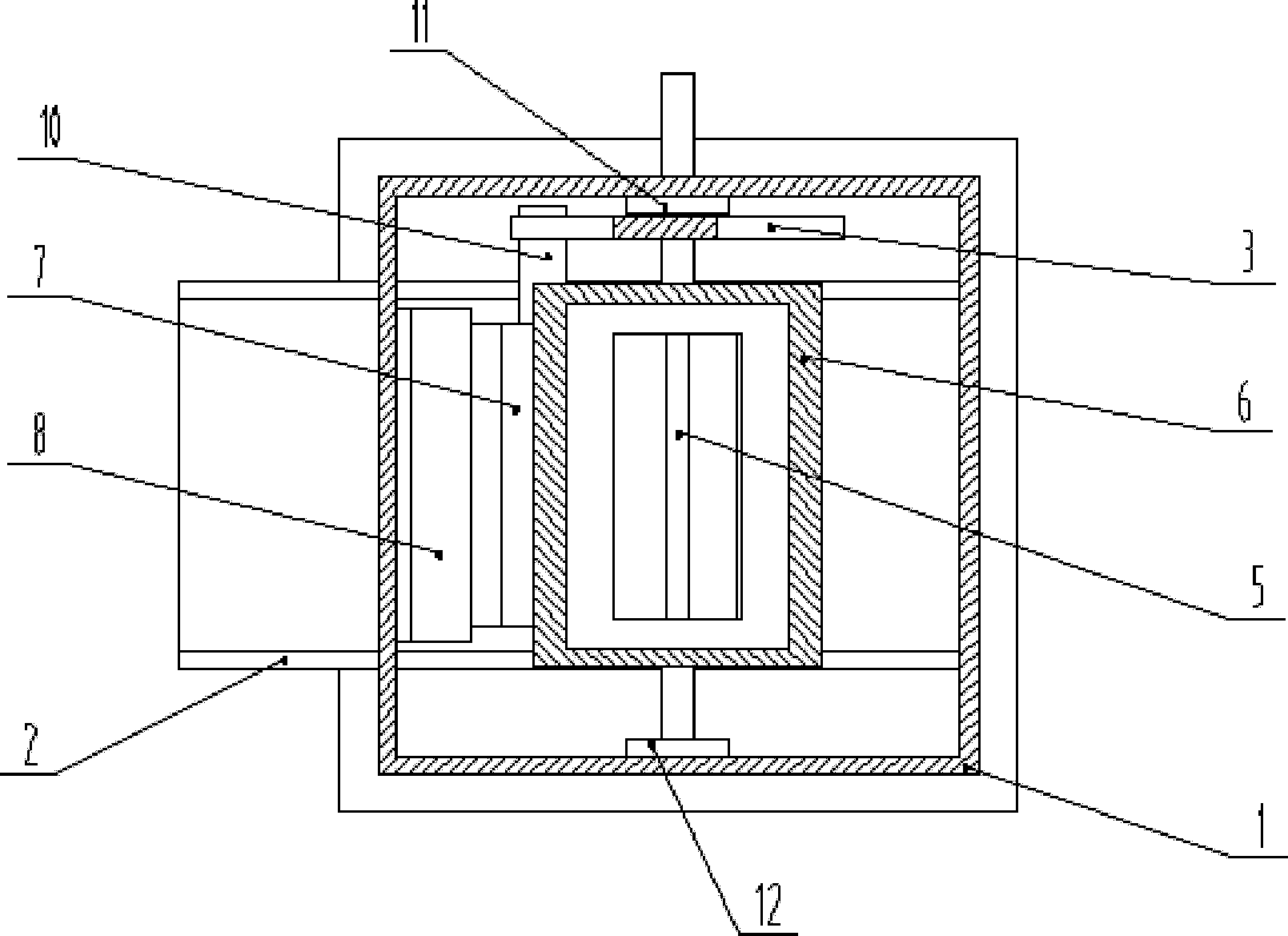

[0017] A snow powder compressor of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 , figure 2 with image 3 A snow powder compressor is shown, which consists of a body 1, a discharge chute 2, a cam 3, a compression cylinder 4, a compression roller 5, a feed hopper 6, a tongue plate 7, a tongue plate seat 8, a spring 9, a roller 10, a front Bearing 11 and rear bearing 12; wherein the body 1 is a square cylinder structure with a lower end connected to a bottom plate, an upper end open, and placed vertically; the feeding hopper 6 is a square funnel structure, placed at the upper end of the body 1; The compression cylinder 4 is in the shape of a barrel placed horizontally on the lower opening of the feed hopper 6. The upper and lower axial lengths of the compression cylinder wall of the compression cylinder 4 correspond to openings, and a notch is opened on the lower axial length of the center of one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com