Light-emitting unit array, method for fabricating the same and projection apparatus

A technology of light-emitting units and projection equipment, applied in the direction of optical components, optical components, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0050] In this embodiment, a micro light-emitting diode (LED) array is realized by adjusting the thickness and structure of the epitaxial structure of the LED so as to optimize light extraction or light collimation to meet the requirements.

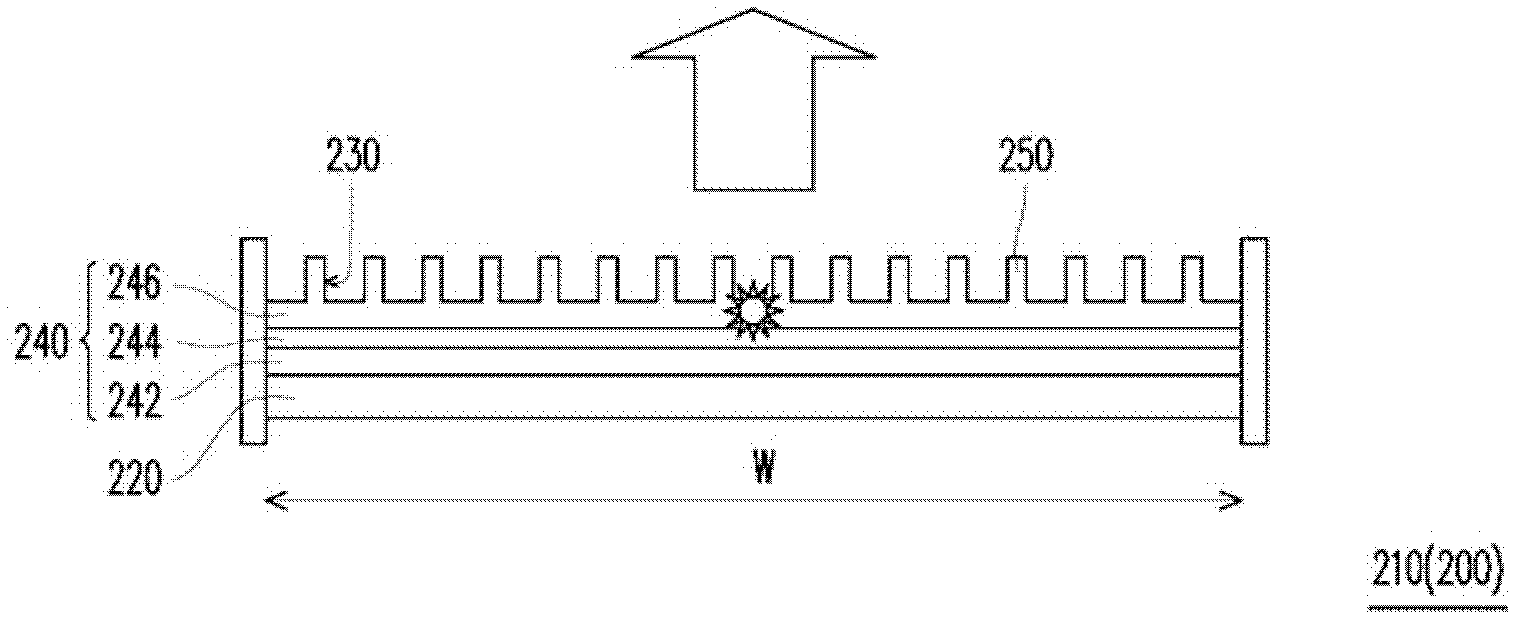

[0051] figure 1 is a schematic cross-sectional view of the micro LED array according to the first embodiment of the present invention. It should be noted that the micro LED array 200 has a plurality of micro LEDs arranged in an array and monolithically integrated, and for clarity of description, figure 1 Only the cross-sectional structure of one micro-LED in the micro-LED array is shown. see figure 1 , the micro LED 210 of the present embodiment comprises a reflective layer 220 and a light-emitting layer 240, wherein the light-emitting layer 240 comprises, for example, a P-type epitaxial layer 242, an N-type epitaxial layer 246, and a multiple quantum well sandwiched between these two epitaxial layers (multiple quantum well, MQW) 244 (...

no. 2 example

[0062] In this embodiment, the method of manufacturing a micro LED array is implemented by adding a sacrificial layer in specific steps and in specific positions of the micro LEDs, so as to simplify the overall manufacturing process of the micro LED array with higher light extraction and higher light collimation.

[0063] Figures 3A to 3E is a schematic cross-sectional view illustrating a process flow of a micro LED array according to a second embodiment of the present invention.

[0064] see Figure 3A , first provide a substrate 310 . The material of the substrate 310 is, for example, sapphire. In addition, the sacrificial layer 340 is added in the epitaxial stack layer intended to form the micro-LED structure, so that the micro-LED 300 can easily achieve the desired thickness of the micro-cavity resonance. More specifically, the undoped gallium nitride (un-GaN) layer 320, the first n-type doped gallium nitride (n-GaN) layer 330, the sacrificial layer 340, the second n-G...

no. 3 example

[0076] In this present embodiment, a micro-LED array is implemented for tuning the external field distribution of the micro-LEDs in order to optimize light extraction and light collimation to meet requirements. In some embodiments, the micro LED array can also reduce cross-talking.

[0077] Figures 5A to 5D is a schematic cross-sectional view illustrating a process flow of a micro-optical lens structure of a micro-LED array according to a third embodiment of the present invention, wherein the micro-LED array in this embodiment further includes a micro-optical lens structure, and LEDs are correspondingly disposed therein . For better illustration, Figures 5A to 5D Only the micro-optical lens structure is shown, and the micro-LED disposed therein is omitted. The micro LED array can be any of the micro LED arrays mentioned above or any other kind of micro LED array, this embodiment is not limited in terms of the type of micro LED array.

[0078] see Figure 5A , forming th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com