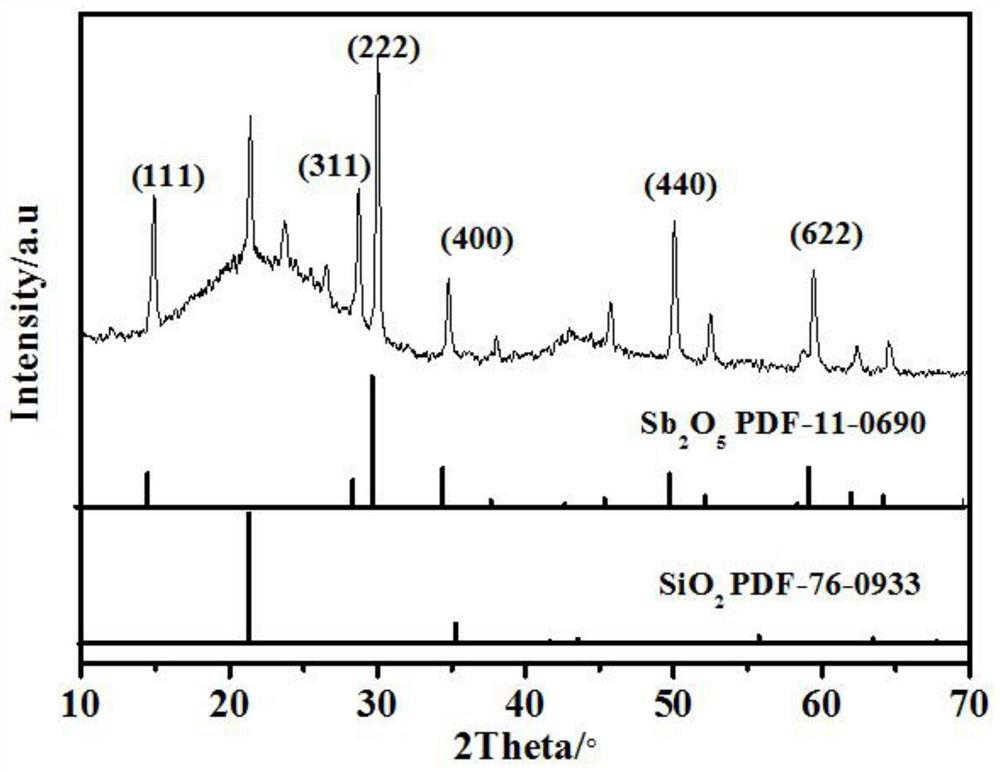

Preparation of a flexible antimony pentoxide/silicon dioxide/carbon cloth material and its application as a negative electrode for sodium-ion batteries

An antimony pentoxide and sodium ion battery technology is applied in the preparation/purification of antimony oxide/antimony hydroxide/antimony oxyacid, silicon dioxide, carbon, etc., which can solve problems such as incompatibility, achieve low cost, High specific capacity properties, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

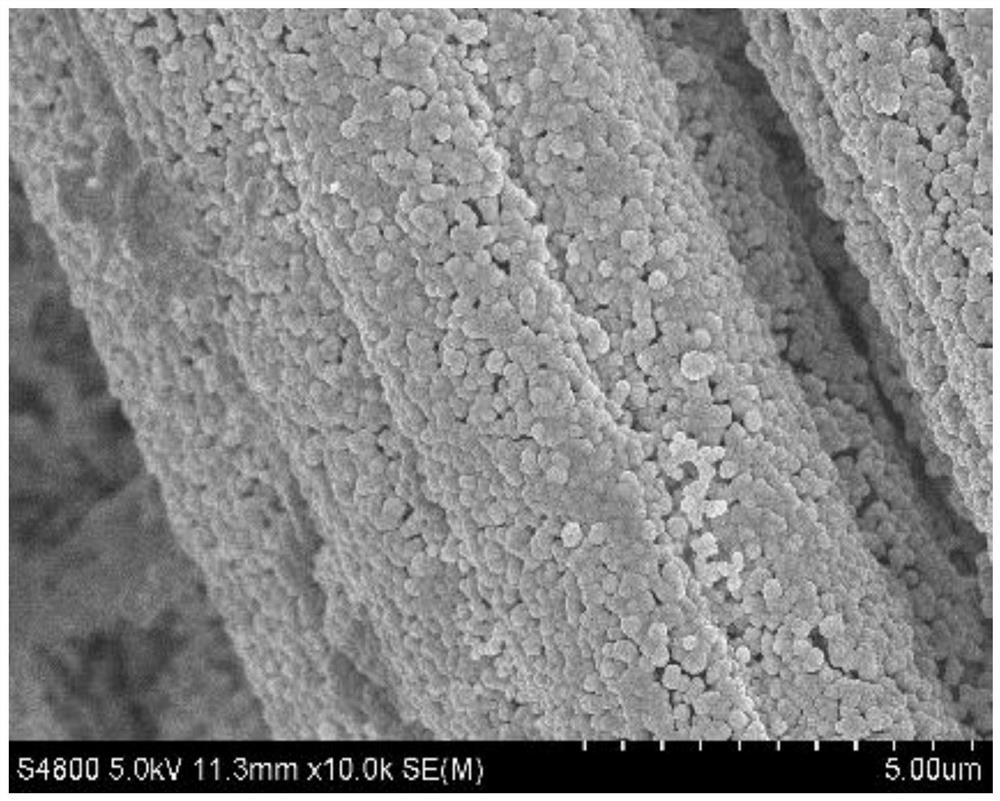

Embodiment 1

[0029] The preparation of a kind of antimony pentoxide / silicon dioxide / carbon cloth flexible material comprises the following steps:

[0030] Step 1: Grind 0.038g of silica particles and add them into 20ml of deionized water for ultrasonic treatment for 1h and dissolve to obtain solution A;

[0031] Step 2: Add 0.57g antimony trichloride to 20mL ethanol solution and dissolve to obtain antimony trichloride solution, add 0.06g / mL sodium hydroxide aqueous solution to the antimony trichloride solution to adjust its pH to 8 to obtain a solution B;

[0032] Step 3: Add solution A to solution B and magnetically stir for 30 minutes to obtain solution C;

[0033] Step 4: Put the activated carbon after anodic oxidation for 15 minutes in 20 g / L sodium dihydrogen phosphate aqueous solution at an electrolysis voltage of 3 V for 30 minutes in solution C, transfer solution C and carbon cloth to a polytetrafluoroethylene kettle and Put it in a homogeneous reactor for hydrothermal reaction a...

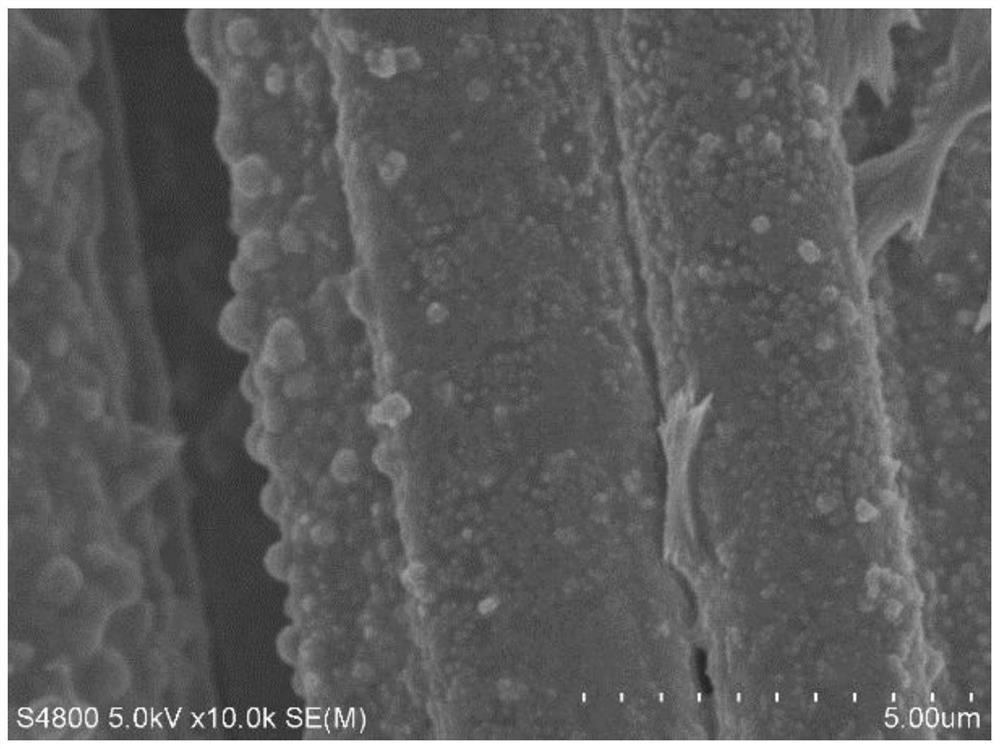

Embodiment 2

[0038] The preparation of a kind of antimony pentoxide / silicon dioxide / carbon cloth flexible material comprises the following steps:

[0039] Step 1: Grind 0.075g of silica particles and add them into 15ml of deionized water for ultrasonic treatment for 1h and dissolve to obtain solution A;

[0040] Step 2: Add 0.3g antimony trichloride to 20mL ethanol solution and dissolve to obtain antimony trichloride solution, add 0.06g / mL sodium hydroxide aqueous solution to the antimony trichloride solution to adjust its pH to 12 to obtain a solution B;

[0041] Step 3: Add solution A to solution B and magnetically stir for 20 minutes to obtain solution C;

[0042] Step 4: In 20g / L sodium dihydrogen phosphate aqueous solution, the activated carbon arrangement was anodized for 8 minutes at an electrolytic voltage of 6V and then immersed in solution C for 60 minutes, and then transferred solution C and carbon cloth to a polytetrafluoroethylene kettle Put it in a homogeneous reactor for h...

Embodiment 3

[0045] The preparation of a kind of antimony pentoxide / silicon dioxide / carbon cloth flexible material comprises the following steps:

[0046] Step 1: Grind 0.15g of silica particles and add them into 25ml of deionized water for ultrasonic treatment for 2h and dissolve to obtain solution A;

[0047] Step 2: Add 1.1 g of antimony trichloride to 40 mL of ethanol solution and dissolve to obtain an antimony trichloride solution, add 0.06 g / mL sodium hydroxide aqueous solution to the antimony trichloride solution to adjust its pH to 9, and obtain a solution B;

[0048] Step 3: Add solution A to solution B and magnetically stir for 60 minutes to obtain solution C;

[0049] Step 4: In 20g / L sodium dihydrogen phosphate aqueous solution, the activated carbon arrangement was anodized for 2 minutes at an electrolytic voltage of 8V and then immersed in solution C for 30 minutes, and then transferred solution C and carbon cloth to a polytetrafluoroethylene kettle Put it in a homogeneous r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com