Flexible substrate

A flexible substrate, ductility technology, applied in dielectric properties, thermoplastic polymer dielectrics, transportation and packaging, etc., to achieve high reliability, reliable bonding, and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

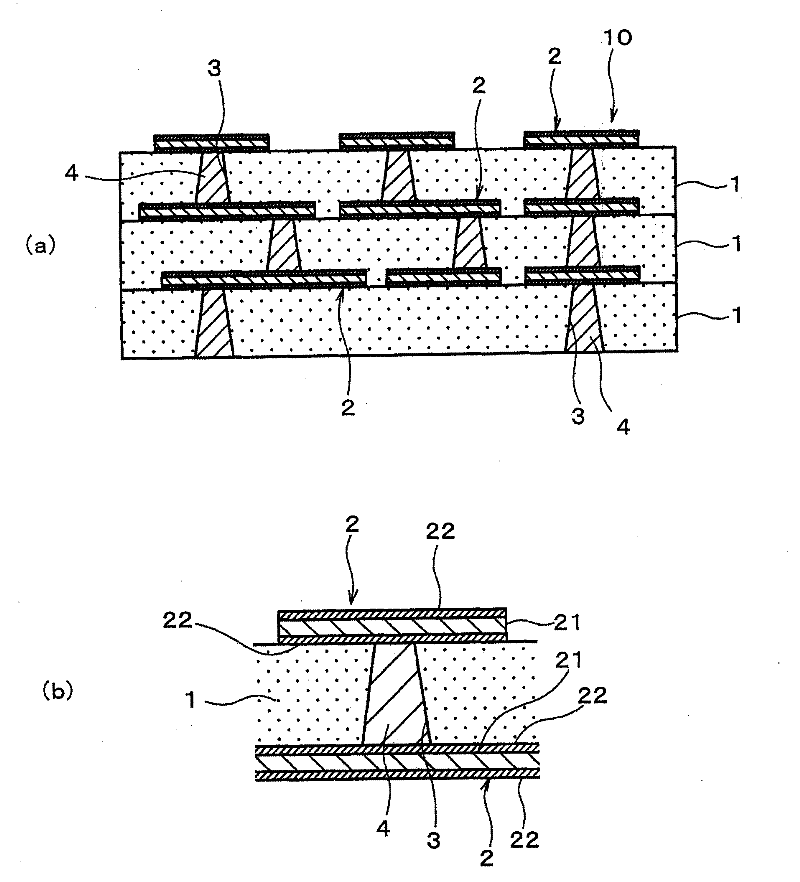

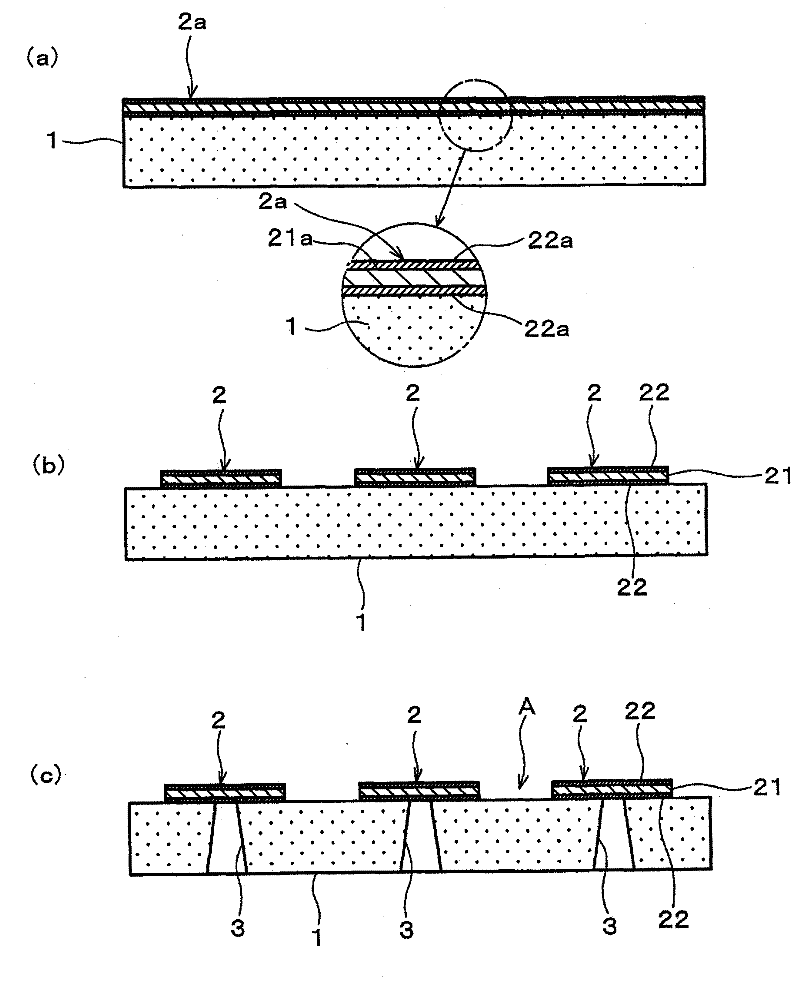

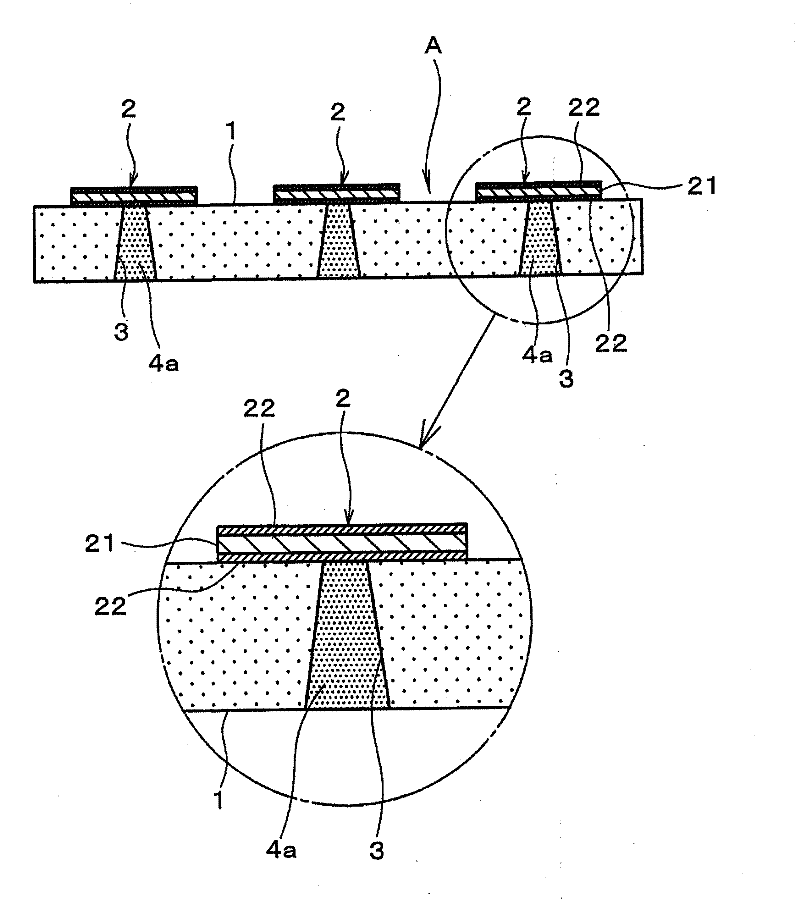

[0048] figure 1 Schematically represents the structure of a flexible substrate (flexible multilayer substrate) according to an embodiment of the present invention, figure 1 (a) is a front sectional view, figure 1 (b) is an enlarged cross-sectional view showing a main part in an enlarged manner.

[0049] Such as figure 1 As shown in (a) and (b), the flexible substrate (flexible multilayer substrate) 10 includes: a resin layer (a thermoplastic resin layer in this embodiment 1) 1 constituting a base material layer; 1 and a conductor layer (conductor pattern) 2 having a predetermined pattern; 3 is provided on the thermoplastic resin layer 1.

[0050] In this flexible multilayer substrate 10 , the thermoplastic resin layer 1 is formed of a thermoplastic resin having a melting point of 250° C. or higher, such as liquid crystal polymer (LCP) or polyether ether ketone (PEEK).

[0051] Also, the thermoplastic resin layer 1 can have desired flexibility by adjusting its thickness or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com