Static leveling device and system

A technology of static leveling and measuring devices, applied in the field of detection, can solve problems such as large test errors, large influence on measurement results, poor reproducibility and stability, etc., to improve measurement accuracy, eliminate manual intervention factors, reduce The effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

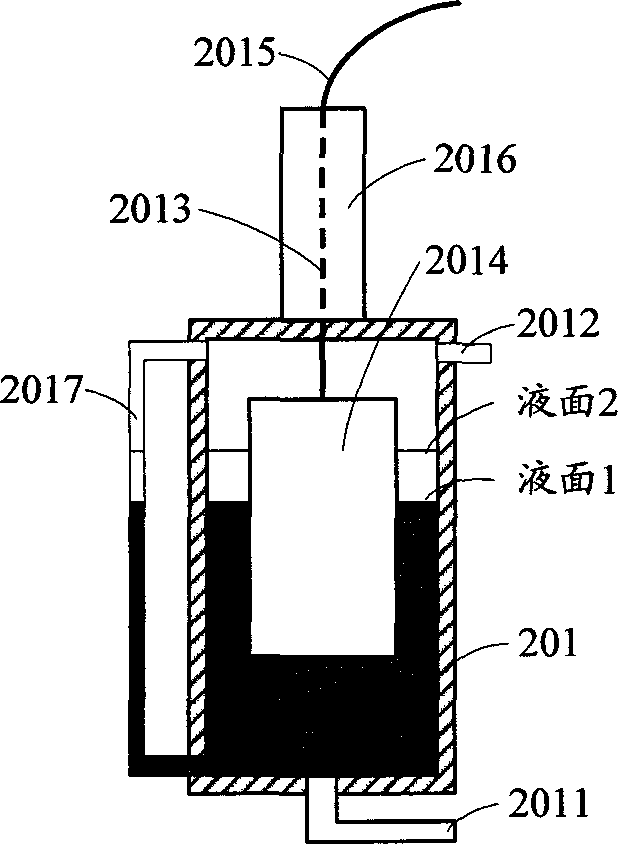

[0056] figure 2 It is a structural schematic diagram of the static level measuring device in the present invention. Such as figure 2 As shown, in the static level measuring device in the present invention, mainly include: level box 201, buoy bucket 2014, vibrating wire type force sensor 208, wherein,

[0057] There is an internal cavity in the level box 201; the bottom of the level box 201 is provided with a water supply and drainage pipe 2011 for water injection and drainage; the top of the level box 201 is provided with an air pressure for ensuring the internal cavity of the level box Airflow pipe 2012 consistent with external air pressure;

[0058] The vibrating wire force sensor 208 is arranged on the top of the level box 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com