Polyester/polyethylene/carbon nanotube ternary composite material and preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of polymer composite material preparation, can solve the problems of incapable of industrialized production and complex preparation methods of composite materials, and achieves the effect of easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention relates to a polyester / polyethylene / carbon nanotube ternary composite material and a preparation method thereof, which are realized through the following steps:

[0032] Take by weighing dry carbon nanotube 1.8g, high-density polyethylene 42g (melt index is 7g / 10min), polybutylene terephthalate cyclic oligomer 18g, polyester catalyst 0.036g, add banburying Blending in a machine at a temperature of 235° C. for 10 minutes and a rotation speed of 70 rpm to obtain a polybutylene terephthalate / high-density polyethylene / carbon nanotube ternary composite material with good compatibility.

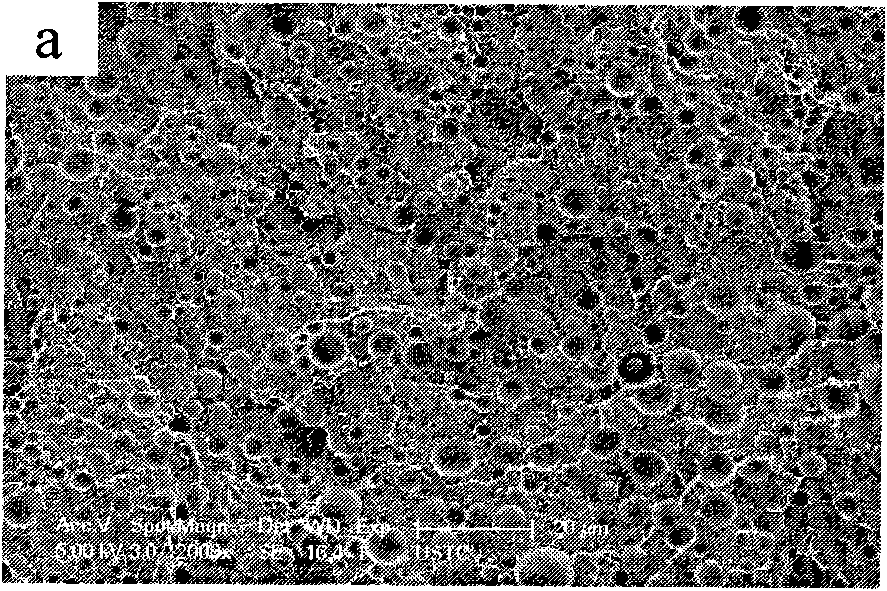

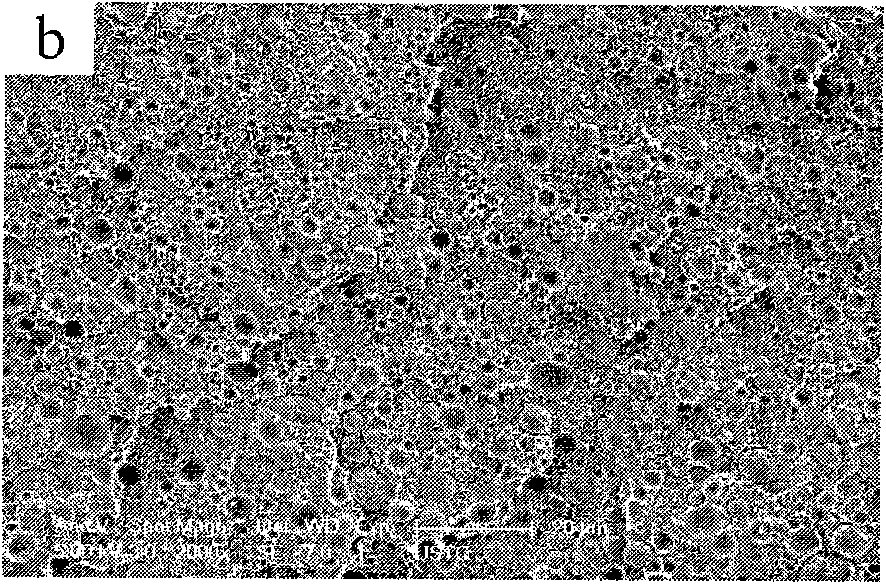

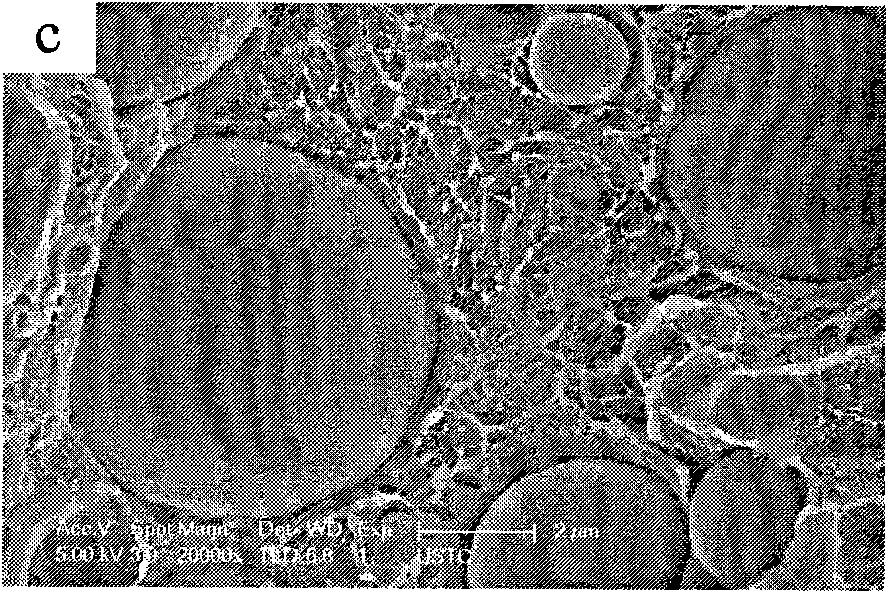

[0033] The prepared ternary composite was characterized by field emission scanning electron microscopy (FESEM). Since carbon nanotubes acted as compatibilizers in the polyester / polyethylene incompatible system, the compatibility of the two phases was improved. See attached figure 1 , as can be seen from the figure, the interface between the two phases becomes blurred due to th...

Embodiment 2~5

[0035]

[0036] Polybutylene terephthalate cyclic oligomer (g)

[0037] According to the method for Example 1, the polyester / polyethylene / carbon nanotube ternary composite material of Example 2-5 is obtained, and the prepared ternary composite material is characterized by a field emission scanning electron microscope (FESEM). In the polyester / polyethylene incompatible system, it acts as a compatibilizer, and the compatibility of the two phases is improved.

Embodiment 6

[0039] A kind of preparation method of polyester / polyethylene / carbon nanotube ternary composite material, the method comprises the following steps:

[0040] (1) Prepare raw materials according to the following components and parts by weight:

[0041] Polyethylene 10 with a melt index of 0.2 g / 10 min;

[0042] Polytrimethylene terephthalate cyclic oligomer 90;

[0043] Carbon nanotubes 5 with a length of 10 microns and a diameter of 10 nm;

[0044] Butyl dihydroxytin chloride 0.18;

[0045] (2) Add the above raw materials into an internal mixer, blend at a temperature of 230° C. for 10 minutes, and rotate at a speed of 100 rpm to prepare a polyester / polyethylene / carbon nanotube ternary composite material with good compatibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com