Directive thermosyphon-type heat conducting column

A thermosyphon and directional technology, which is applied in semiconductor devices, cooling/ventilation/heating transformation, semiconductor/solid-state device components, etc., can solve problems such as inability to achieve circulation and heat dissipation effects that cannot reach the best state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

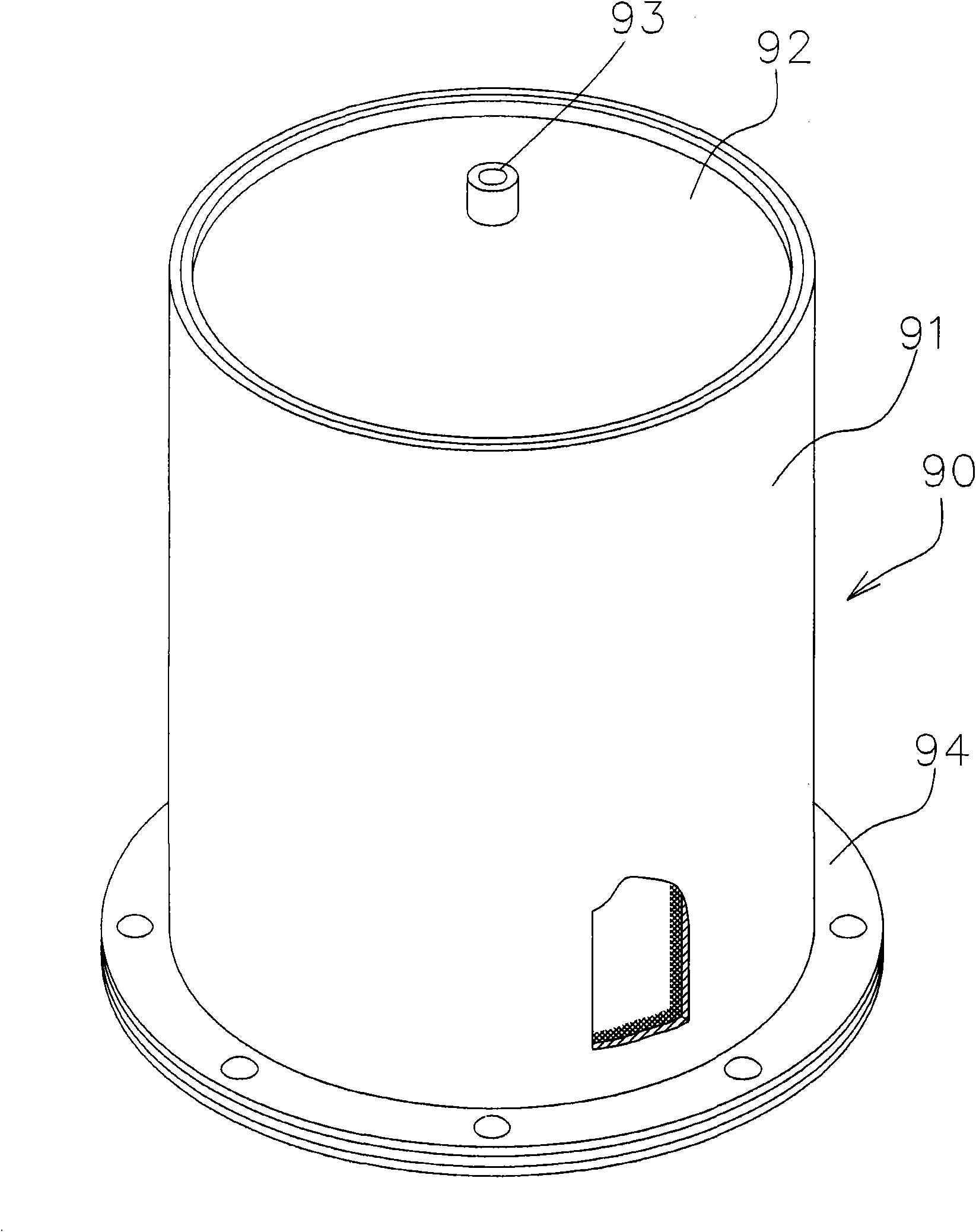

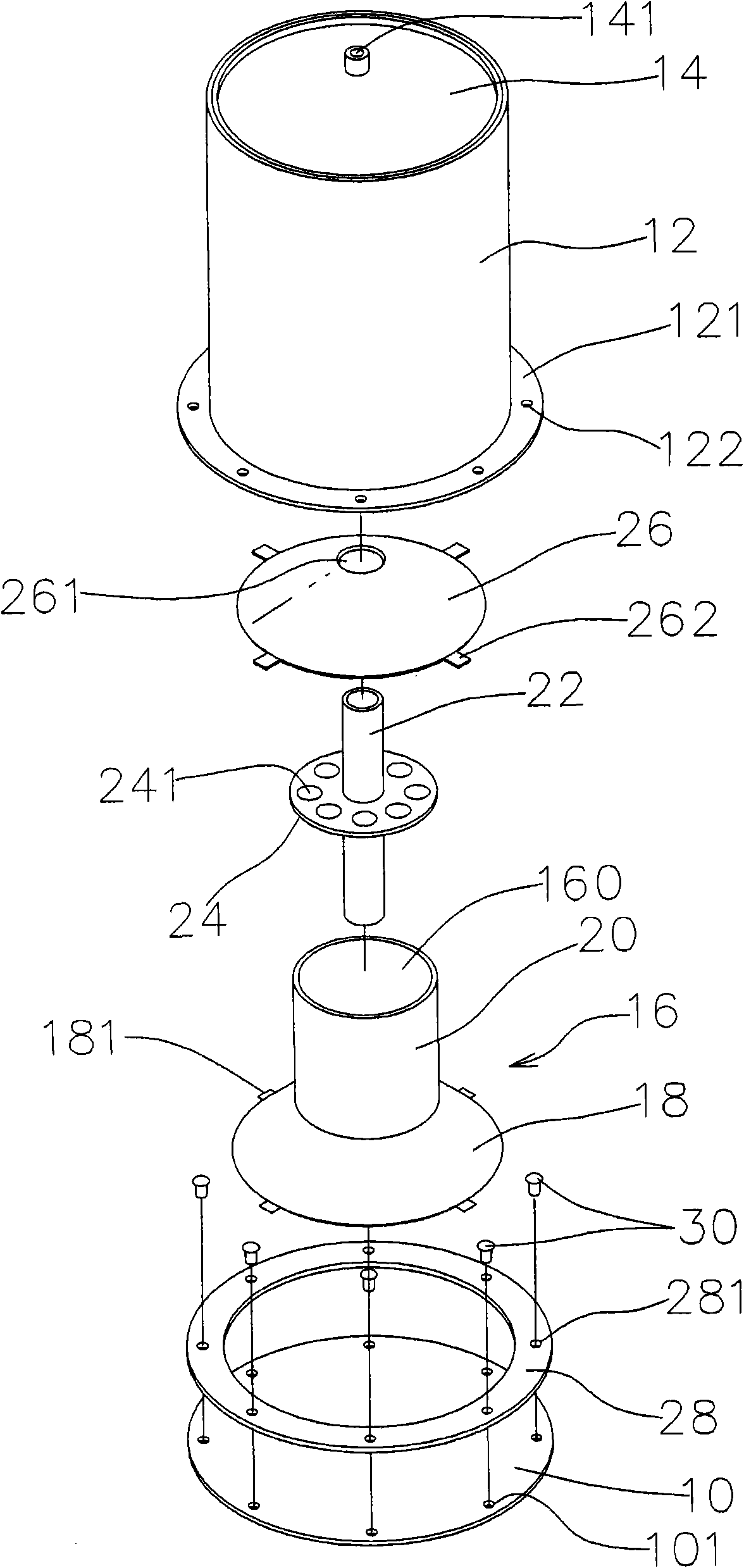

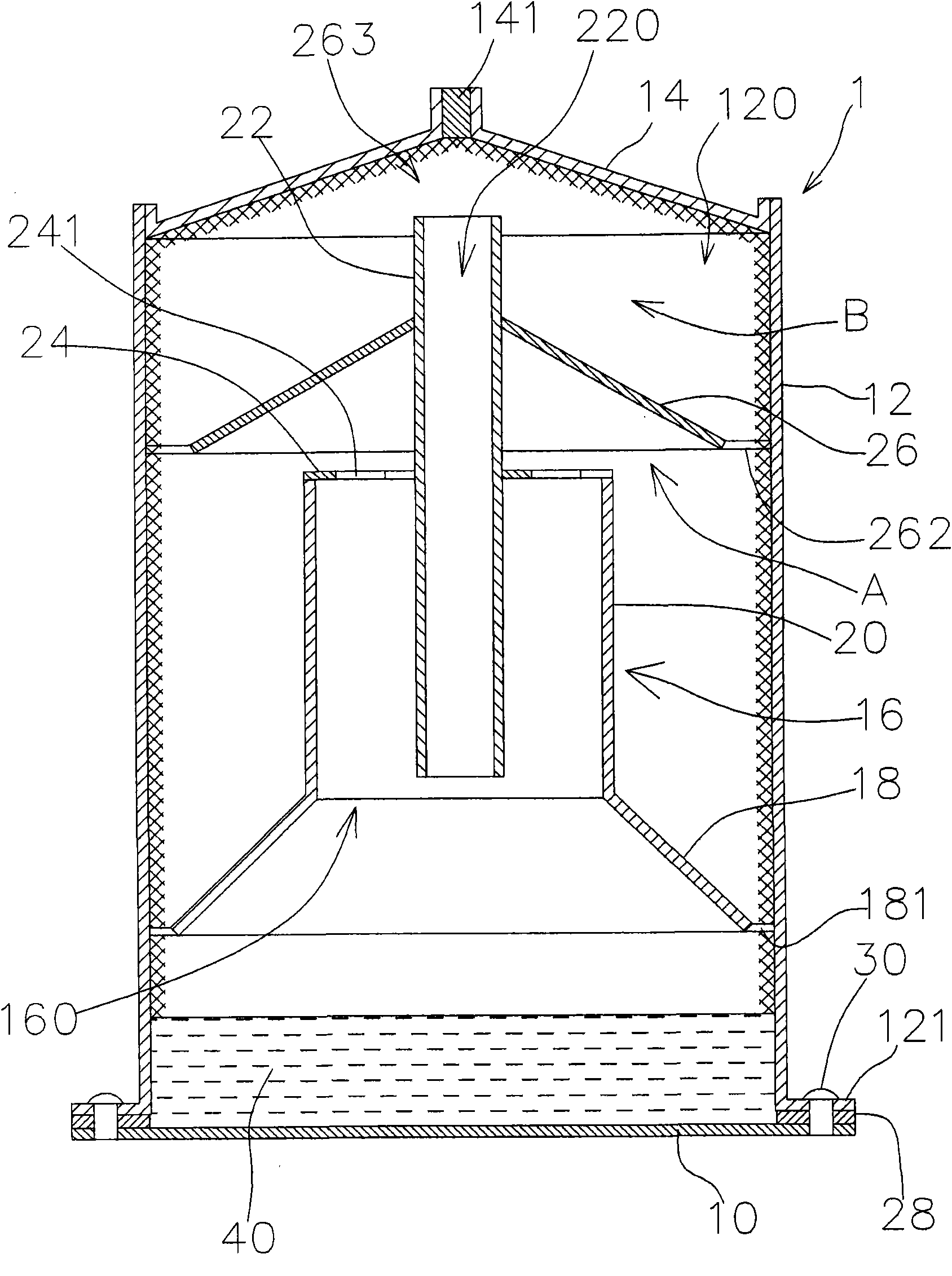

[0029] see figure 2 , image 3 , which is a schematic diagram of the first preferred embodiment of the directional thermosiphon heat conduction column of the present invention, which includes a heat conduction column 1, and the heat conduction column 1 further includes a cylinder 12, a guide 16 and a partition 26. The column 12 is a hollow cavity, that is, the column 12 has an action space 120 inside, and the inner wall surface of the column 12 is provided with metal crystals, metal powder sintered blocks or copper mesh on the inner wall surface of the action space 120 or capillary structures such as grooved pipes or mesh pipes, the bottom end of the cylinder 12 is provided with a protruding end edge 121 (the upper and lower directions or the front and rear directions referred to in the present invention are according to the orientation of the figure. For example, the application is not limited to the vertical setting), the upper ring of the connecting edge 121 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com