Modified recycled plastic particle with flame retardancy

A technology of recycled plastic particles and flame retardancy, applied in the field of modified recycled plastic particles, can solve the problems of easy fire, not very good flame retardancy, low efficiency, etc., and achieve strong flame retardancy, improve efficiency, and improve weather resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

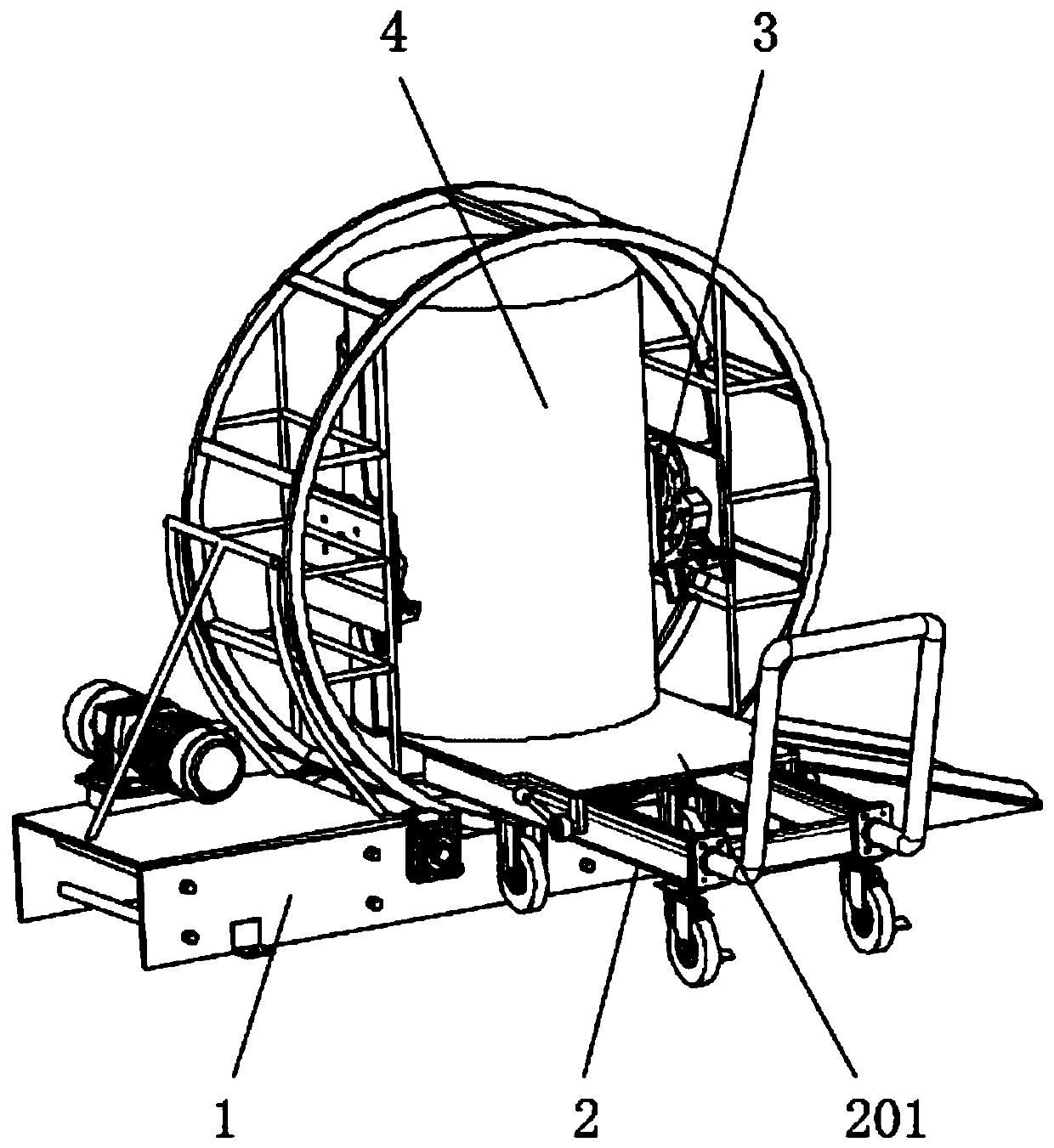

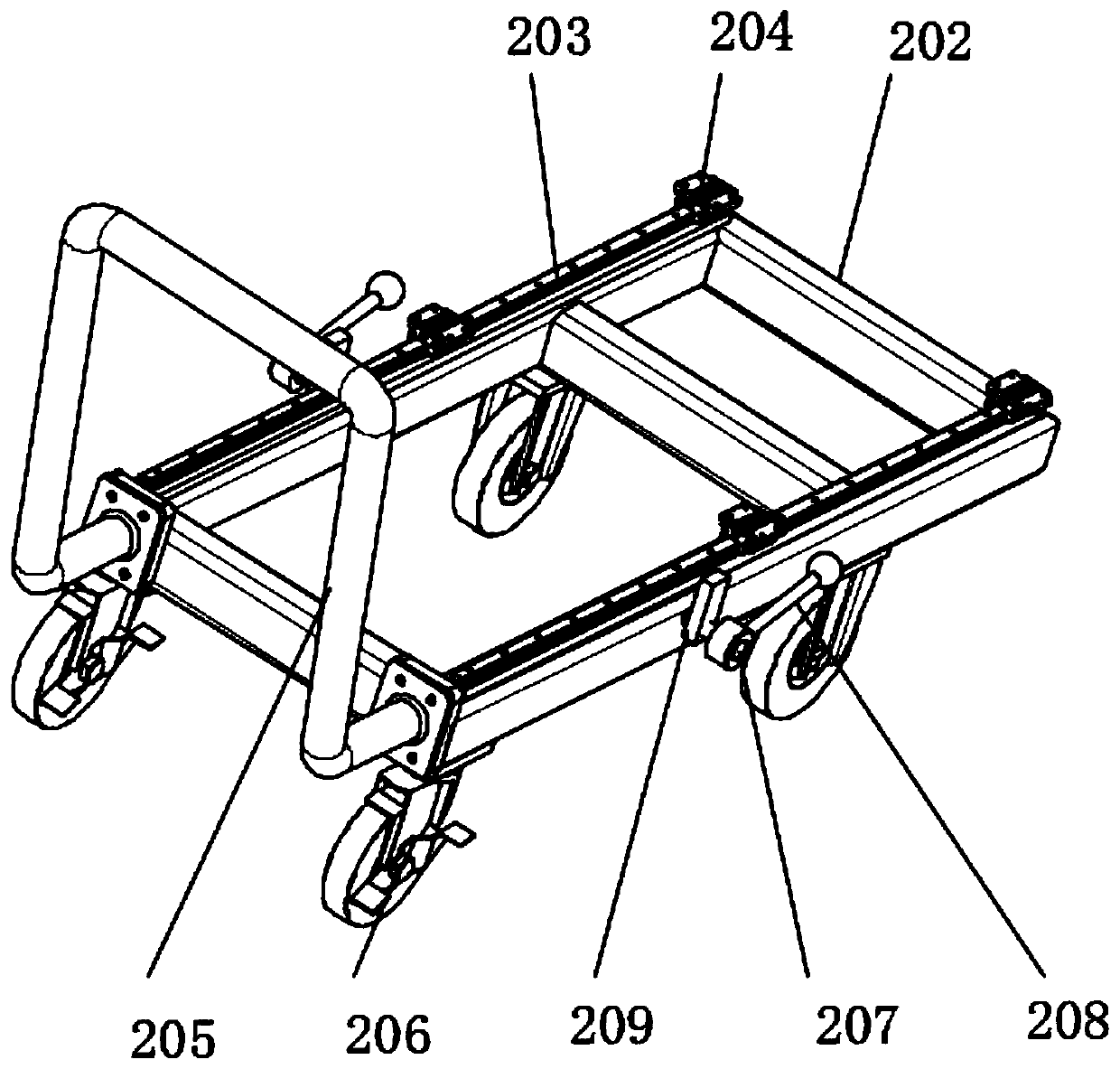

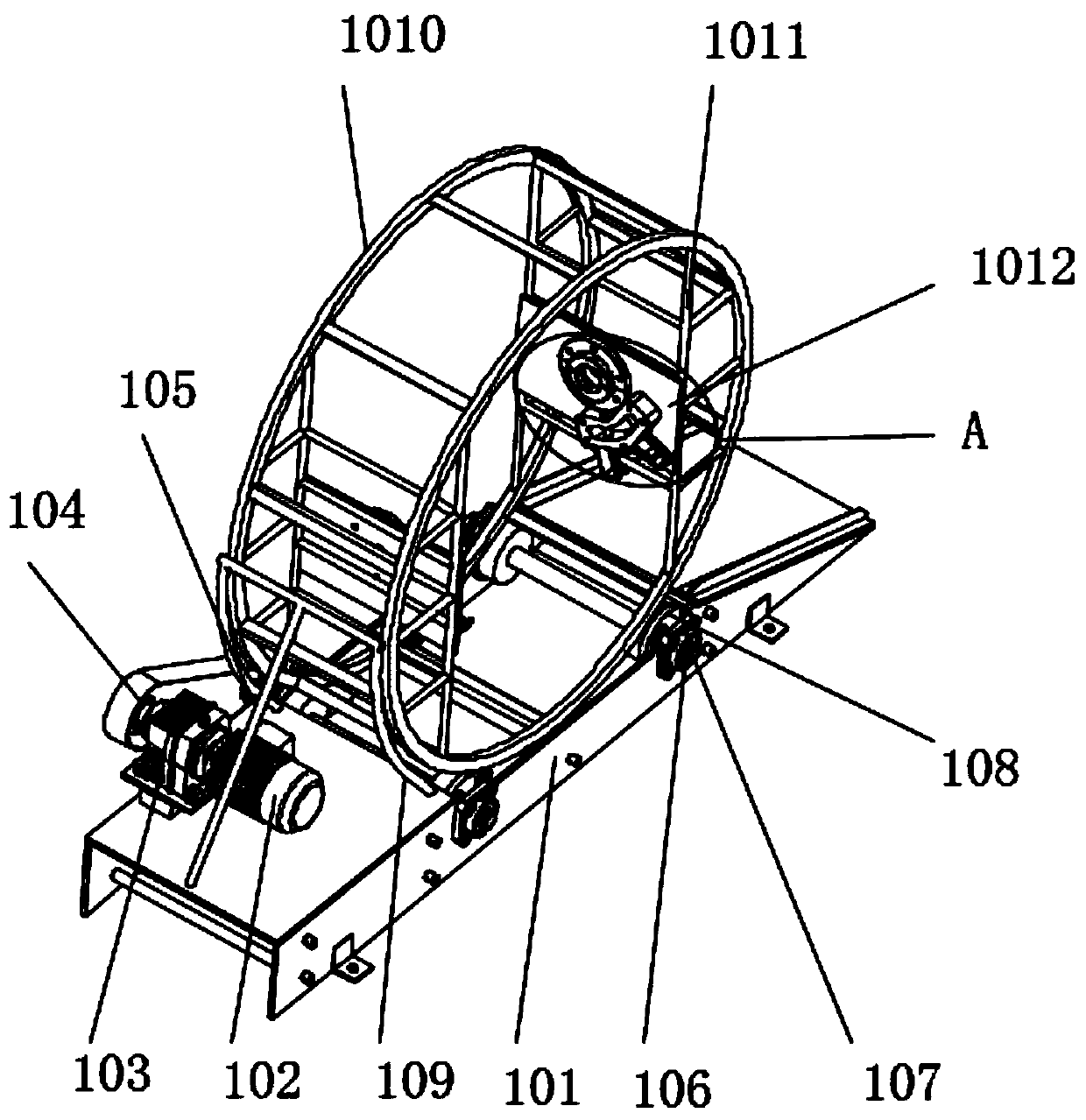

Image

Examples

preparation example Construction

[0033] The preparation method of described intumescent flame retardant comprises the following steps:

[0034] S1: Diethylamine and phosphorus oxychloride are reacted in a solvent to generate phosphorus-containing, nitrogen-containing intermediate diethyl dichlorophosphonamide, and the molar ratio of diethylamine and phosphorus oxychloride is 1:1 to 1:5; The solvent is any one of chlorobenzene, benzene, chloroform and dichloromethane or a mixture of any proportion thereof, and the reaction temperature is controlled at -15-0°C; the reaction time is 3-15h;

[0035] S2: diethyl dichlorophosphonamide reacts with hexamethylenediamine under the introduction of an inert gas, and the product is filtered, washed, and dried to obtain a light yellow viscous liquid to obtain an intumescent flame retardant. The inert gas used is nitrogen, or Argon or helium, the reaction temperature is 25-75°C, and the reaction time is 8-22h.

[0036] The antioxidant is at least one of hydroquinone, diphe...

Embodiment 1

[0050] A modified recycled plastic particle with flame retardancy, comprising the following raw materials in parts by weight: 28 parts of polyethylene, 16 parts of polycarbonate, 21 parts of polycaprolactone, 5 parts of hexabromocyclododecane, antimony trioxide 4 parts, 4 parts of antimony pentoxide, 6 parts of nano silicon dioxide, 7 parts of glass fiber, 14 parts of pigment and filler, 6 parts of coupling agent, 7 parts of dispersant, 4 parts of stabilizer, 7 parts of plasticizer, anti 3 parts of oxidizing agent, 7 parts of intumescent flame retardant;

[0051] The preparation method of described intumescent flame retardant comprises the following steps:

[0052] S1: Diethylamine and phosphorus oxychloride are reacted in a solvent to generate phosphorus-containing, nitrogen-containing intermediate diethyl dichlorophosphonamide, and the molar ratio of diethylamine and phosphorus oxychloride is 1:1 to 1:5; The solvent is any one of chlorobenzene, benzene, chloroform and dichl...

Embodiment 2

[0059] A modified recycled plastic particle with flame retardancy, comprising the following raw materials in parts by weight: 28 parts of polyethylene, 16 parts of polycarbonate, 21 parts of polycaprolactone, 5 parts of hexabromocyclododecane, antimony trioxide 4 parts, 4 parts of antimony pentoxide, 6 parts of nano silicon dioxide, 7 parts of glass fiber, 14 parts of pigment and filler, 6 parts of coupling agent, 7 parts of dispersant, 4 parts of stabilizer, 7 parts of plasticizer, anti 0 parts of oxidizing agent, 5 parts of intumescent flame retardant;

[0060] The preparation method of described intumescent flame retardant comprises the following steps:

[0061] S1: Diethylamine and phosphorus oxychloride are reacted in a solvent to generate phosphorus-containing, nitrogen-containing intermediate diethyl dichlorophosphonamide, and the molar ratio of diethylamine and phosphorus oxychloride is 1:1 to 1:5; The solvent is any one of chlorobenzene, benzene, chloroform and dichl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com