Heat-radiating structure of frequency converter

A technology of heat dissipation structure and frequency converter, which is applied in the direction of cooling/ventilation/heating transformation, output power conversion device, electrical components, etc. It can solve the problems that do not conform to the development trend of light products, difficult to reduce product costs, and large radiators. , to achieve the effect of increasing heat dissipation, reducing volume, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The applicant now describes in detail the specific implementation of the technical solution according to the accompanying drawings.

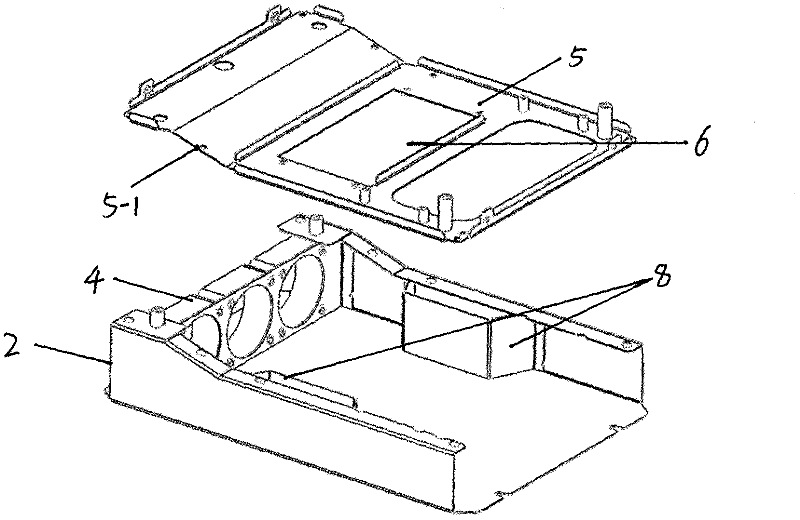

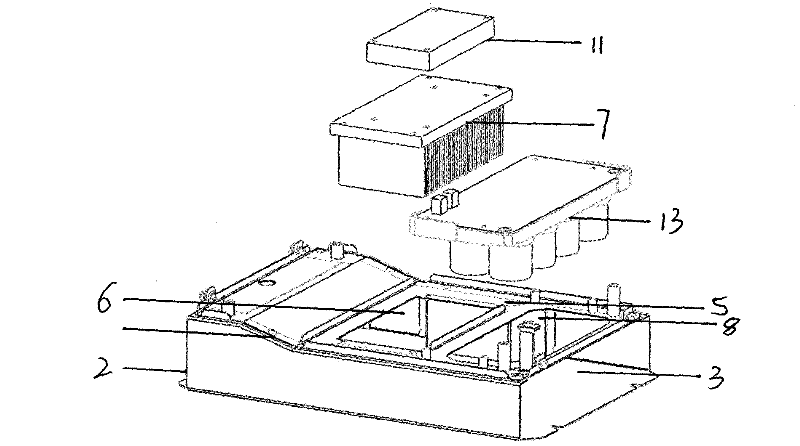

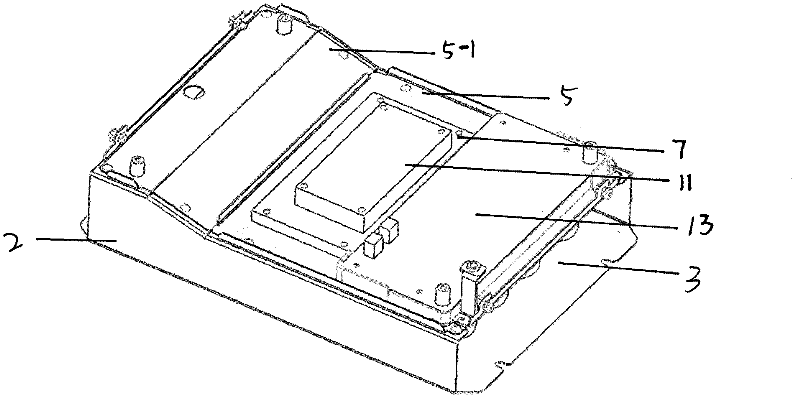

[0020] Such as Figure 1-Figure 4 Shown is an embodiment of the heat dissipation structure of the low-power inverter. The shell of the frequency converter can be selected according to the needs whether the upper shell 1 and the lower shell 2 are buckled together or constituted by a whole piece of shell 12. Here, the applicant chooses whether the shell of the low-power frequency converter is buckled up and down. , the cooling air duct is located in the lower casing 2, the cooling air duct 3 is left and right through, the left side is the air outlet, the right side is the air inlet, the air duct inner plate 5 is located on the cooling air duct 3, and is fixed on the lower housing 2, The fixing method can be welding or bending the two sides of the lower casing 2 inwards and fixing them with screws. There is a square hole 6 matching the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com