Gas exhaust and heat insulation plate

A technology of heat insulation board and exhaust pipe, which is applied to exhaust devices, mufflers, engine components, etc., can solve the problems of insufficient space, increased manufacturing cost, insufficient layout space, etc., and achieves compact and simple structure and low manufacturing cost. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

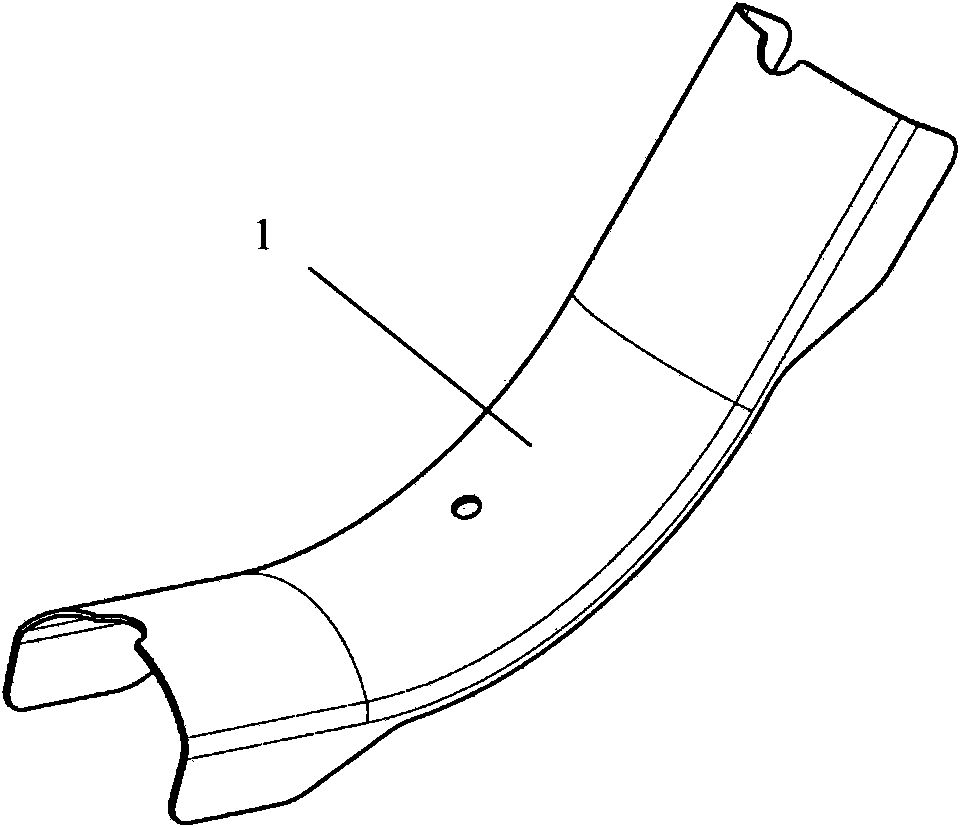

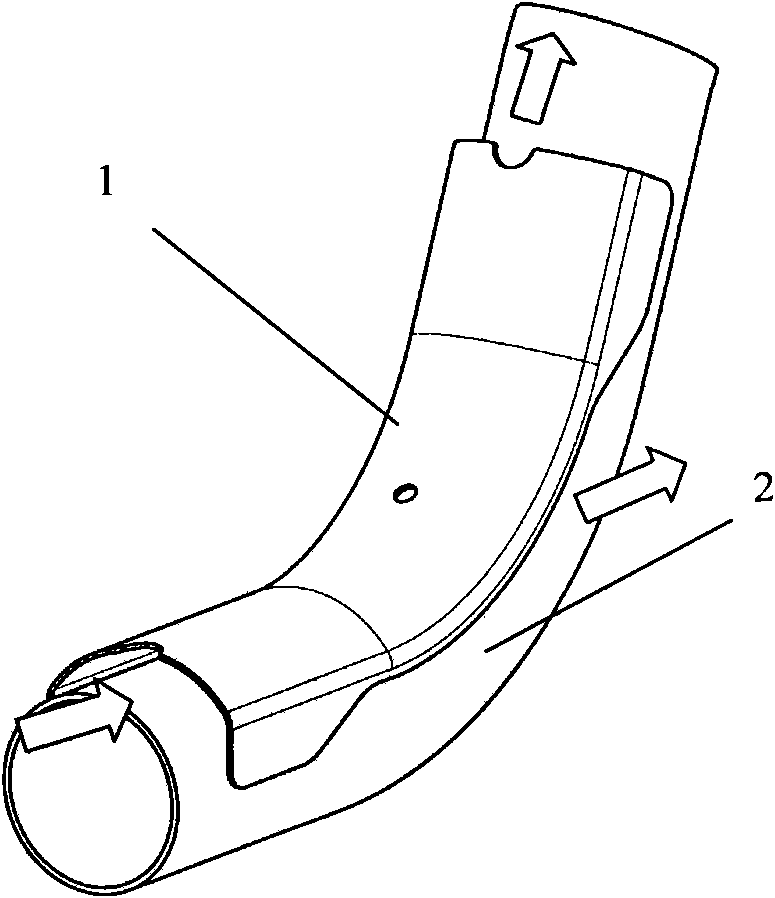

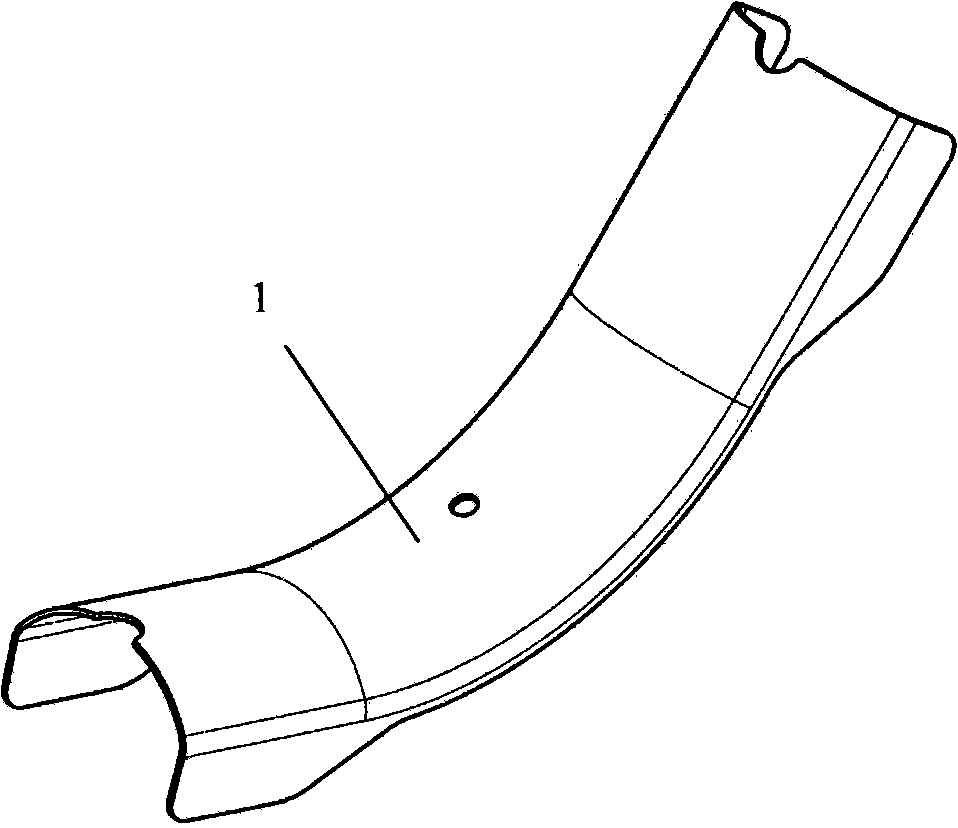

[0011] The exhaust heat insulation board is composed of the exhaust pipe 2 and the heat insulation board 1. It is characterized in that: the heat insulation board 1 is installed on the exhaust pipe 2, and the heat insulation board 1 partly surrounds the circumference of the exhaust pipe 2 for heat insulation. There is a gap between the plate 1 and the exhaust pipe 2 .

[0012] Such as figure 1 and figure 2 As shown, in the development process of the A130 project, in view of the situation that the hot-end exhaust pipe 2 of the exhaust system is close to the transmission shaft protective sleeve and other parts are far away, as figure 2 As shown, the heat shield 1 is welded to the exhaust pipe 2. The heat shield 1 does not wrap the entire exhaust pipe 2, but only wraps the part of the exhaust pipe 2 opposite to the transmission shaft protection sleeve, and the heat shield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com