Colloidal antimony pentoxide manufacturing device and method

A device-making technology for antimony pentoxide, which is applied in the fields of colloid chemistry, colloid chemistry, chemical instruments and methods, etc. It can solve the problems of affecting product viscosity, high energy consumption, and reducing thermal efficiency, so as to speed up the reaction speed and simplify the structure of the device , The effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

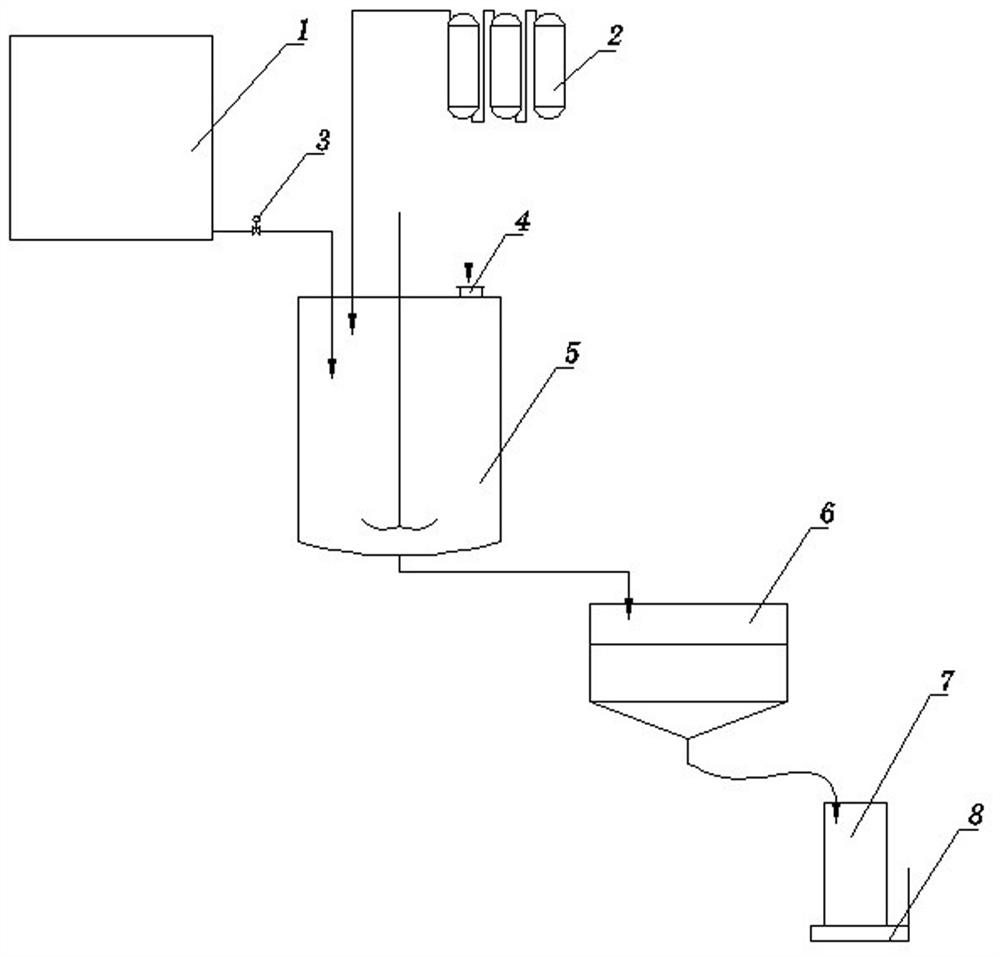

[0029] 1. Add 180kg of deionized water into the microwave reactor 5, start stirring, and then add 100kg of Sb 2 o 3 , add catalyst sodium tartrate 0.1kg, Sb 2 o 3 Heat the slurry to 50°C, start adding hydrogen peroxide slowly, control the flow rate of hydrogen peroxide at 5 liters / min, add 100 L of hydrogen peroxide in total, and the addition time of hydrogen peroxide is generally 20-30 minutes;

[0030] 2. After the mixed solution reacts for 5 minutes, turn off the microwave and stir.

[0031] 3. The product to be reacted is a homogeneous colloid with a translucent texture. The test results are as follows: Sb 2 o 5 : 33.91%, Sb 2 o 3 : 0.18%, calculated according to the test results and mixed with a certain amount of deionized water to make Sb 2 o 5 The concentration is 30%;

[0032] 4. Assay approval for Sb 2 o 5 Concentration, filter by filtering device 6 again, then pack by packaging drum 7, metering device...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] 1. Add 300kg of deionized water into the microwave reactor 5, start stirring, and then add 100kg of Sb 2 o 3 , adding 0.1Kg catalyst sodium citrate, the Sb 2 o 3 Heat the slurry to 50°C, start to add hydrogen peroxide slowly, control the flow rate of hydrogen peroxide at 5L / min, add 100L of hydrogen peroxide in total, and the addition time of hydrogen peroxide is generally 20-30min;

[0036] 2. After the mixed solution reacts for 5 minutes, test the volume and specific gravity of the colloidal solution, judge the approximate concentration under the specific gravity according to the specific gravity, and then calculate Sb 2 o 5 The volume when the concentration is 48%, then continue to concentrate with microwave heating, after reaching the proper volume and specific gravity when the concentration is 48%, turn off the microwave and stir, take a sample test, the test results are as follows: Sb 2 o 5 : 48.1%, Sb ...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] 1. Add 300kg of deionized water into the microwave reactor, start stirring, and then add 100kg of Sb 2 o 3 , add 0.1kg catalyst sodium salicylate, add 18kg triethanolamine, Sb 2 o 3 Heat the slurry to 50°C, start to add hydrogen peroxide slowly, control the flow rate of hydrogen peroxide at 5L / min, add 100L of hydrogen peroxide in total, and the addition time of hydrogen peroxide is generally 20-30min;

[0041] 2. After the mixed solution reacts for 5 minutes, test the volume and specific gravity of the colloidal solution, judge the approximate concentration under the specific gravity according to the specific gravity, and then calculate Sb 2 o 3 The volume when the concentration is 24%, and then continue to concentrate with microwave heating to reach Sb 2 o 3 When the concentration is 24%, after the proper volume and specific gravity, turn off the microwave and stir, take a sample for testing, and the testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com