Patents

Literature

30 results about "Antimony pentaoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified stannic oxide sol, stannic oxide-zirconium oxide composite sol, coating composition and optical element

ActiveUS20060025518A1Bonding properties)Reduce defectsMaterial nanotechnologyTin compoundsOligomerColloidal particle

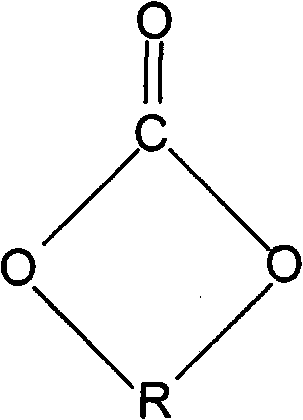

It is to provide a sol useful as a component of a hard coating agent to be applied on the surface of a plastic lens or useful for other applications, and its production process. A sol containing modified metal oxide particles which comprise, as nuclei, colloidal particles (A) being stannic oxide particles or composite particles comprising stannic oxide particles and zirconium oxide particles, containing these oxides in a weight ratio of ZrO2:SnO2 of from 0:1 to 0.50:1 and having particle sizes of from 4 to 50 nm, and as a coating covering the surface of the nuclei, alkylamine-containing Sb2O5 colloidal particles, an oligomer thereof or a mixture thereof (B1), or composite colloidal particles comprising diantimony pentaoxide and silica, an oligomer thereof or a mixture thereof (B2), in a weight ratio of (B) / (A) of from 0.01 to 0.50 based on the weights of the metal oxides, and have particle sizes of from 4.5 to 60 nm. A coating composition containing a silicon-containing substance and the above particles. An optical element covered with the coating composition.

Owner:NISSAN CHEM IND LTD

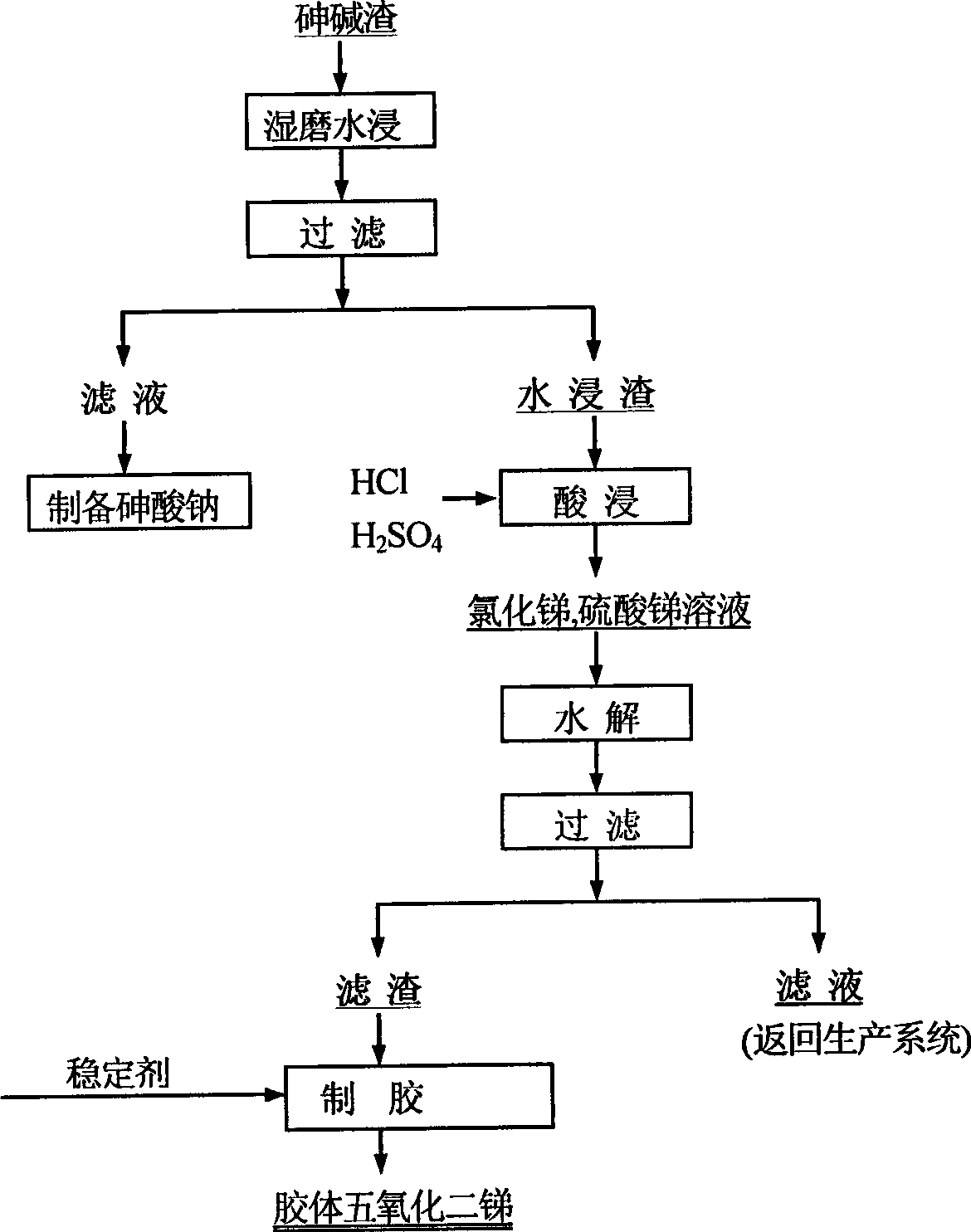

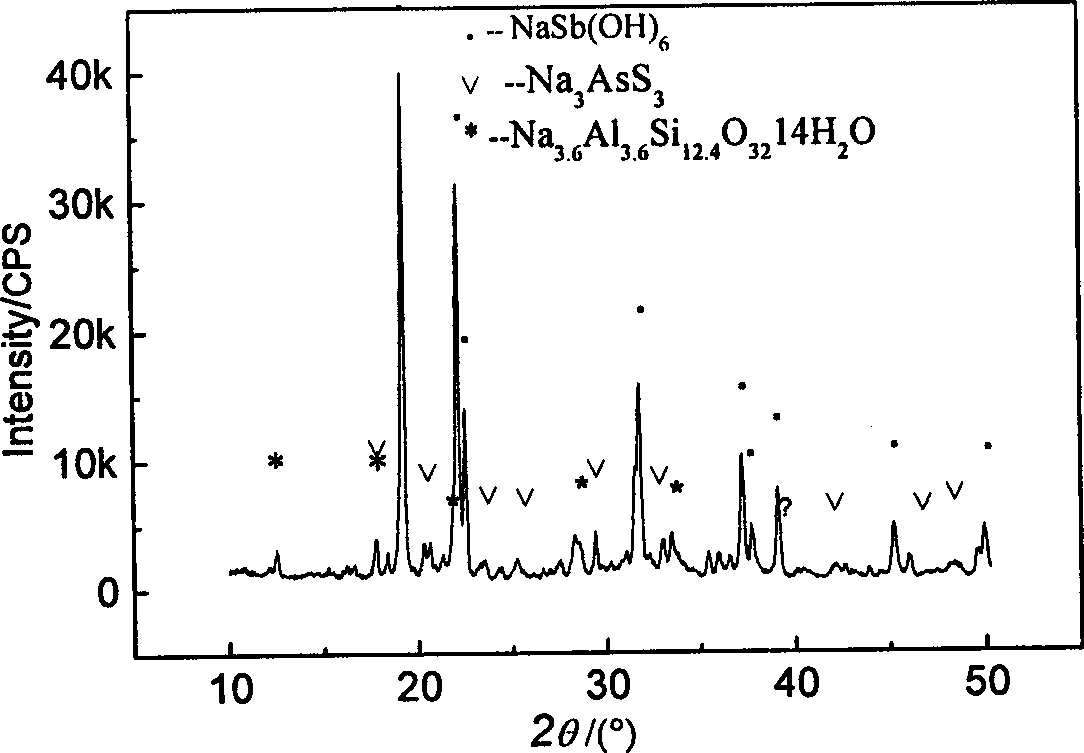

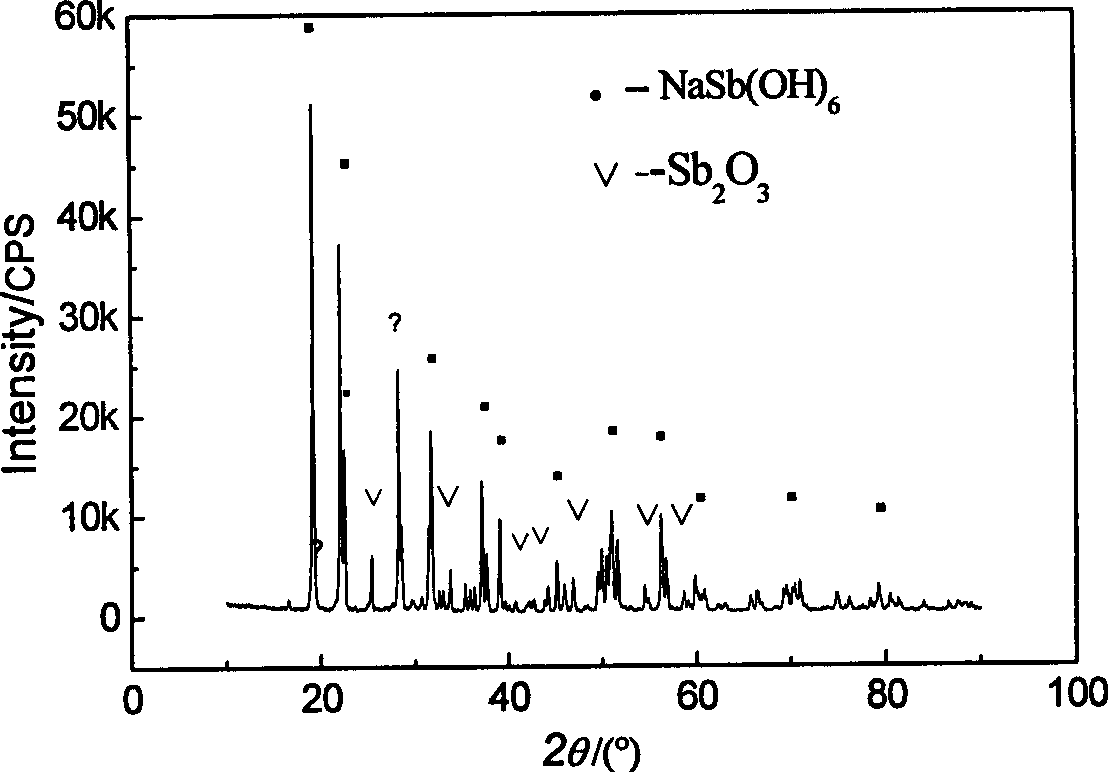

Method for comprehensively processing stibium smelt arsenic alkaline residue and producing colloid antimony peroxide

The invention relates to a method for processing antimony smelting slag, in particular to a method for comprehensively processing antimony smelting arsenic-alkali slag and preparing colloidal antimony pentoxide. The method mainly comprises three processes including water leaching, acid leaching and hydrolysis. The colloidal antimony pentoxide is prepared by an oxidation-hydrolysis method. In the method, the arsenic-alkali slag is subjected to wet processing, antimony resources are recovered while treating the antimony pollution and the colloidal antimony pentoxide is prepared, thereby realizing the recycling of the resources.

Owner:CENT SOUTH UNIV

Tin-antimony oxide conducting film and its production method

InactiveCN1367494AImprove performanceReduced band gapConductive layers on insulating-supportsOxide conductorsTransmittanceChemistry

The present invention relates to a tin-antimony oxide conducting film and its production method. Said film contains (wt%) 80%-96% of tin dioxide and 4%-20% of antimony pentoxide, their grain size diameter is 10-20 nm, and thickness is 80-180 nm. Its production method uses aqueous solution of SnCL4 and SbCL3 ethyl alcohol solution as raw material and includes the following steps: using amkmonia water to make precipitation, using oxalic acid and ammonia water to make back-solvation, concentration, preparing sol-gel, ageing, high-temp. spraying on silex glass for tin-antimony oxide conducting film with high conductivity and light transmittance, and high heat exchange efficiency.

Owner:山东润泰智能电气有限公司

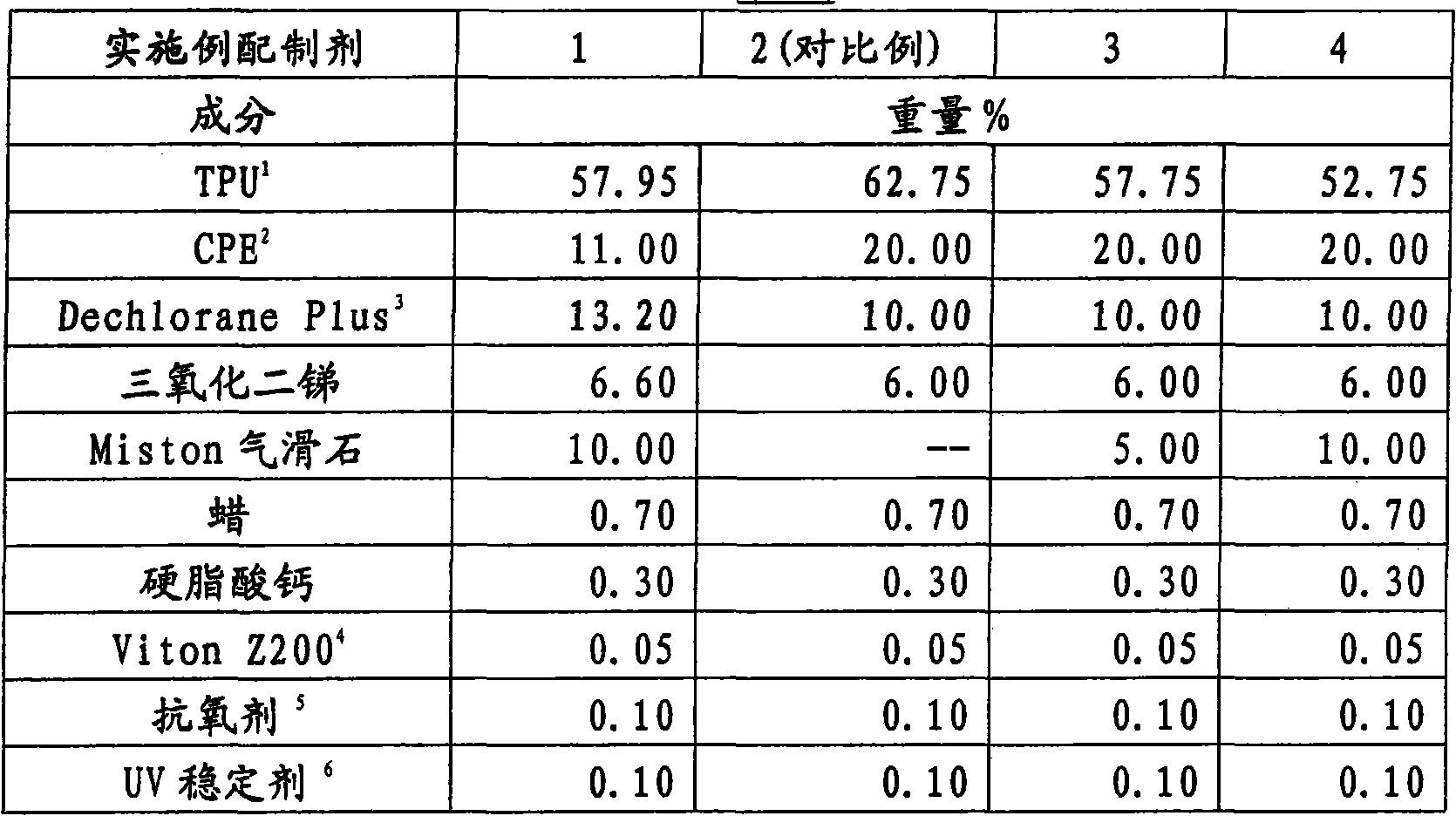

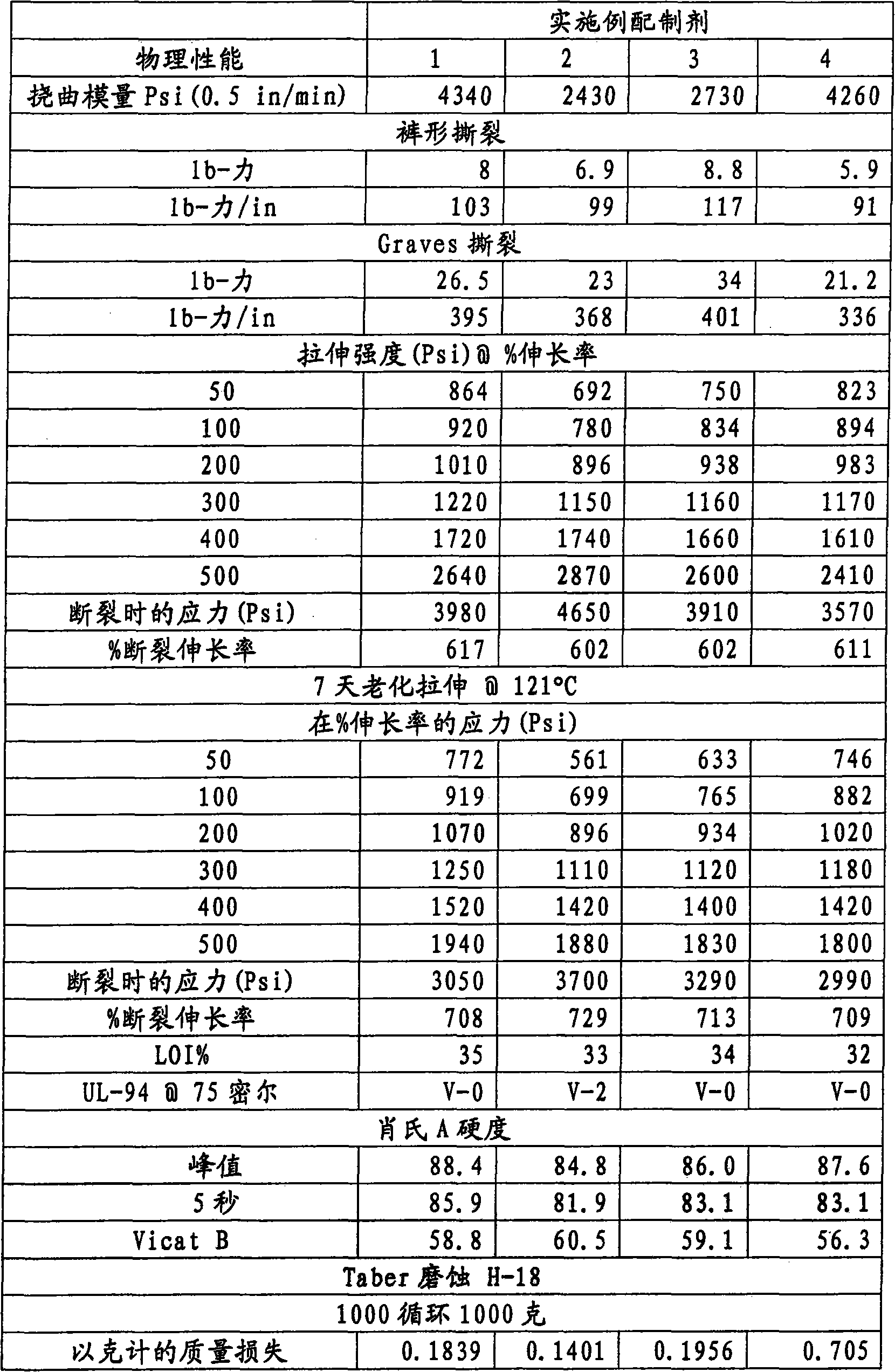

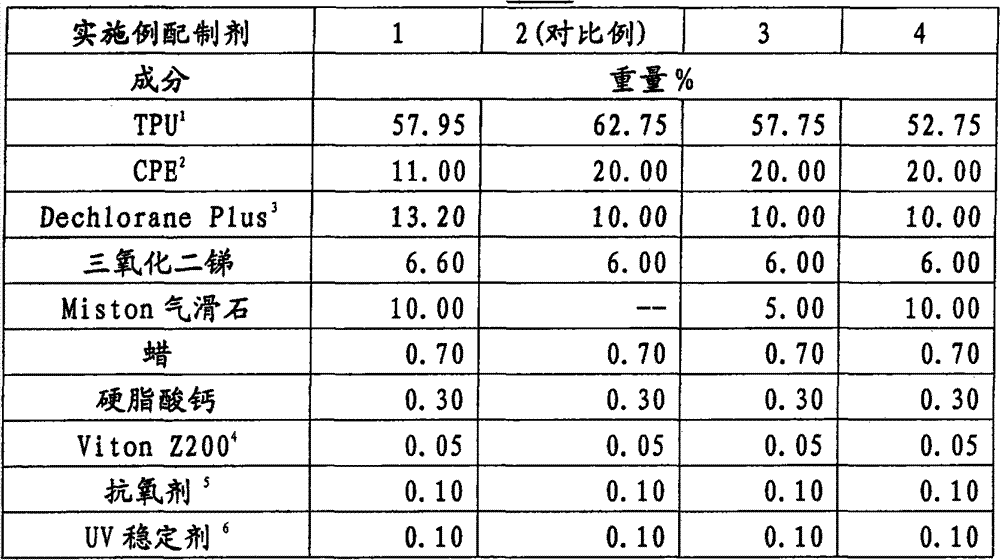

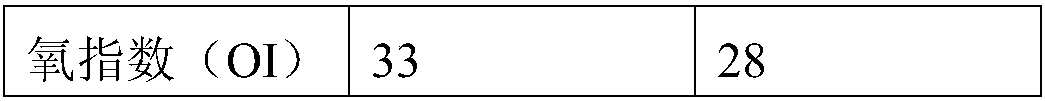

Halogen flame retardant thermoplastic polyurethane

Thermoplastic polyurethane (TPU) formulations are disclosed which comprise a halogenated flame retardant together with an antimony oxide and talc. The formulations exhibit a high LOI (at least 30) and are V-0 rated on the UL-94 test. The halogenated flame retardant can be a chlorinated or brominated compound. The antimony oxide compound is selected from the group consisting of antimony trioxide and antimony pentaoxide. When brominated flame retardants are used, talc is not required, but is preferred to meet the high LOI and V-0 rating. The TPU formulations are useful for wire and cable jacketing applications and for jacketing for fiber optic cables.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Antimony oxide catalyst for preparing quadri-aldehyde by selective oxidation of methane

InactiveCN1621150AGood effectHigh selectivityOrganic chemistryCatalyst activation/preparationPtru catalystPhysical chemistry

The antimony oxide catalyst for oxidizing methane selectively to prepare formaldehyde has antimony trioxide, antimony tetraoxide and antimony pentoxide as catalyst, which may be loaded on silica. The catalyst, when used in the selective methane oxidizing reaction with molecular oxygen as oxidant, can reach formaldehyde selectivity of 24.8 % at 600 deg.c or 17.6 % at 650 deg.c. The silica carried catalyst can reach formaldehyde selectivity of 41 % at 600 deg.c or 18 % at 650 deg.c, and higher formaldehyde yield at 650 deg.c than at 600 deg.c.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Use of nanomaterials in secondary electrical insulation coatings

ActiveUS20070087116A1Improve electrical insulation resistance and corrosion protectionMaterial nanotechnologySpecial tyresInorganic materialsSilicon dioxide

Use of the barrier property effect of nanomaterials to improve the electrical insulation resistance, corrosion protection and bond strength properties of electromagnetic devices. The beneficial effects are realized with nanomaterial loadings of 1-20%, and preferably between 1-5%, parts by weight of coating resins. Nanomaterials include, but are not limited to, silica, alumina, zirconia, and antimony pentoxide, which are dispersed either directly into a coating, or pre-dispersed in a carrier appropriate to the solvent of the resin system. Resulting formulations benefit from the fact anti-settling agents need not be incorporated into the resin to keep the inorganic material suspended. Also, the rheology of the resin system is not significantly altered which would otherwise affect processing of the resins for their intended applications.

Owner:ELANTAS PDG

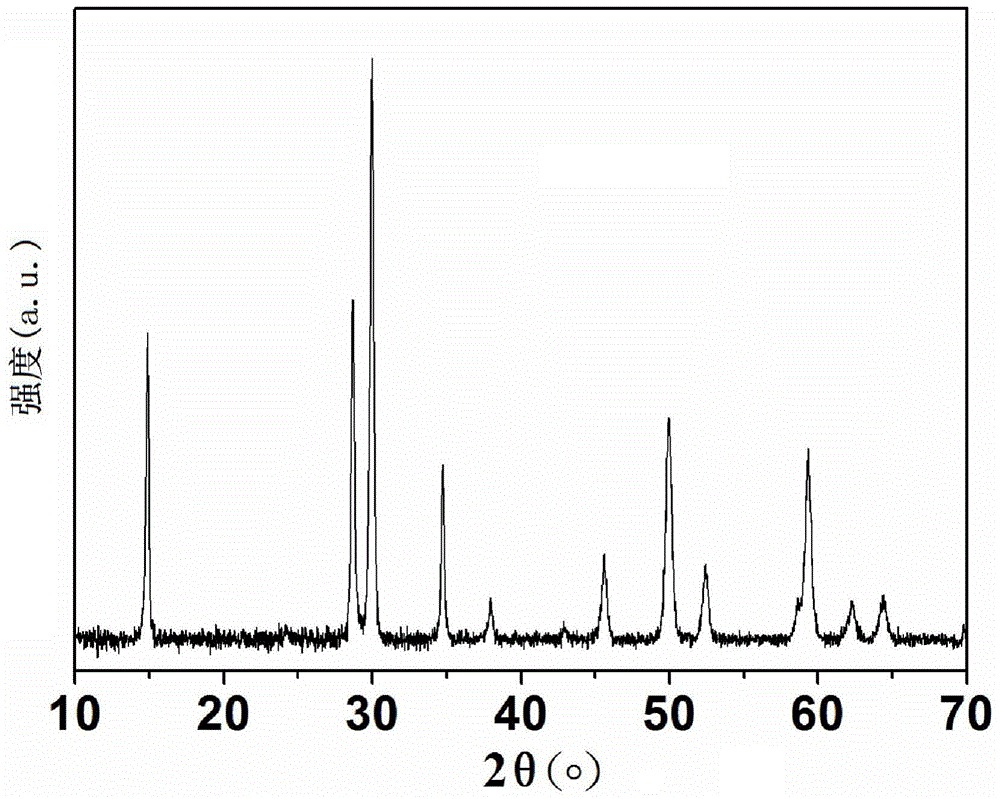

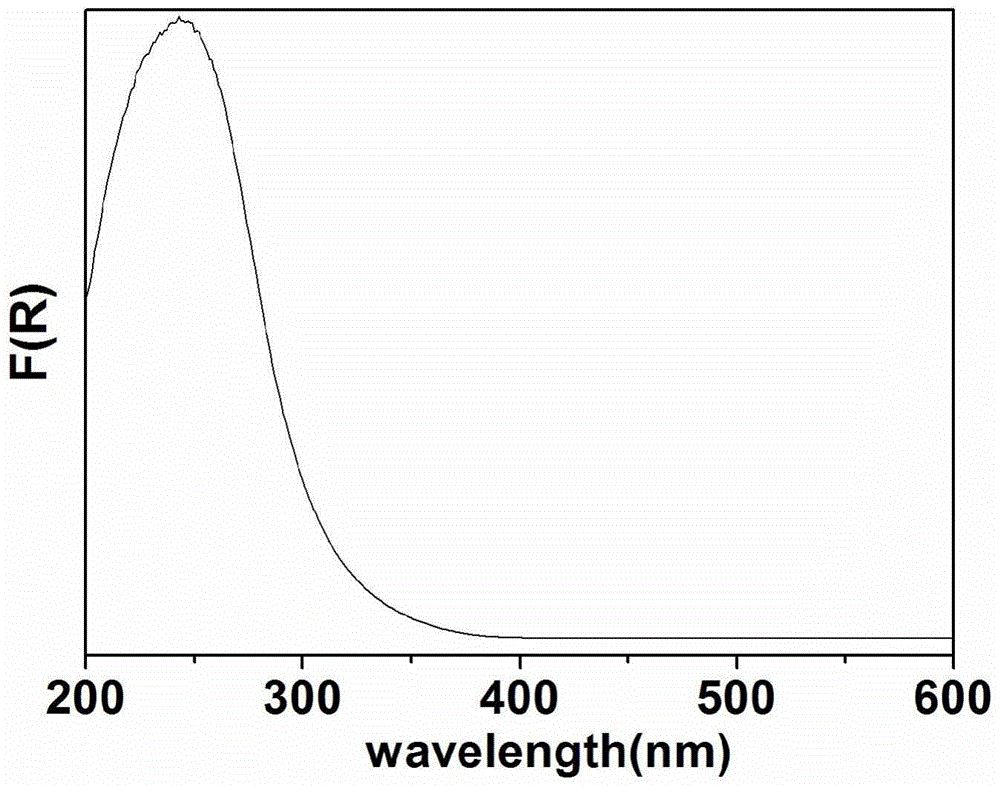

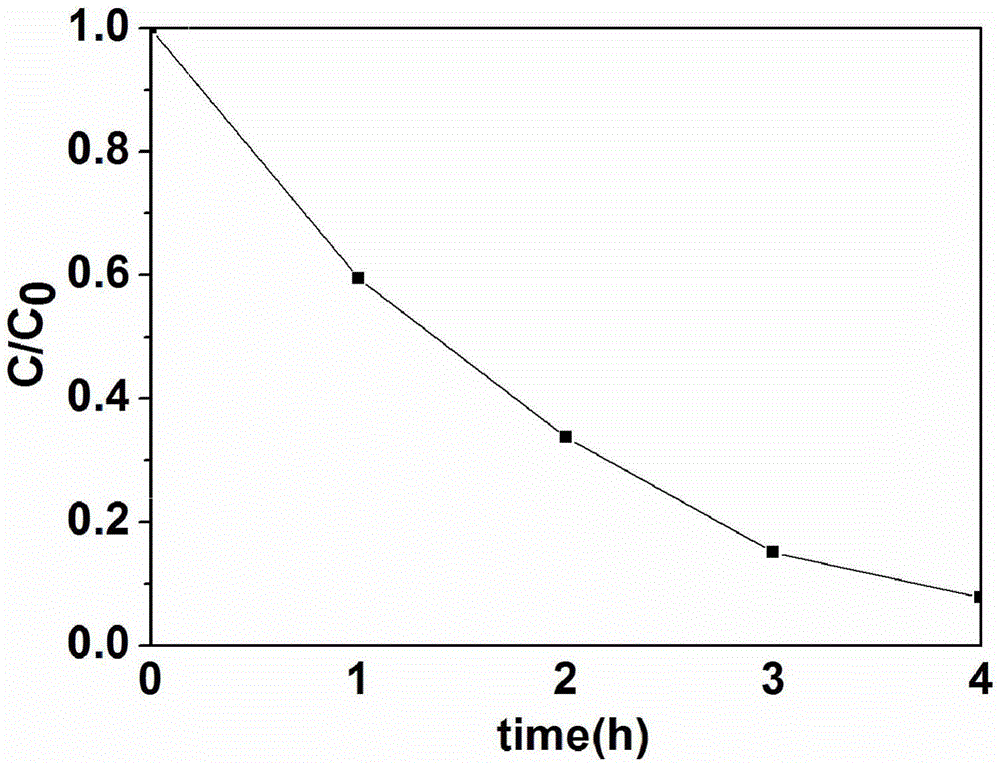

Catalyst for degrading antibiotics in water through photocatalysis as well as preparation method and application of catalyst

ActiveCN104607175ASimple processEasy to controlWater/sewage treatment by irradiationWater contaminantsPtru catalystEthylic acid

The invention discloses a catalyst for degrading antibiotics in water through photocatalysis as well as a preparation method and an application of the catalyst. The preparation method comprises steps as follows: 1), preparation of a nano-powder precursor solution : strontium acetate, antimony pentoxide and 65-75 ml of deionized water are stirred and mixed at the room temperature, the mole ratio of strontium acetate to antimony pentoxide is (1.35-2) :1, the PH is adjusted to 1-5 through 2-6 mol / L of nitric acid, and the nano-powder precursor solution is obtained; (2), preparation of nano-powder under the hydrothermal condition: the nano-powder precursor solution is placed in a 100 ml of high-pressure reaction kettle, is heated to the temperature of 100-200 DEG C at the speed of 1-5 DEG C / min, has a hydrothermal reaction for 6-48 h, is naturally cooled to the room temperature after the reaction ends, and then is taken out, a product is cleaned for 3-5 times with deionized water and absolute ethyl alcohol and put in a drying box to be dried at the temperature of 60-80 DEG C, and a photocatalyst is obtained. The photocatalyst prepared with the preparation method and used for degrading antibiotics in water through photocatalysis can be used for photocatalysis treatment on antibiotics in sewage, and the degradation rate is higher than 89%.

Owner:FUJIAN NORMAL UNIV

Sound insulation and adsorption material for indoor decoration and preparation method thereof

The invention discloses a sound insulation and adsorption material for indoor decoration and a preparation method thereof. The method includes: firstly preparing modified montmorillonite; then taking 25-35 parts of modified montmorillonite, 40-65 parts of a molecular sieve, 15-28 parts of D-mannitol and 38-45 parts of a water soluble polyurethane emulsion, and adding them into a reactor to carry out stirring reaction; then grinding 10-15 parts of ascharite, 8-18 parts of anatase and 4-10 parts of zirconium silicate, then adding the grinding product into the reactor to conduct further stirring; adding 5-10 parts of a carboxymethyl cellulose ammonium salt, 4-8 parts of antimony pentoxide sol and 8-15 parts of a silane coupling agent into the reactor in order, heating the reaction liquid to 80-120DEG C, and carrying out reaction under continuous stirring; and finally adding the mixture into a double-screw extruder to conduct extrusion molding, thus obtaining the sound insulation and adsorption material. The sound insulation and adsorption material provided by the invention has good adsorption performance and sound insulation effect at the same time, and can reach the purposes of purifying indoor air and obstructing noise.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Preparation method of antimony pentoxide composite powder

InactiveCN104355333AImprove stabilityImprove flame retardant performanceAntimony oxides/hydroxides/oxyacidsPhosphateCreatinol phosphate

The invention relates to a preparation method of an antimony pentoxide composite powder. The preparation method comprises the following steps: firstly, antimony trioxide is taken for refining; then the refined antimony trioxide dry powder is added into water, then creatinol-o-phosphate as a stabilizer and oxydol are added for oxidation reflux reaction, after the reaction, a reacting liquid is taken for dialysis for 2 to 3 times, redundant creation o-phosphate is removed, and an antimony pentoxide hydrosol is prepared; finally, the prepared antimony pentoxide hydrosol is added with zeolite powder, the mixture is stirred and then left to stand, precipitate is obtained through centrifugation, and the precipitate is filtered and dried so as to obtain the antimony pentoxide composite powder. The preparation method provided by the invention uses the creatinol-o-phosphate as the stabilizer, and the creatinol-o-phosphate contains a plurality of hydroxies and two inflaming retarding elements N and P, so that the stabilizing effect is good, the flame-retardant effect of the colloid of antimony pentoxide is improved, a zeolite powder is adopted for adsorbing the colloid of antimony pentoxide, so as to prepare the antimony pentoxide-zeolite powder composite powder, during the preparing process, the problem of much loss of antimony pentoxide dry powder during the drying process caused by relatively fine antimony pentoxide dry powder can be solved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Substrate with hard coat film and coating solution for forming hard coat film comprising core-shell composite oxide surface-treated with an organic silicon compound

ActiveUS8748001B2Improve stabilityEasily adjusted in refractive indexMaterial nanotechnologyMixing methodsRefractive indexSilicon dioxide

Modified zirconia fine particles which are stable in an acidic region as well as in an alkaline region, and which may be readily adjusted in refractive index in a predetermined range are disclosed. Also disclosed is a substrate with a hard coat film excellent in adhesiveness with the substrate, abrasion resistance, scratch strength, pencil hardness and the like without interference fringes and a coating solution which may form the hard coat film. The substrate with a hard coat film is composed of composite oxide particles formed on at least one surface of the substrate and a matrix component, wherein the composite oxide particles are composite oxide particles having a core-shell structure composed of a core formed from zirconium oxide and a shell formed from antimony pentoxide and / or silica.

Owner:JGC CATALYSTS & CHEM LTD

High strength multifunctional plastic stool

The invention discloses a high strength multifunctional plastic stool, which includes: a square stool panel and four stool panel supporting legs that together form an internal space. The plastic stool also includes a flexible storage net bag. The square stool panel and the stool panel supporting legs are an integral plastic structure, which comprises the following components by weight: 20-30 parts of PVC plastic, 3-5 parts of ethylene bis lauramide, 20-30 parts of HDPE plastic, 1-5 parts of glycidyl ether epoxy resin, 2-5 parts of lead stearate, 1-10 parts of triethylene-diamine, 30-35 parts of HIPS plastic, 1-3 parts of calcium carbide, 5-8 parts of a coupling agent, 1-4 parts of dicumyl peroxide, 5-10 parts of aramid fiber, 2-5 parts of benzophenone, 7-10 parts of polysulfide rubber, 30-40 parts of PMMA plastic, and 1-3 parts of antimony pentaoxide. In the way, the stool provided by the invention is additionally provided with the net bag for placing articles. In addition, the plastic stool has high strength and great carrying capacity.

Owner:陈凯

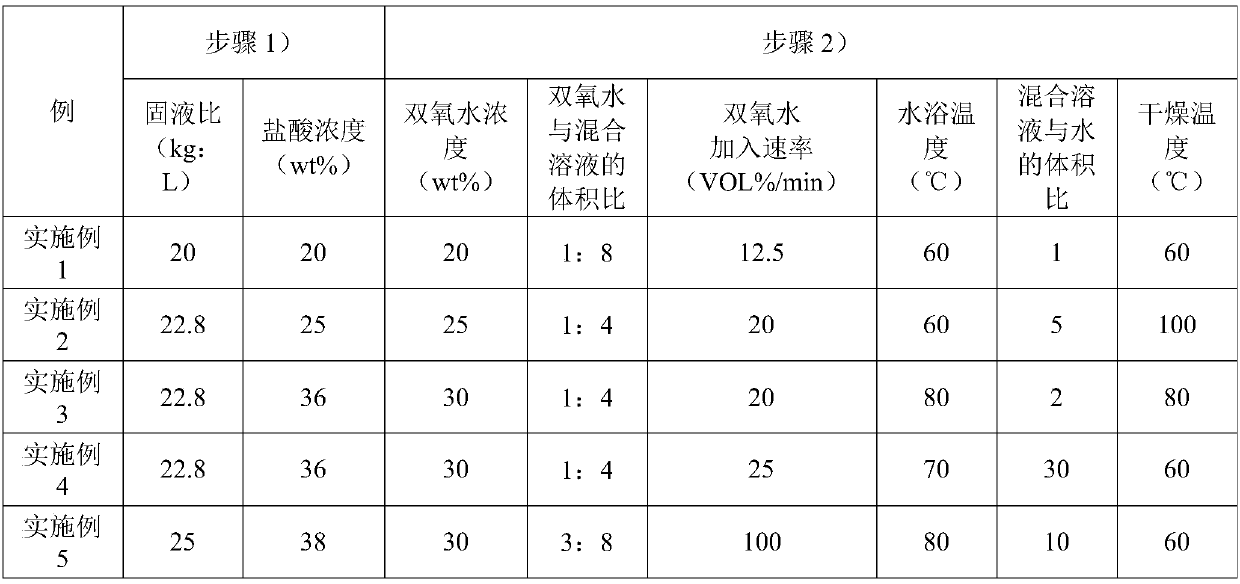

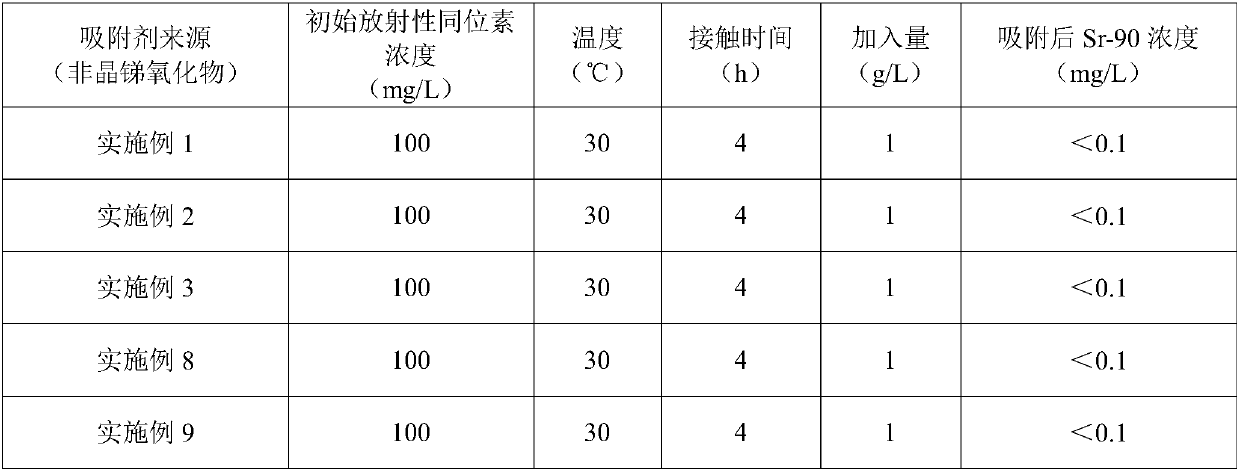

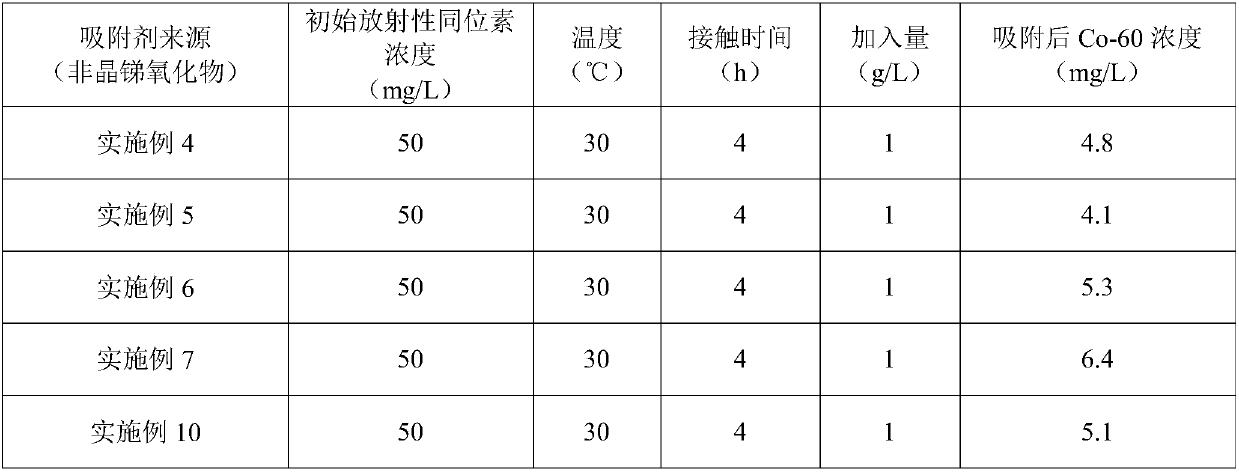

Amorphous antimony oxide for adsorbing radioactive strontium-90 and cobalt-60 and preparation method of amorphous antimony oxide

PendingCN109621884ALarge specific surface areaViolent explosive hydrolysis reactionOther chemical processesAlkali metal oxides/hydroxidesWater bathsSorbent

The invention relates to the field of radioactive element wastewater treatment, and provides an amorphous antimony oxide for adsorbing radioactive Sr-90 and Co-60 and a preparation method of the amorphous antimony oxide in order to solve the problems that an existing organic ion exchange agent has a poor effect and shorter service life when being used for treating low-concentration nuclear radioactive wastewater, and an antimony pentoxide adsorbent prepared in the prior art has the smaller adsorption capacity for Sr-90. The preparation method comprises the following steps that 1) antimony butter and hydrochloric acid are taken as raw materials, weighed and mixed to obtain a mixed solution; 2) the mixed solution is oxidized in a water bath condition and then is mixed and hydrolyzed with a large amount of water, filtering separation is carried out to obtain a hydrolysis product, and the amorphous antimony oxide for adsorbing the radioactive Sr-90 and Co-60 is obtained after drying. The amorphous antimony oxide for adsorbing the radioactive Sr-90 and Co-60 and the preparation method of the amorphous antimony oxide have the advantages that the preparation method is concise and efficient, and a part of raw materials can be recycled; the prepared amorphous antimony oxide has huge specific surface area and a disordered structure, and has a very strong adsorbing effect on Sr-90, Co-60and other radioactive isotopes.

Owner:ZHEJIANG UNIV OF TECH

Polyester, production method thereof, fibers therefrom and catalyst for polymerization of polyester

InactiveUS20070093637A1Controlled crystallization rateReduce in quantityMonocomponent polyesters artificial filamentPolyesterFiber

There are provided a polyester with a controlled crystallization rate which forms fibers stably even in high-speed spinning in the present invention. There are also provided a polyester obtained in the presence of an antimony catalyst comprising: (i) diantimony trioxide, and (ii) 1 to 10 wt % of diantimony tetraoxide and / or diantimony pentaoxide based on diantimony trioxide, a production method therefor, fibers formed therefrom, and a catalyst for polymerization of the polyester.

Owner:TEJIN FIBERS LTD

Halogen flame retardant thermoplastic polyurethane

Thermoplastic polyurethane (TPU) formulations are disclosed which comprise a halogenated flame retardant together with an antimony oxide and talc. The formulations exhibit a high LOI (at least 30) and are V-0 rated on the UL-94 test. The halogenated flame retardant can be a chlorinated or brominated compound. The antimony oxide compound is selected from the group consisting of antimony trioxide and antimony pentaoxide. When brominated flame retardants are used, talc is not required, but is preferred to meet the high LOI and V-0 rating. The TPU formulations are useful for wire and cable jacketing applications and for jacketing for fiber optic cables.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Preparation method of antimony pentoxide colloid for flame retardance of textile fabric

PendingCN113209914AGood dispersionExcellent light projectionHeat resistant fibresSol preparationPotassium ionsDistilled water

The invention discloses a preparation method of antimony pentoxide colloid for flame retardance of a textile fabric, wherein the preparation method comprises the steps: uniformly mixing antimony trioxide powder and peroxide, adding into a container, dropwise adding distilled water, heating to 90-100 DEG C after dropwise adding, and condensing, refluxing and stirring for 1-2 hours to obtain antimony pentoxide sol; S2, heating, evaporating and concentrating the antimony pentoxide sol in the step S1 under a water bath condition of 95-100 DEG C until the water content is 40-45% to obtain antimony pentoxide powder, dispersing the antimony pentoxide powder in an aqueous solution of sodium dodecyl benzene sulfonate and benzylamine, stirring at room temperature for 2-5 hours, and performing suction filtration to obtain modified antimony pentoxide sol; and removing sodium ions or potassium ions in the antimony pentoxide sol in the step S2 by using cation exchange resin at 30-35 DEG C; and S3, heating the antimony pentoxide sol obtained in the step S3 at 95-98 DEG C, evaporating, concentrating to 46-48%, adding lactic acid into the concentrated sol, stirring for 30-60 minutes, heating in a water bath at 50-70 DEG C, dropwise adding an ethanol solution, and stirring for 1-2 hours after dropwise adding to obtain the antimony pentoxide sol.

Owner:海宁恒爱新材料有限公司

Preparation process of bimetallic passivator

InactiveCN110841723AAvoid harmHigh antimony contentCatalytic crackingCatalyst protectionOrganic acidPtru catalyst

The invention discloses a preparation process of a bimetallic passivator, and belongs to the technical field of petrochemical engineering. The preparation process comprises the following three steps in sequence: preparation of a single antimony passivator, preparation of a single cerium passivator and preparation of a composite passivator, wherein an organic acid and an organic amine are reacted at a certain ratio to further form a chelate with antimony trioxide and cerium carbonate, and a water-soluble passivator product is formed. Compared with a traditional passivator process, hydrogen peroxide is not used as a raw material, so that the risk in the production process is reduced, and harm caused by contact of workers with hydrogen peroxide is avoided. Compared with the prior art, the process has the advantages that the antimony trioxide structure is reserved, antimony pentoxide is formed without hydrogen peroxide oxidation, compared with antimony pentoxide, the content of antimony inantimony trioxide molecules is higher, and when unit mass of antimony oxide is deposited on a catalyst, the content of antimony on the surface of the catalyst is higher, and the antimony hanging rateis higher.

Owner:宿迁明江化工股份有限公司

Raw material formula for sunscreen heat-insulating plastic woven bag

InactiveCN113234282ANot easy to ageExtended service lifeLow-density polyethyleneDecabromodiphenyl ether

The invention discloses a raw material formula for a sunscreen heat-insulating plastic woven bag. The raw material formula comprises, by weight, 80-120 parts of polypropylene; 40-60 parts of low density polyethylene; 5-8 parts of nano titanium carbonate; 2-5 parts of talcum powder; 2-4 parts of silicon resin; 4-8 parts of filling master batch; 5-7 parts of an ultraviolet light absorber; 0.5-2 parts of nano silicon dioxide; 4-6 parts of a synthetic agent; 1-2 parts of an anti-mildew antibacterial agent; 1-3 parts of an antistatic agent; 8-12 parts of decabromodiphenyl ether; 0.1-0.3 part of a heat and light stabilizer; 2-4 parts of antimony pentoxide; and 4-6 parts of an anti-wear agent. The synthetic agent is prepared from, by weight, 0.3-0.5 part of a generating agent, 0.6-0.8 part of a coupling agent, 0.4-0.6 part of a compatilizer, 0.3-0.5 part of an antioxidant, 0.3-0.6 part of a conditioning agent, 0.3-0.5 part of a reinforcing agent, 0.6-0.8 part of a flocculation agent, 0.6-0.9 part of a plasticizer and 0.3-0.4 part of a terminating agent. The sunscreen heat-insulating plastic woven bag has the advantages of being long in service life, high in sunscreen heat-insulating effect, high in drawing force, not prone to damage and high in wear resistance.

Owner:南塑集团黑龙江包装有限公司

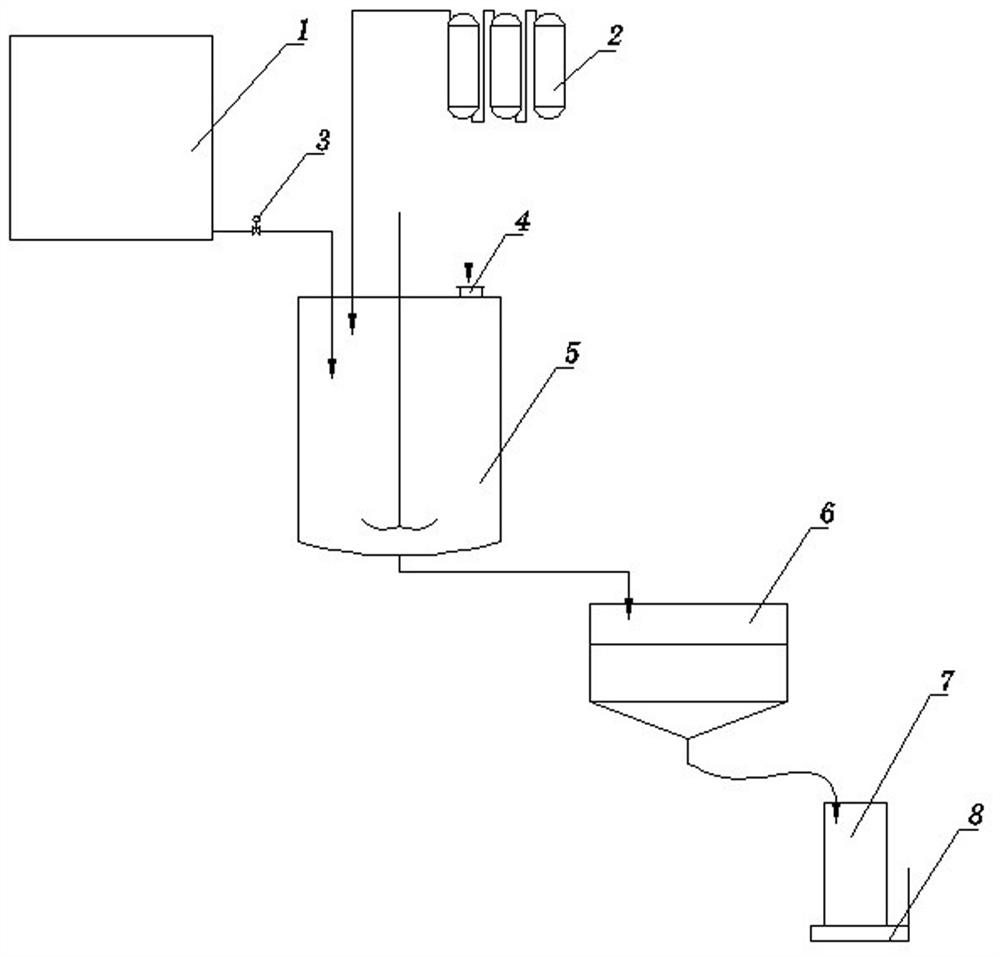

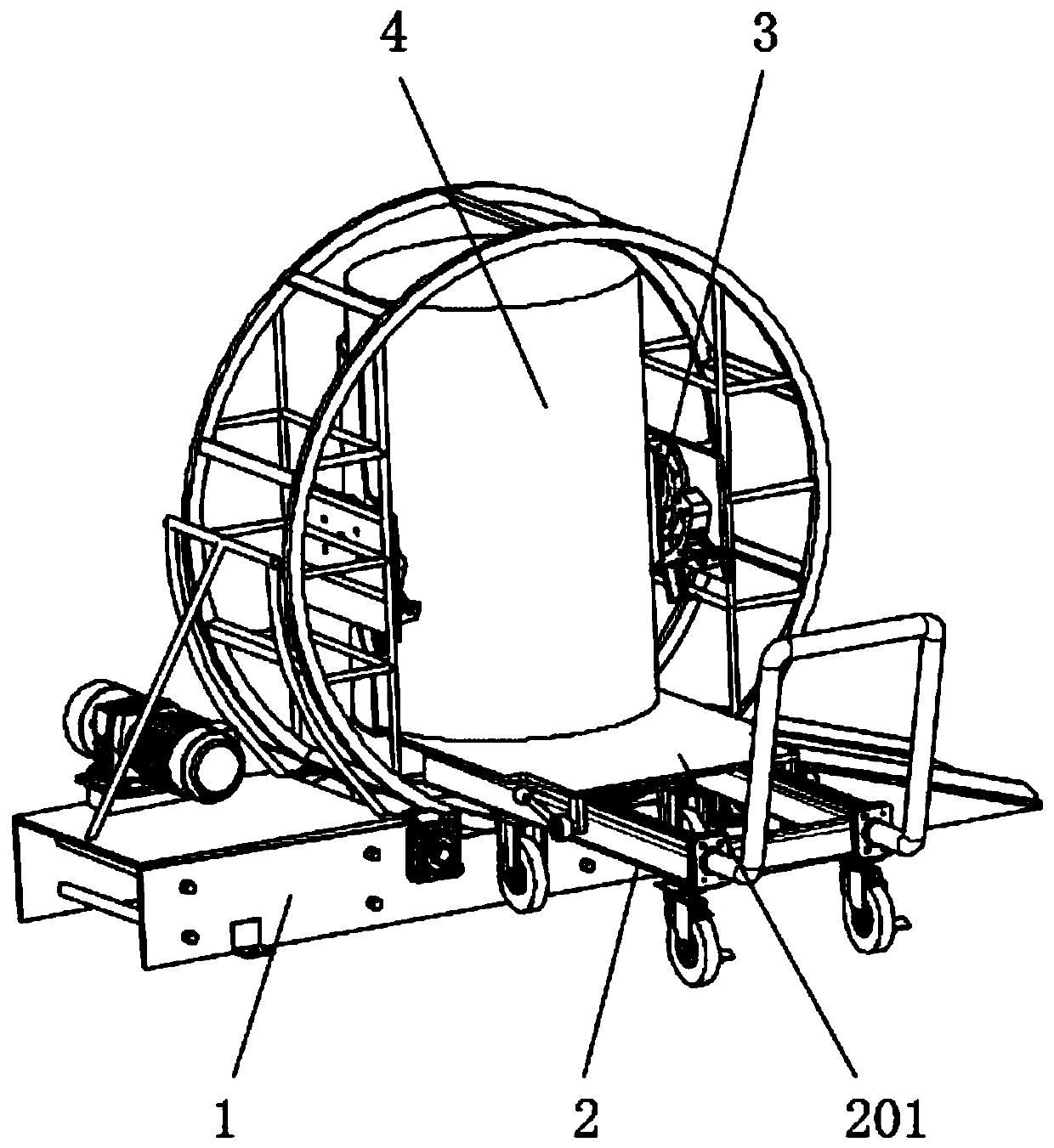

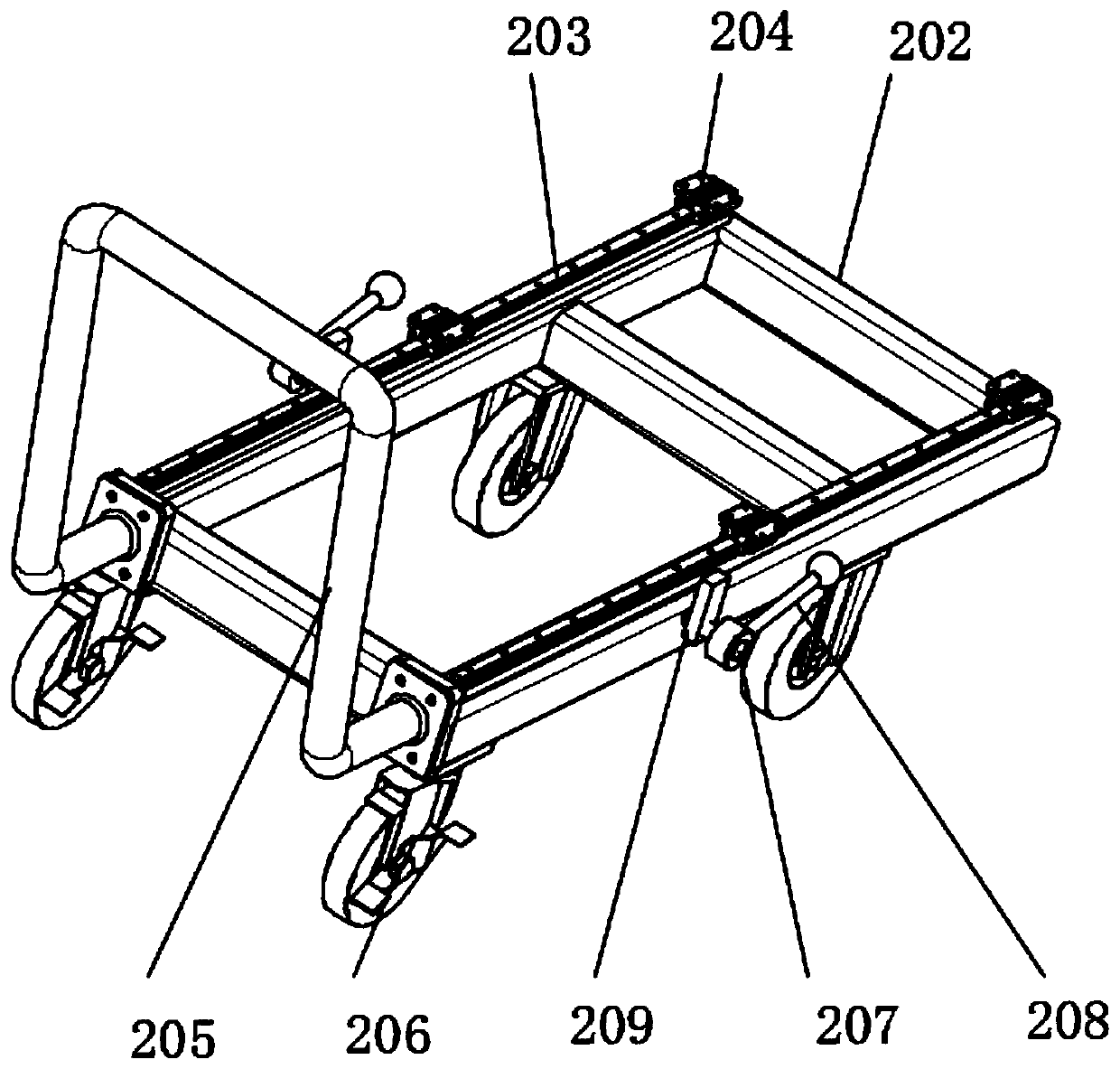

Colloidal antimony pentoxide manufacturing device and method

PendingCN111977687ASimple structureReduce the liquid-solid ratioAntimony oxides/hydroxides/oxyacidsSol preparationHigh concentrationPtru catalyst

The invention discloses a colloidal antimony pentoxide manufacturing device. The colloidal antimony pentoxide manufacturing device comprises a hydrogen peroxide head tank, a microwave reaction kettle,a filtering device and a packaging barrel which are sequentially connected through pipelines from top to bottom, wherein a connecting port of a deionized water device and a material adding port are arranged above the microwave reaction kettle; a hydrogen peroxide flowmeter is arranged on a pipeline between the hydrogen peroxide head tank and the microwave reaction kettle; and a metering device isarranged below the packaging barrel. The invention further discloses a method for manufacturing colloidal antimony pentoxide by using the colloidal antimony pentoxide manufacturing device. The deviceis simple in structure, a catalyst is introduced during reaction, oxidation reaction and concentration are carried out by adopting microwave heating, the liquid-solid ratio of the oxidation reactionis greatly reduced, and the reaction speed is increased; and particularly when high-concentration colloidal antimony pentoxide is produced due to the reduction of the liquid-solid ratio, water needingto be evaporated during concentration can be greatly reduced, so that the energy consumption is greatly reduced. The process time is shortened, and the production efficiency is greatly improved.

Owner:锡矿山闪星锑业有限责任公司

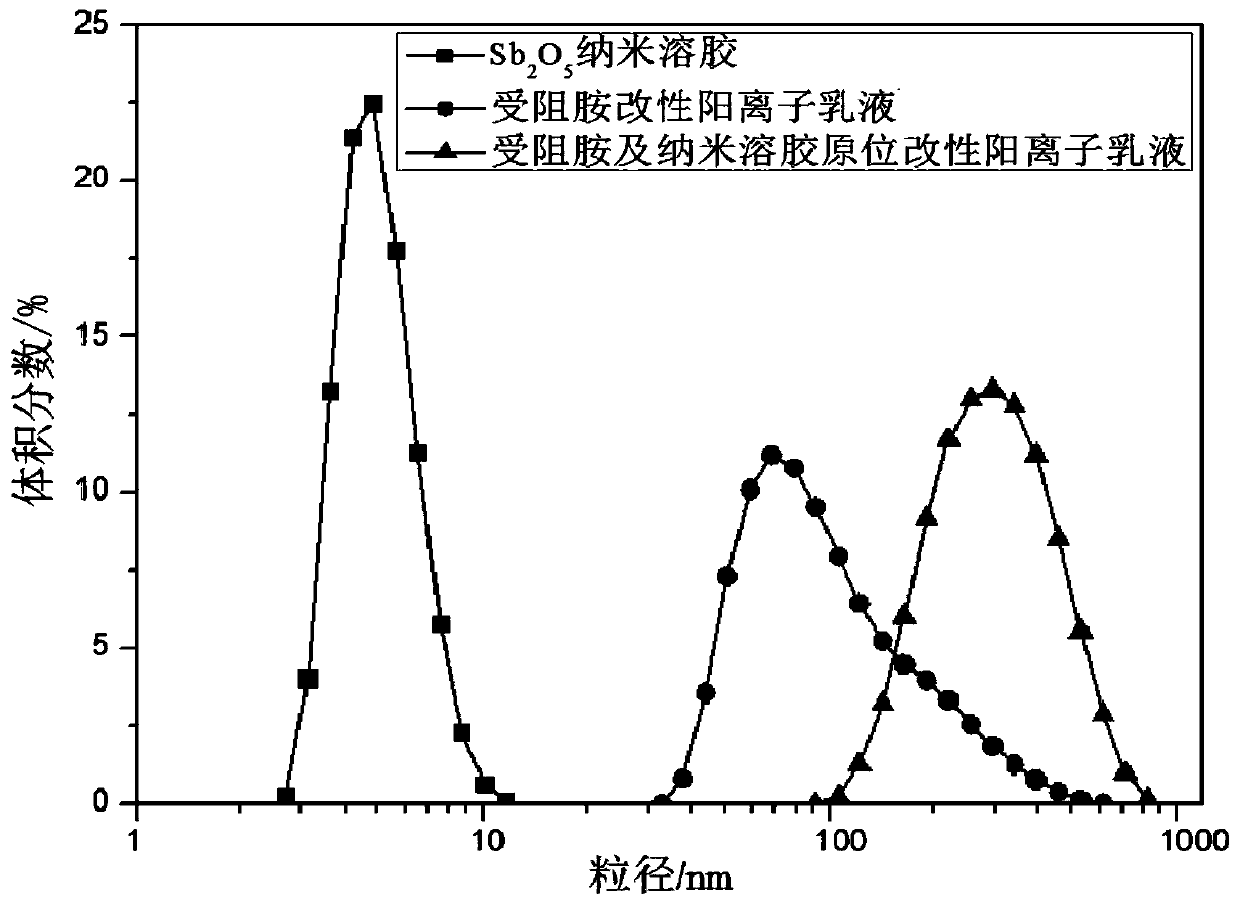

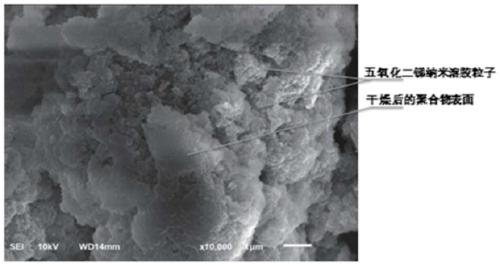

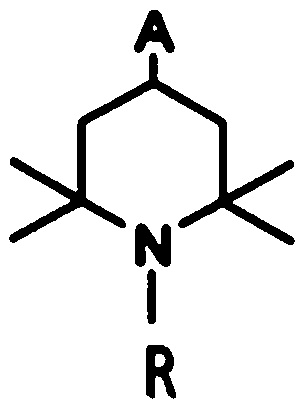

Halogen-free high-efficiency flame-retardant cationic emulsion modified in-situ by nanomaterials and preparation method thereof

ActiveCN108546313BObvious polymerization inhibitionHigh reaction conversion rateAcrylic polymerMaterials science

The invention discloses a nano-material in-situ modified halogen-free efficient flame-retardant cationic emulsion. The nano-material in-situ modified halogen-free efficient flame-retardant cationic emulsion is obtained through subjecting raw materials to cationic in-situ polymerization, wherein based on 100 parts by weight, the raw materials comprises 40-60 parts of water, 25-35 parts of acrylatemonomer, 3-15 parts of antimony pentoxide nano-hydrosol, 0.5-5 parts of hindered amine free radical capturing agent, 0.1-1.5 parts of azo diisobutyl amidine hydrochloride, 0.1-3 parts of emulsifier, 4-7 parts of cationic starch dispersion solution and 0-0.5 parts of silane coupling agent. The invention further discloses a preparation method for the halogen-free efficient flame-retardant cationic emulsion. According to the halogen-free efficient flame-retardant cationic emulsion disclosed by the invention, a flame-retardant system, prepared from antimony pentoxide nano-sol and the hindered amine free radical capturing agent through cooperation, is effectively distributed on the surfaces of or in the acrylic polymer emulsion particles in a nano scale; and the flame-retardant effect is very efficient, and the emulsion is halogen-free and environmentally friendly.

Owner:JIANGSU RUIKANG NEW MATERIAL TECH CO LTD

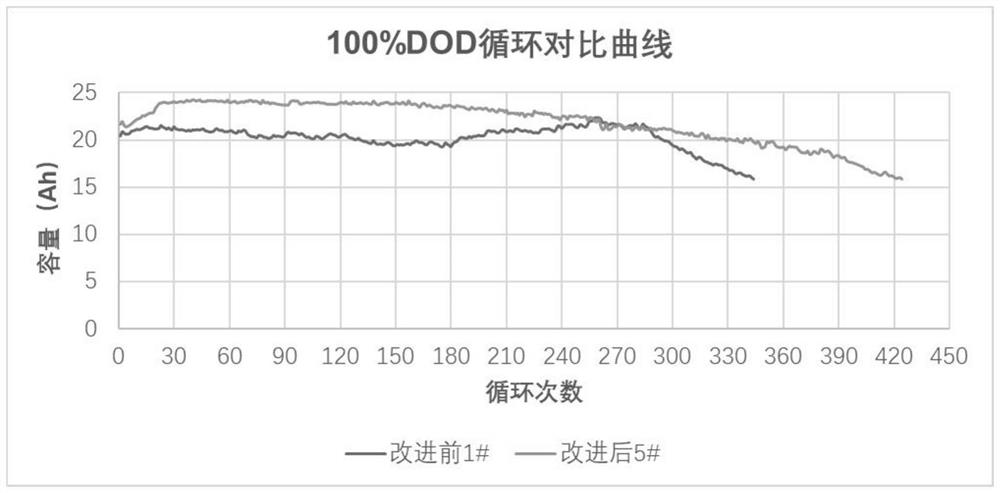

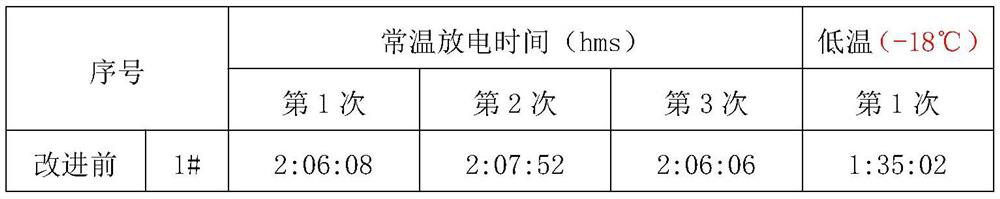

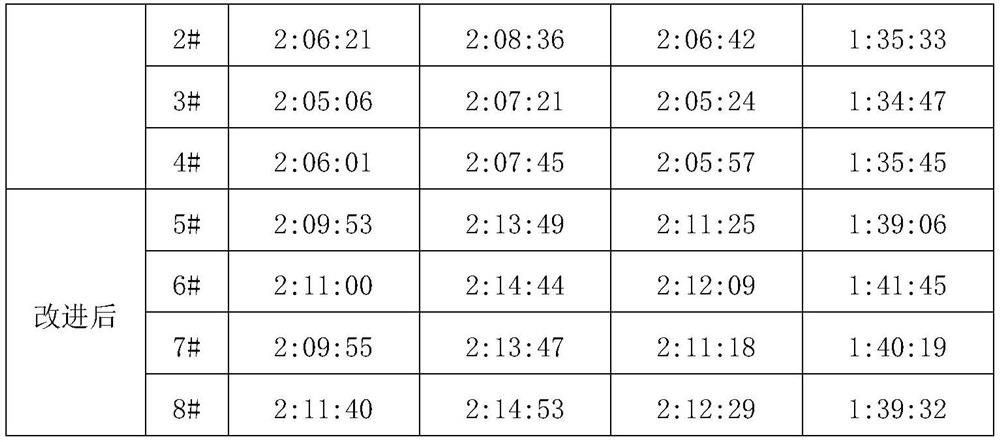

Cyclic lead-acid storage battery positive electrode lead paste formula and preparation method thereof

PendingCN114220966AImprove conductivityNormal and low temperature capacity increaseElectrode manufacturing processesLead-acid accumulatorsFiberElectrical battery

The invention provides a circulating lead-acid storage battery positive electrode lead paste formula. The circulating lead-acid storage battery positive electrode lead paste formula comprises the following components in percentage by mass relative to lead powder: 8-10% of dilute sulfuric acid, 8-12% of deionized water, 0.05-0.12% of short fibers, 0.1-0.4% of colloidal graphite, 0.05-0.12% of stannous mono-sulphate, 0.05-0.12% of antimony pentoxide and the balance of lead powder. The preparation method has the advantages that 1, antimony pentoxide does not generate an inhibiting effect on the generation of tetrabasic lead sulfate; 2, Sb < 5 + > is connected with three hydrated polymer chains in a positive active material, and Sb < 3 + > is only connected with two hydrated polymer chains, so that the proton conductivity among the active materials is enhanced by antimony pentoxide; under the condition that the quality of the active substance is not changed, the normal and low temperature capacity of the battery is improved to a certain extent. And 3, the reaction between dilute sulfuric acid and lead powder is an exothermic reaction, the temperature in the paste mixing process can be increased by increasing the acid adding speed in the manufacturing process, air cooling is started when the temperature reaches 85 DEG C, and the high temperature maintained for a certain time is beneficial to generation of tetrabasic lead sulfate in the lead paste.

Owner:ANHUI LEOCH BATTERY TECH

A kind of lead accumulator that overcomes early capacity fading and preparation method thereof

ActiveCN110364770BPrevent early capacity fadingPromote migrationFinal product manufactureCell electrodesElectrolytic agentElectrical battery

The invention discloses a lead accumulator for overcoming early capacity attenuation of lead-calcium alloy batteries and a preparation method thereof, belonging to the technical field of accumulators. The preparation method comprises: (1) dry mixing antimony trioxide or antimony pentoxide, fiber and lead powder, adding water for wet mixing, adding sulfuric acid solution to form a paste with a specific gravity of 3-3.8; (2) Immersing the lead-calcium alloy grid in the paste, wrapping the paste on its surface to form a transition layer; (3) coating the lead paste on the grid with the transition layer to obtain a green electrode plate; (4 ) curing under the condition of no more than 55° C. to obtain the positive plate; (5) assembling the battery, adding electrolyte, and internalizing to obtain the lead storage battery. In the present invention, a transition layer with high content of antimony is formed on the surface of the lead-calcium alloy grid in advance, and the antimony-containing corrosion layer is more difficult to discharge than the active material, so that the grid-active material interface cannot form a passivation layer, effectively overcoming the early stage of the battery. capacity decay.

Owner:TIANNENG BATTERY GROUP

A kind of preparation method of catalytic cracking double metal passivator

ActiveCN109603923BStable in natureUniversalCatalytic crackingCatalyst protectionOrganic acidAqueous solution

The application belongs to the technical field of refining aids, and in particular relates to a method for preparing a catalytic cracking bimetal passivator, comprising the following steps: mixing water, organic acid, and antimony trioxide in a certain proportion, adding hydrogen peroxide dropwise to the mixed solution In, antimony pentoxide hydrosol was obtained. Add organic amine to antimony pentoxide hydrosol, and then add system stabilizer to the system to obtain antimony-based passivation agent; add lanthanum carbonate, organic acid, and water to antimony-based passivator to obtain stable bimetallic passivation agent agent. The passivating agent prepared according to the invention has stable properties, strong universality, long shelf life and safe production process. The reagents used in the invention are all industrial-grade products, the production cost is reduced, energy is saved, and the invention is suitable for industrial production.

Owner:山东京博众诚清洁能源有限公司

Modified recycled plastic particle with flame retardancy

InactiveCN111454503AImprove flame retardant performanceGood weather resistanceGlass fiberPlasticizer

The invention discloses a modified recycled plastic particle with flame retardance, which comprises the following raw materials in parts by weight, 15-40 parts of polyethylene, 8-25 parts of polycarbonate, 12-30 parts of polycaprolactone, 1-8 parts of hexabromocyclododecane, 2-6 parts of antimonous oxide, 3-5 parts of antimonous oxide, 4-8 parts of nano silicon dioxide, 2-12 parts of glass fiber,8-20 parts of pigment filler, 3-8 parts of coupling agent, 3-8 parts of dispersing agent, 2-6 parts of stabilizer, 4-10 parts of plasticizer, 1-5 parts of antioxidant and 5-10 parts of intumescent flame retardant. According to the preparation method, the intumescent flame retardant and the antioxidant are added into the raw materials to be matched for use, the flame retardance of the modified recycled plastic particles can be improved, the preparation efficiency of the modified recycled plastic particles can be improved through the arranged stirring device, and the mixing degree of the raw materials is improved.

Owner:安徽成龙塑业科技有限公司

A kind of preparation method of low viscosity antimony pentoxide hydrosol

ActiveCN108793250BReduce dosageImprove liquidityAntimony oxides/hydroxides/oxyacidsPhysical chemistryViscosity

The invention provides a preparation method of a low-viscosity antimony pentoxide hydrosol. The method comprises the following steps: (1) after water is heated, adding antimony trioxide for mixing, continuing heating and stirring, and adding hydrogen peroxide for reaction; and (2) concentrating, adding a stabilizer stepwise in the concentration process, immediately cooling after the concentrationis completed, and then adjusting the pH value to obtain the low-viscosity cerium pentoxide hydrosol. The method has the advantages that less stabilizer is used, and the prepared low-viscosity antimonypentoxide hydrosol is clearly milk white, yellowish and lustrous and has good fluidity, wherein the content of antimony pentoxide is 48-54%, the pH value is 6.1-6.8, the viscosity (25 DEG C) is lessthan 15mPa.s, the specific gravity (at room temperature) is 1.751-1.849, good stability is realized, and the direct yield of bismuth pentoxide from hydrosol to organosol is greater than or equal to 98.5%. The preparation method provided by the invention is simple, convenient to operate, low in cost, and environment-friendly.

Owner:锡矿山闪星锑业有限责任公司

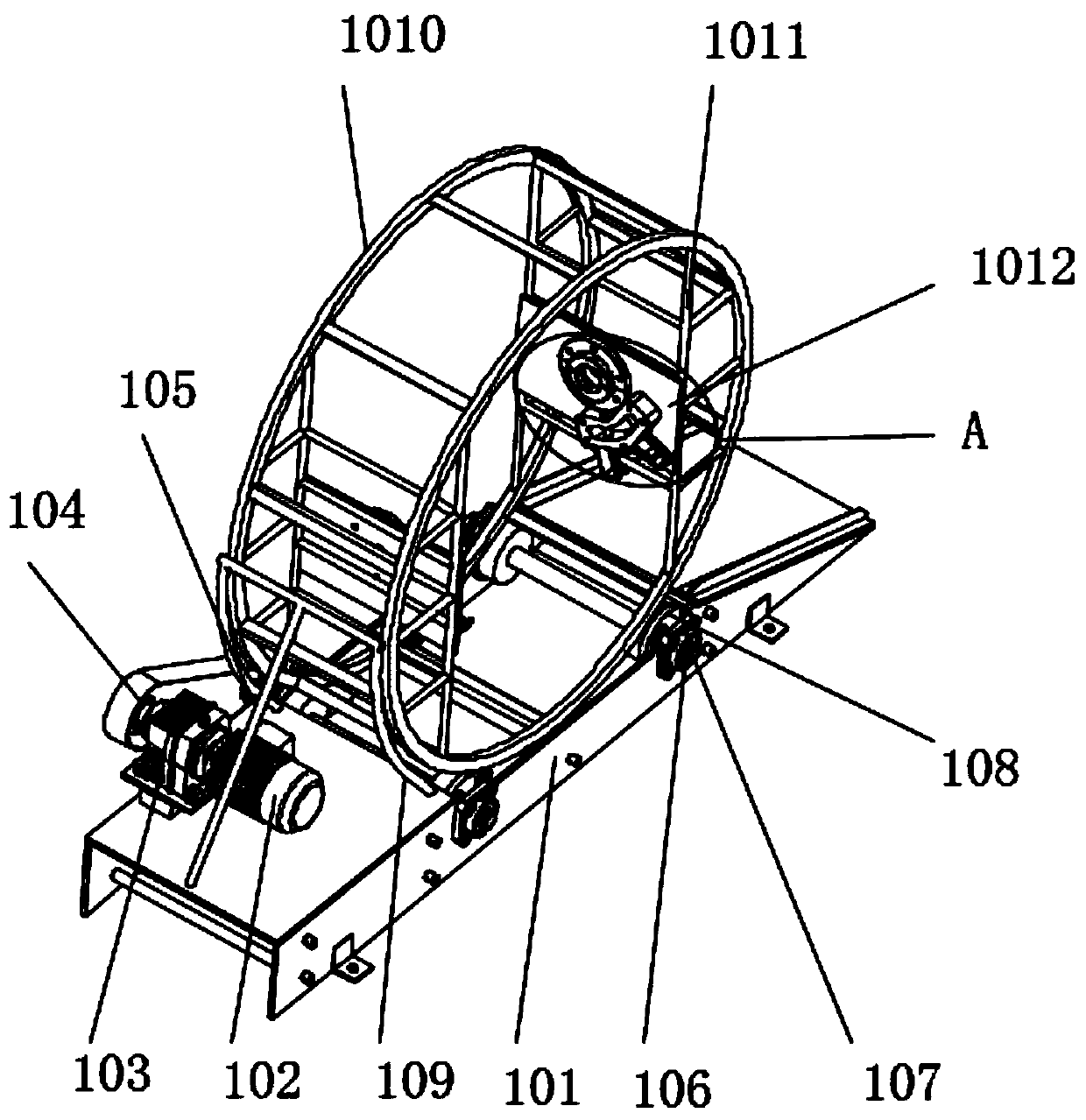

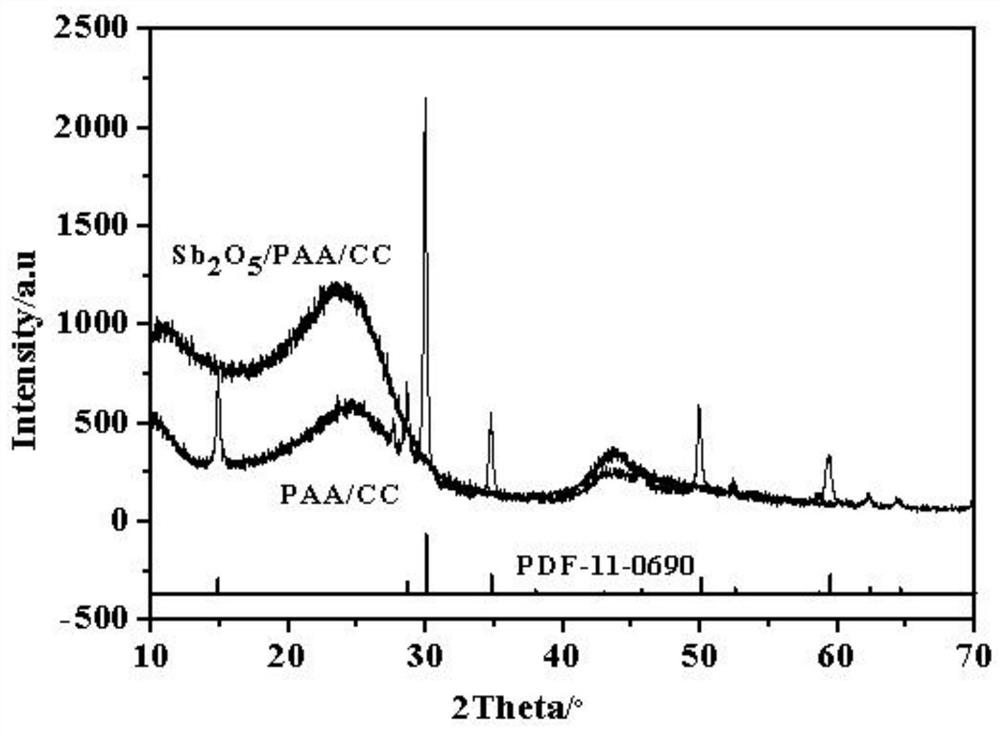

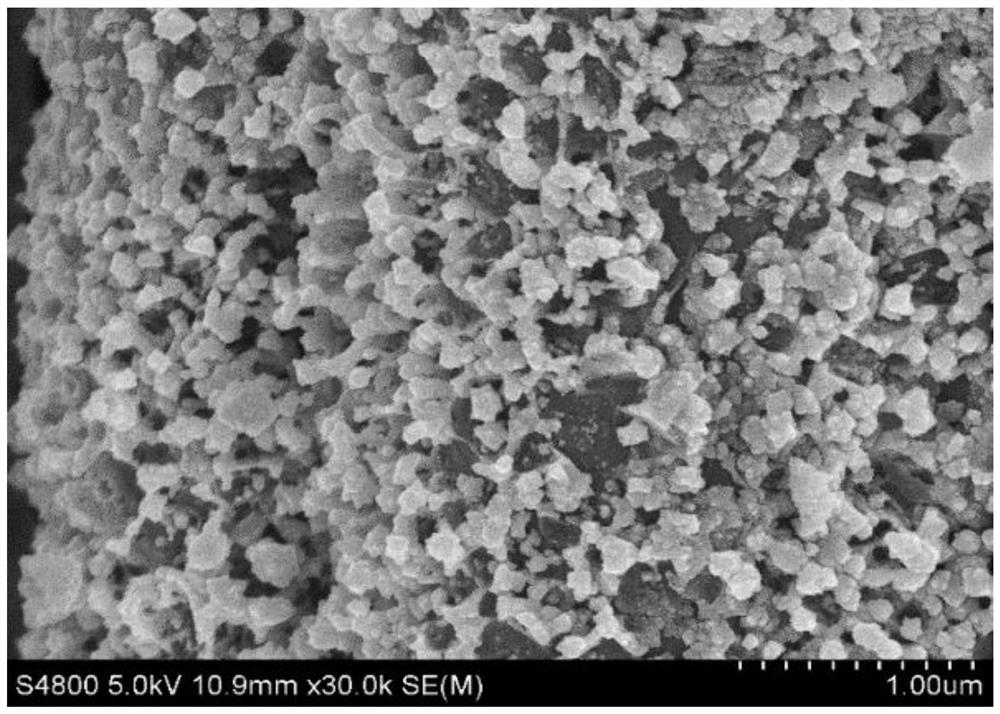

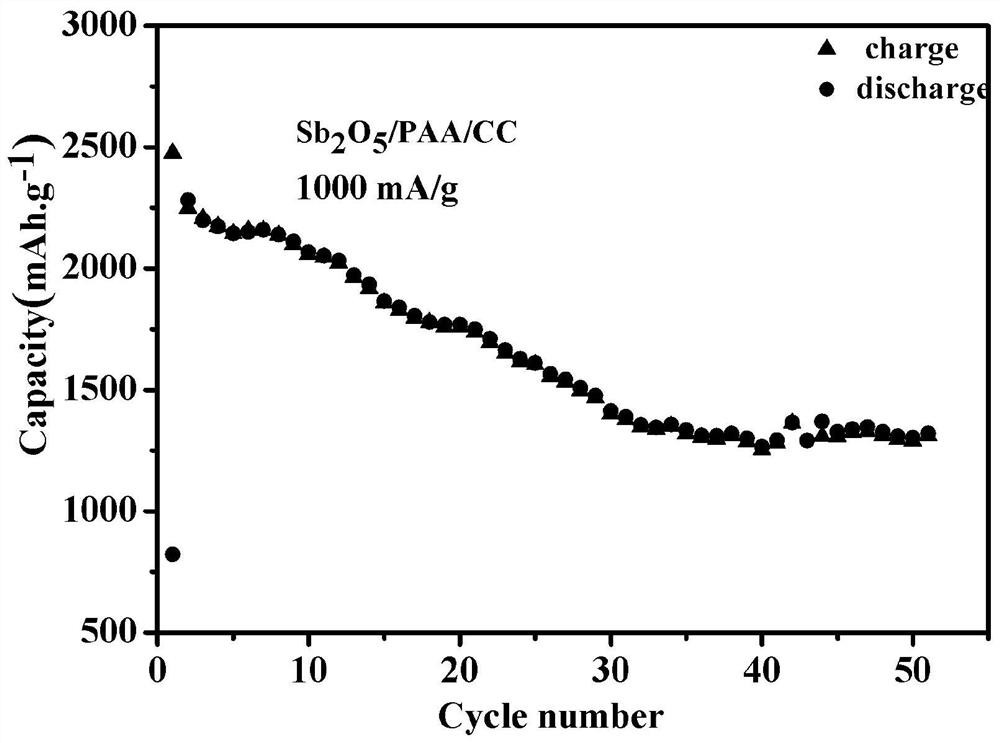

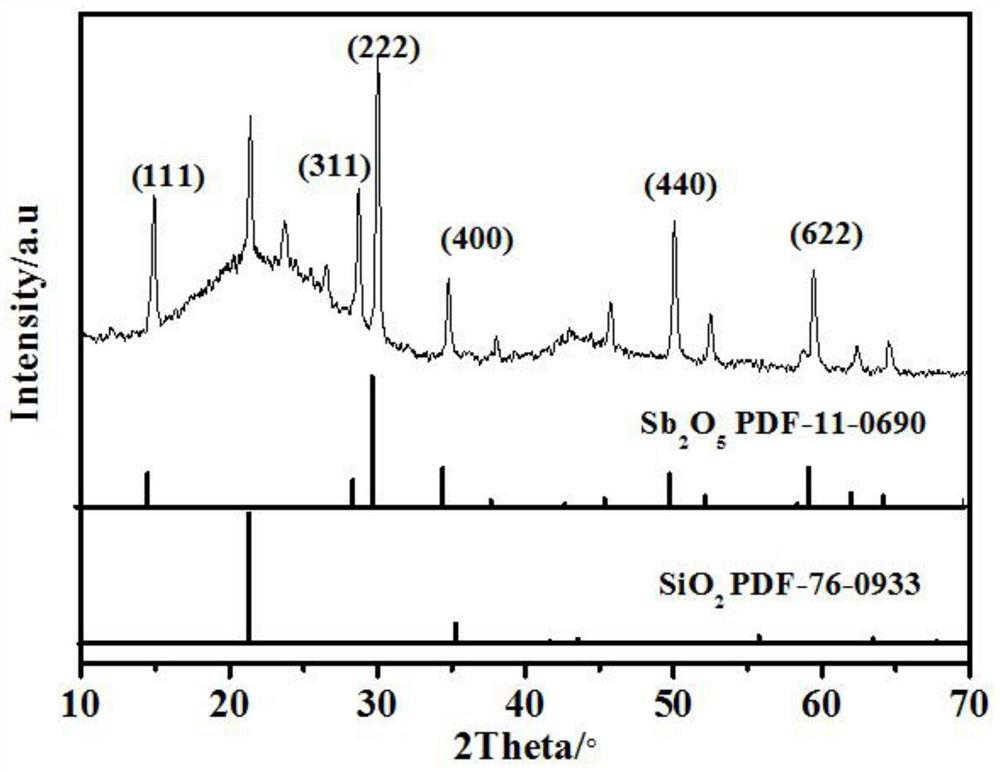

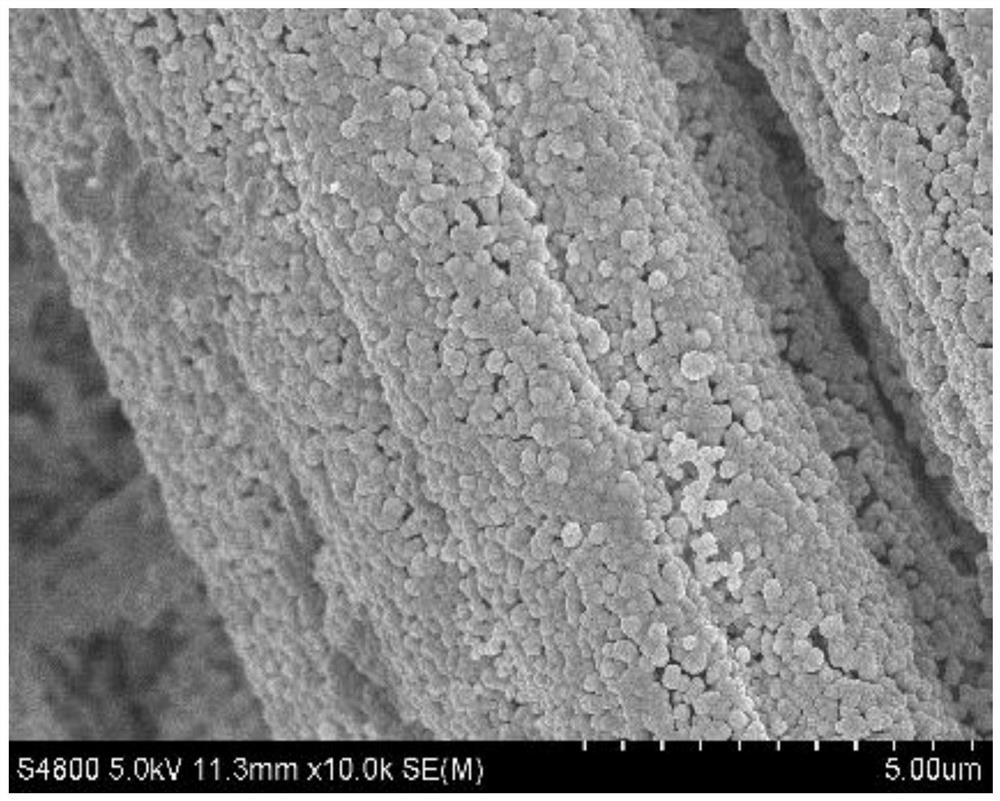

Preparation method of antimony pentoxide/polyacrylic acid/carbon cloth flexible sodium ion battery negative electrode material with mesh porous structure

ActiveCN110265644BGood shape retentionImprove mechanical propertiesCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention relates to a preparation method of an antimony pentoxide / polyacrylic acid / carbon cloth flexible sodium ion battery negative electrode material with a reticulate porous structure. The method comprises the following steps: 1, putting carbon cloth into acetone for soaking, cleaning and drying the carbon cloth, putting the dried carbon cloth into a polyacrylic acid aqueous solution for coating, and cleaning and drying the carbon cloth; 2, adding antimony trichloride into absolute ethanol to form an antimony trichloride solution, adding a sodium hydroxide aqueous solution into the antimony trichloride solution to adjust the pH value to obtain a mixed solution, and putting the coated carbon cloth into the mixed solution for soaking; and 3, transferring the carbon cloth and the mixed solution obtained in the step 2 into a reaction kettle for a hydrothermal reaction, cooling to the room temperature, and carrying out cleaning and drying to obtain the antimony pentoxide / polyacrylic acid / carbon cloth flexible sodium ion battery negative electrode material with the reticulate porous structure. The method is simple to operate and good in repeatability; a flexible electrode combines the characteristics of good mechanical property of the carbon cloth and high specific capacity of the antimony pentoxide; and the electrochemical cycling performance of the flexible electrode as the sodium ion battery negative electrode material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Treatment process, rejuvenation process, treatment composition, and treated component

ActiveUS20170080458A1Continuous combustion chamberVacuum evaporation coatingCeramic coatingGas turbines

A treatment composition is disclosed including a carrier and a sacrificial oxide-forming material suspended within the carrier. The sacrificial oxide-forming material is selected from the group consisting of tin oxide, magnesium oxide, antimony pentaoxide, and combinations thereof. A treatment process for a gas turbine component including an abradable ceramic coating is disclosed. The process includes contacting the abradable ceramic coating with the treatment composition. The sacrificial oxide-forming material is infused into the abradable ceramic coating to form sacrificial oxide-forming deposits within the abradable ceramic coating. A rejuvenation process is disclosed including contacting the hot gas path surface of a gas turbine component with a rinse composition comprising water and the treatment composition to form the sacrificial oxide-forming deposits within the abradable ceramic coating.

Owner:GENERAL ELECTRIC CO

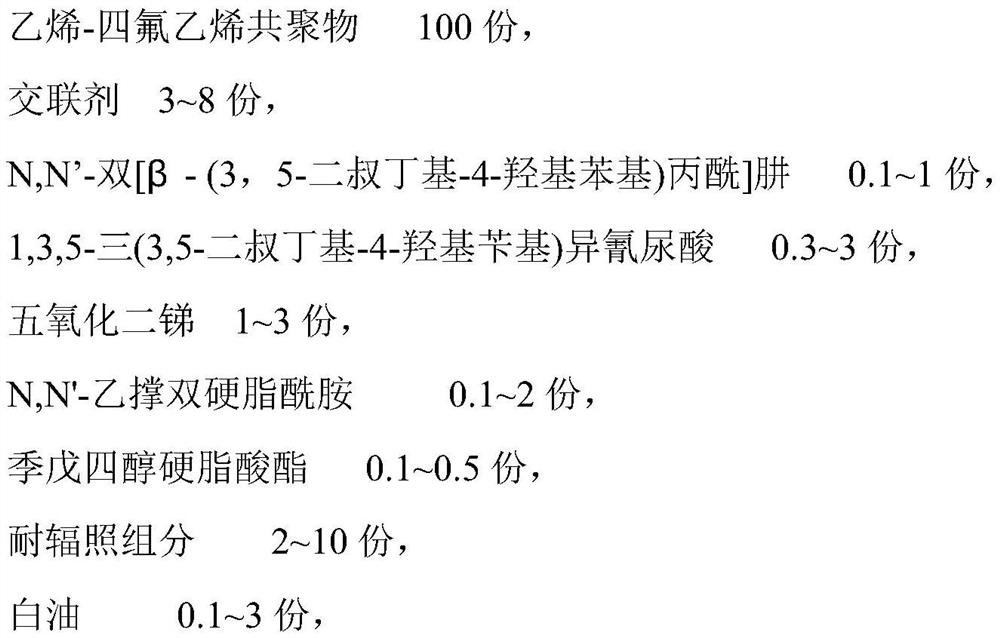

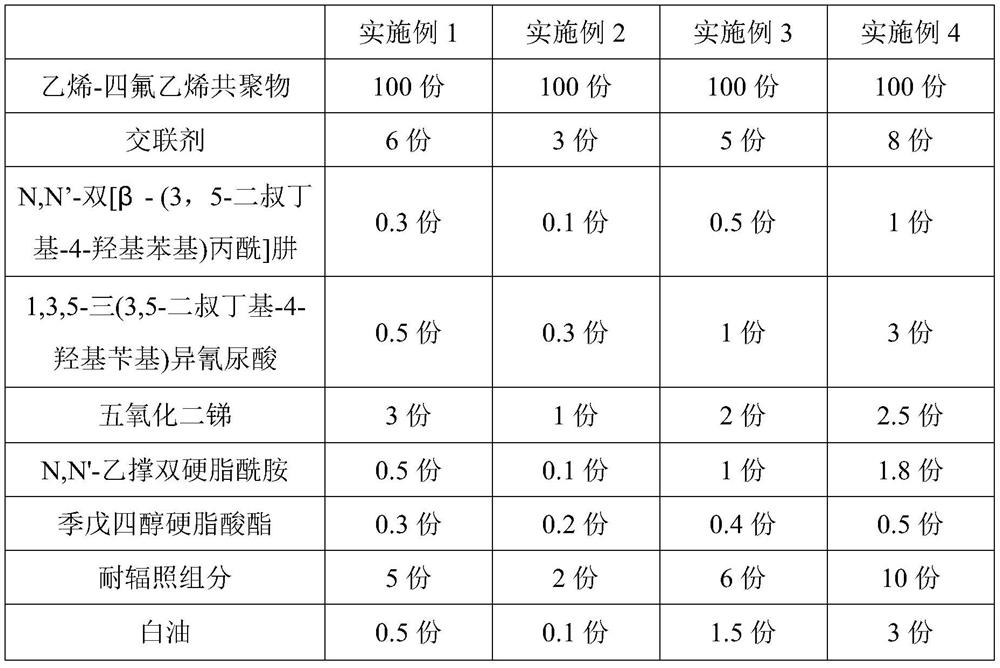

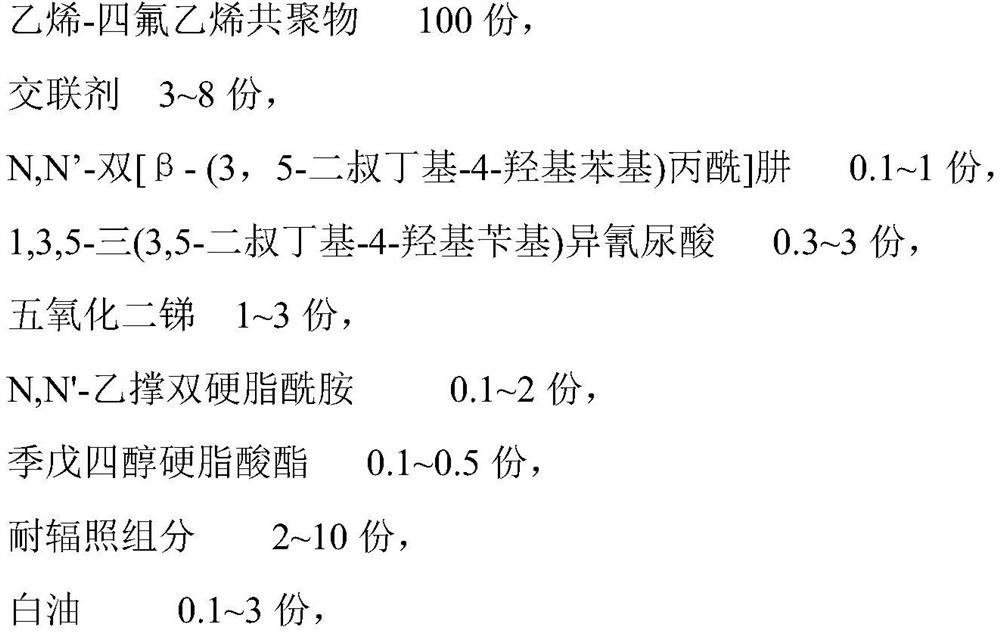

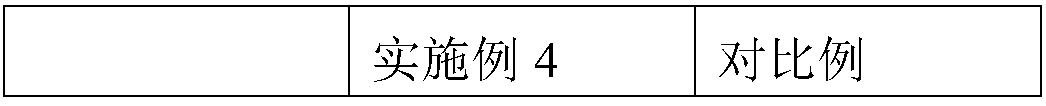

Radiation-resistant cross-linked ethylene-tetrafluoroethylene copolymer insulating material

ActiveCN110483878BImprove radiation resistanceBest practicePlastic/resin/waxes insulatorsPolymer scienceCross linker

The invention relates to a radiation-resistant crosslinked ethylene-tetrafluoroethylene copolymer insulating material, which comprises the following components in parts by mass: 100 parts of ethylene-tetrafluoroethylene copolymer, 3-8 parts of crosslinking agent, N, N' ‑Bis[β‑(3,5‑di-tert-butyl‑4‑hydroxyphenyl)propionyl]hydrazine0.1~1 part, 1,3,5‑tris(3,5‑di-tertbutyl‑4‑hydroxy 0.3-3 parts of benzyl)isocyanuric acid, 1-3 parts of antimony pentoxide, 0.1-2 parts of N,N'-ethylene bisstearamide, 0.1-0.5 parts of pentaerythritol stearate, radiation-resistant group 2 to 10 parts, 0.1 to 3 parts of white oil. The invention can more stably and efficiently improve the radiation resistance performance of the crosslinked ethylene-tetrafluoroethylene copolymer insulating material.

Owner:中广核高新核材科技(苏州)有限公司

A kind of preparation method of antimony pentoxide composite dry powder

InactiveCN104355333BImprove stabilityImprove flame retardant performanceAntimony oxides/hydroxides/oxyacidsPhosphateCreatinol phosphate

The invention relates to a preparation method of an antimony pentoxide composite powder. The preparation method comprises the following steps: firstly, antimony trioxide is taken for refining; then the refined antimony trioxide dry powder is added into water, then creatinol-o-phosphate as a stabilizer and oxydol are added for oxidation reflux reaction, after the reaction, a reacting liquid is taken for dialysis for 2 to 3 times, redundant creation o-phosphate is removed, and an antimony pentoxide hydrosol is prepared; finally, the prepared antimony pentoxide hydrosol is added with zeolite powder, the mixture is stirred and then left to stand, precipitate is obtained through centrifugation, and the precipitate is filtered and dried so as to obtain the antimony pentoxide composite powder. The preparation method provided by the invention uses the creatinol-o-phosphate as the stabilizer, and the creatinol-o-phosphate contains a plurality of hydroxies and two inflaming retarding elements N and P, so that the stabilizing effect is good, the flame-retardant effect of the colloid of antimony pentoxide is improved, a zeolite powder is adopted for adsorbing the colloid of antimony pentoxide, so as to prepare the antimony pentoxide-zeolite powder composite powder, during the preparing process, the problem of much loss of antimony pentoxide dry powder during the drying process caused by relatively fine antimony pentoxide dry powder can be solved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Preparation of Composite Antimony Trioxide and Its Application in High Flame Retardancy EVA Foaming Materials

ActiveCN107022110BImprove flame retardant performanceAntimony oxides/hydroxides/oxyacidsAluminium hydroxideFire resistance

The invention discloses compound antimonous oxide preparation and application thereof in high-fire-resistance EVA foaming material. Antimony oxide and carbon monoxide are utilized to be prepared into an antimonous oxide crude product under alkaline condition through assistance of carbon dioxide supercritical reaction, and the antimonous oxide crude product is mixed with aluminum hydroxide to be prepared into the compound antimonous oxide through an ultrasonic precipitation method. Fire resistance of the antimonous oxide is effectively enhanced under the premises of avoiding halogen flame retardant and reducing use of aluminum hydroxide flame retardant; the prepared foaming material not only has varieties of excellent performance of an ordinary foaming material, but also has excellent fire resistance when the antimonous oxide is applied to preparation of the EVA foaming material; an application range of the foaming material in varieties of inflammable building package materials is widened.

Owner:SANSD JIANGSU ENVIRONMENTAL PROTECTION TECH

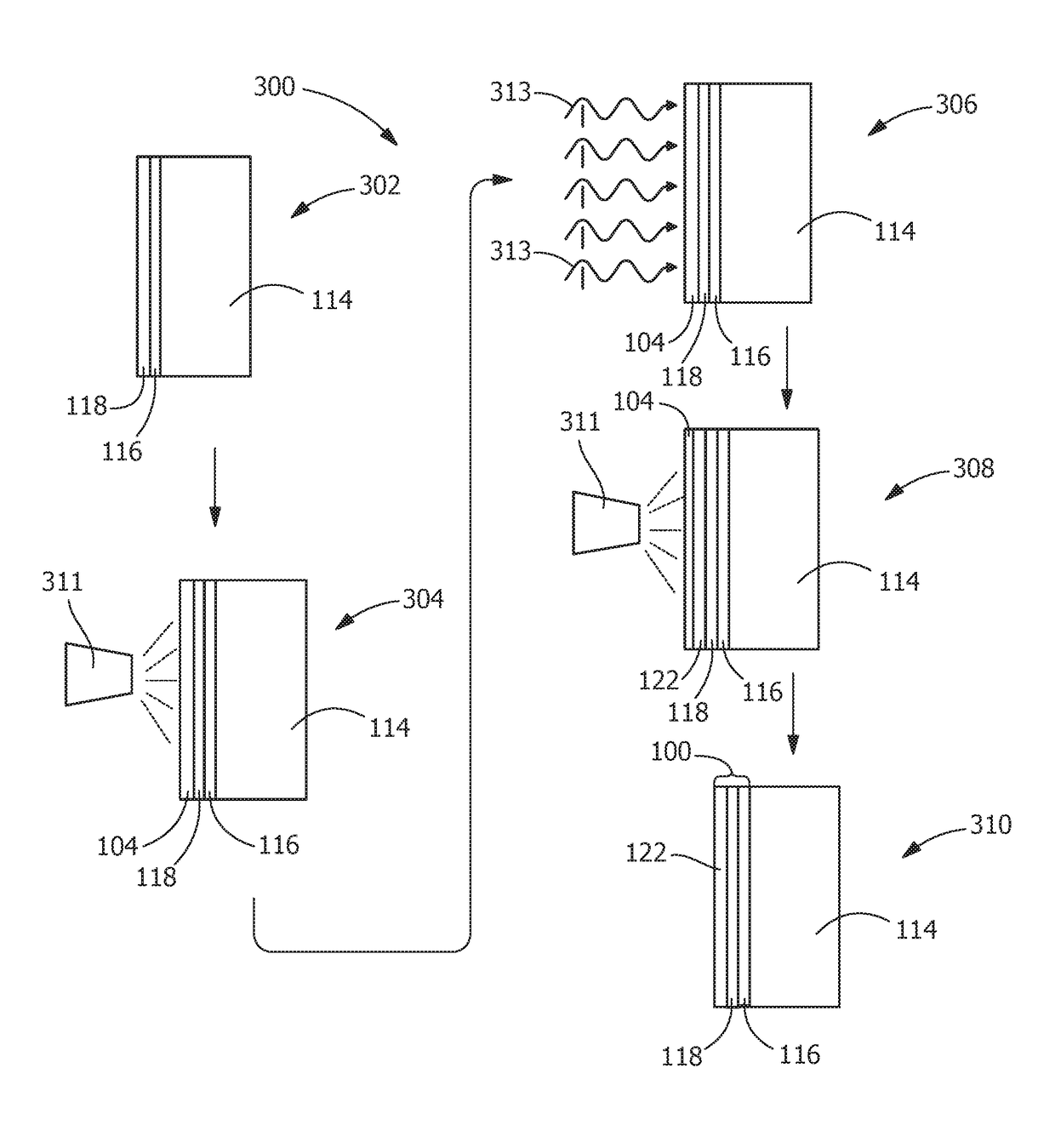

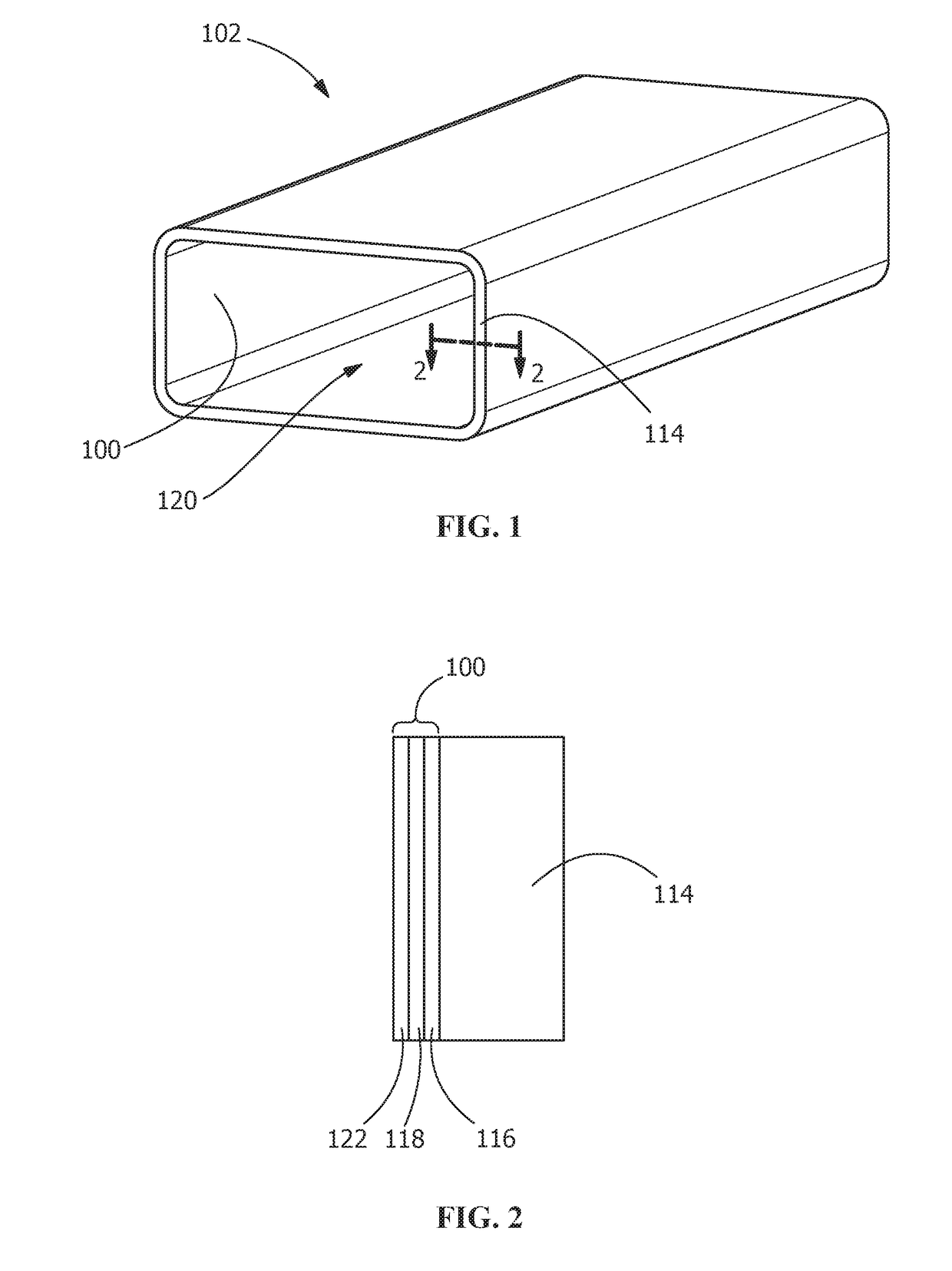

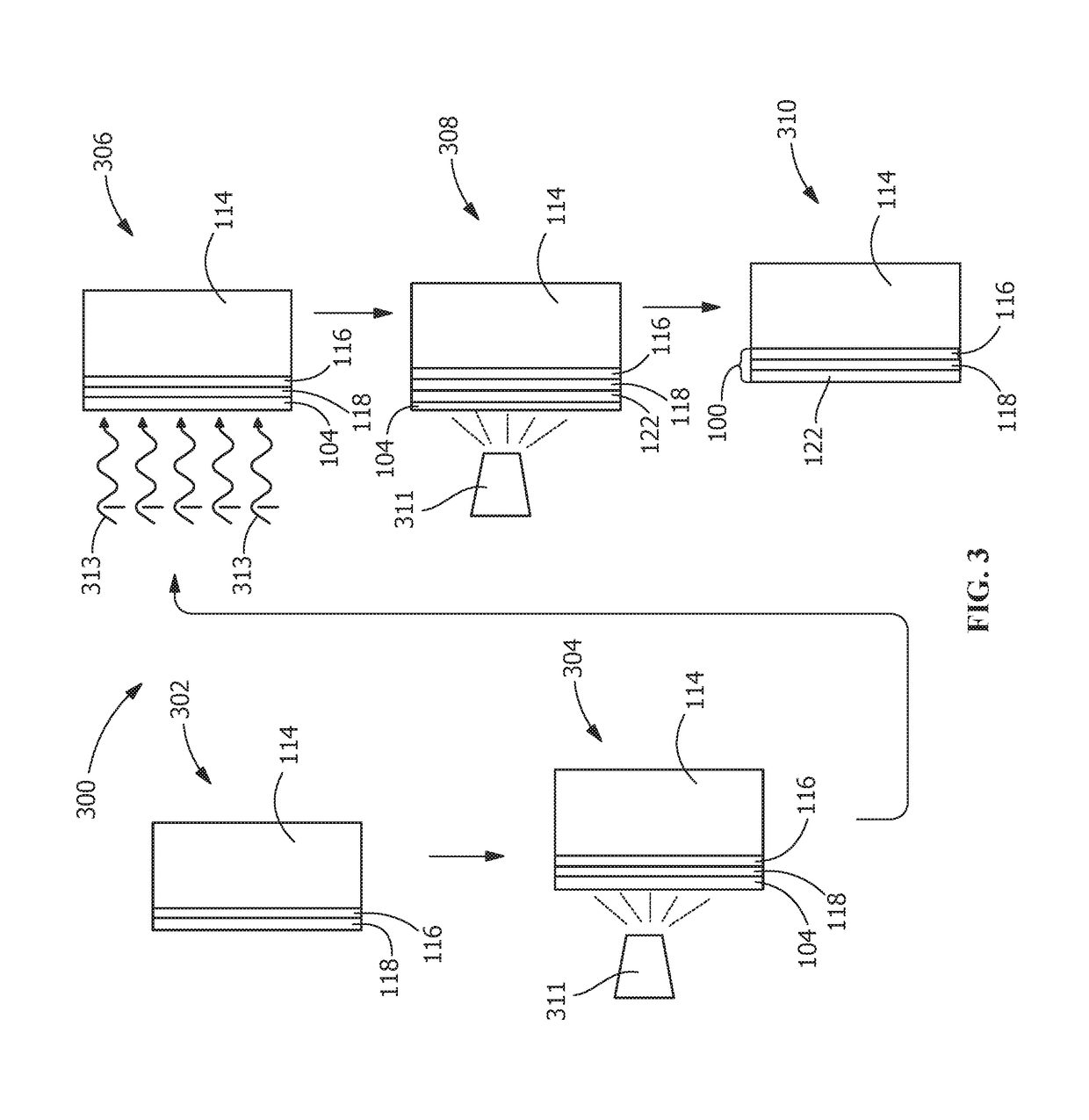

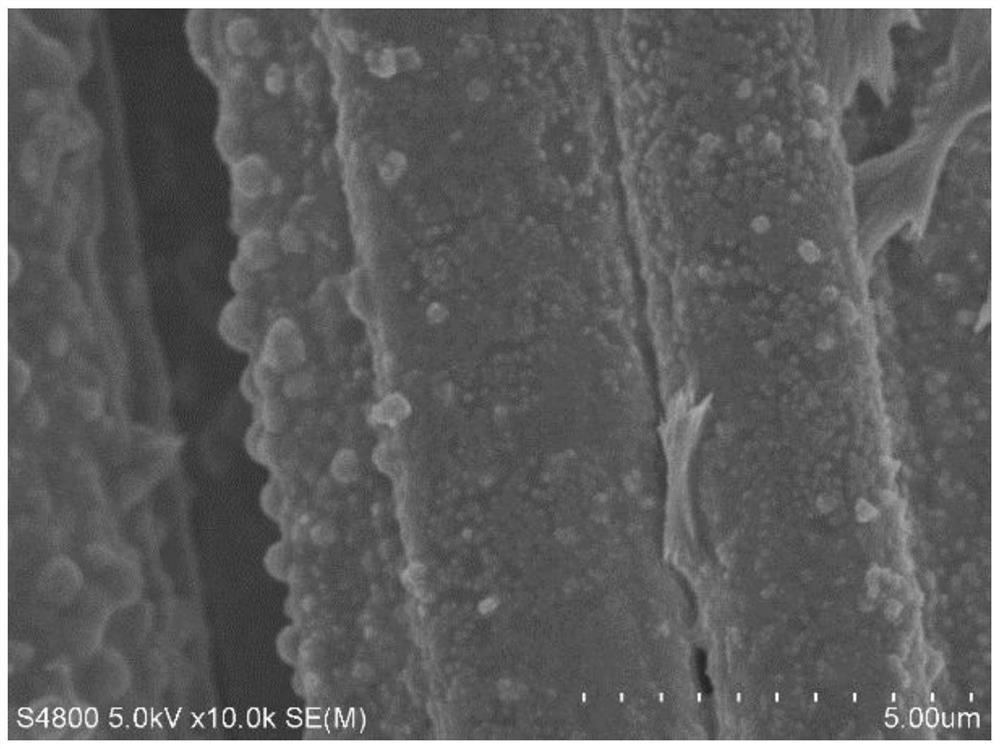

Preparation of a flexible antimony pentoxide/silicon dioxide/carbon cloth material and its application as a negative electrode for sodium-ion batteries

The invention discloses the preparation of a flexible antimony pentoxide / silicon dioxide / carbon cloth material and its application as a negative electrode of a sodium ion battery. After grinding silicon dioxide, it is added to deionized water and dissolved to obtain solution A; Antimony trichloride was added into the ethanol solution and dissolved to obtain antimony trichloride solution, adding sodium hydroxide aqueous solution to the antimony trichloride solution to adjust its pH to obtain solution B; adding solution A to solution B and stirring to obtain Solution C: place activated carbon in solution C for impregnation, transfer solution C and carbon cloth to a reaction kettle for hydrothermal reaction, cool to room temperature, take out carbon cloth, wash and dry to obtain antimony pentoxide / silicon dioxide / Carbon cloth flexible anode material for sodium-ion batteries. Its operation is simple, the cost is low and silicon material can be applied to the negative electrode material of sodium ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com