Cyclic lead-acid storage battery positive electrode lead paste formula and preparation method thereof

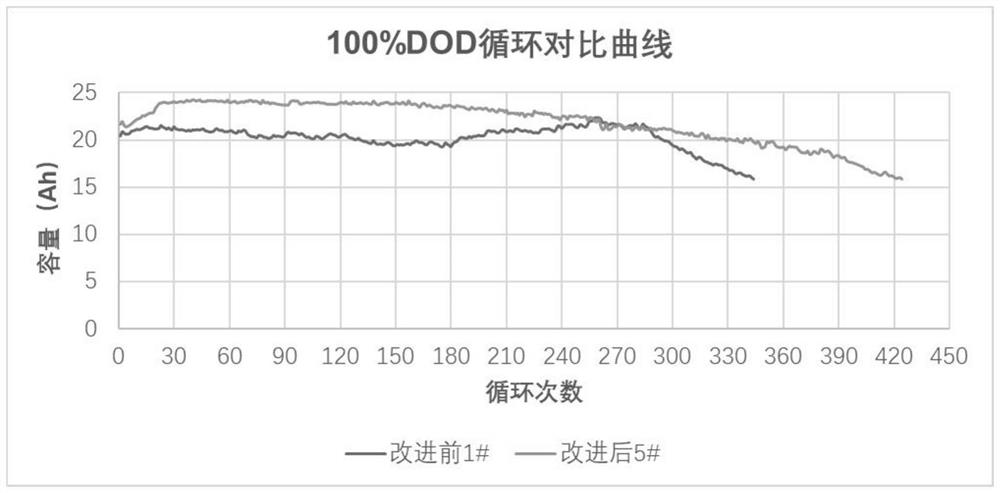

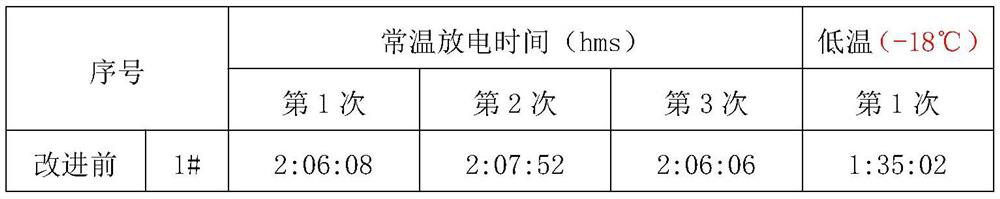

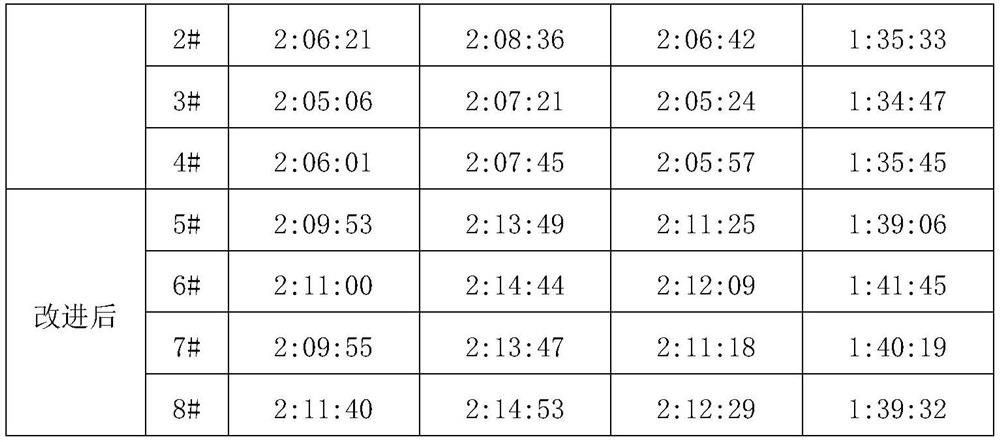

A lead-acid battery, positive lead paste technology, applied in lead-acid batteries, electrode manufacturing, battery electrodes, etc., to enhance the conductivity and improve the capacity of normal and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A positive lead paste formula for a circulating lead-acid battery, the mass percentage of each component relative to lead powder: 8% dilute sulfuric acid, 8% deionized water, 0.05% short fiber, 0.1% colloidal graphite, 0.05% stannous sulfate, pentoxide Diantimony 0.05% and lead powder.

[0025] The density of dilute sulfuric acid at 25°C is 1.400±0.002g / cm 3 , stannous sulfate and antimony pentoxide are analytical grade, antimony pentoxide particle size distribution range: 0.2 ~ 1.8μm, D50 range: 0.45 ~ 0.55μm, lead powder oxidation degree of 72 ~ 78%.

[0026] The material of above-mentioned mass percentage is prepared according to the following steps:

[0027] S1. Dry mixing of materials: add lead powder, short fiber, stannous sulfate and antimony pentoxide with appropriate mass percentages into the mixing chamber for dry mixing, and the dry mixing time is 5.5 minutes;

[0028] S2. Wet mixing of materials: for the mixture in S1, quickly add water within 1 minute, an...

Embodiment 2

[0033] A positive lead paste formula for a circulating lead-acid battery, the mass percentages of each component relative to the lead powder: dilute sulfuric acid 10%, deionized water 12%, short fiber 0.05%, colloidal graphite 0.12%, stannous sulfate 0.12%, pentoxide Diantimony 0.12% and lead powder.

[0034] The density of dilute sulfuric acid at 25°C is 1.400±0.002g / cm 3 , stannous sulfate and antimony pentoxide are analytical grade, antimony pentoxide particle size distribution range: 0.2 ~ 1.8μm, D50 range: 0.45 ~ 0.55μm, lead powder oxidation degree of 72 ~ 78%.

[0035] The material of above-mentioned mass percentage is prepared according to the following steps:

[0036] S1. Dry mixing of materials: add lead powder, short fiber, stannous sulfate and antimony pentoxide with appropriate mass percentages into the mixing chamber for dry mixing, and the dry mixing time is 5.5 minutes;

[0037] S2. Wet mixing of materials: for the mixture in S1, quickly add water within 1 mi...

Embodiment 3

[0042] A positive lead paste formula for a circulating lead-acid battery, the mass percentages of each component relative to the lead powder: dilute sulfuric acid 9%, deionized water 10%, short fiber 0.085%, colloidal graphite 0.25%, stannous sulfate 0.85%, pentoxide Diantimony 0.085% and lead powder.

[0043] The density of dilute sulfuric acid at 25°C is 1.400±0.002g / cm 3 , stannous sulfate and antimony pentoxide are analytical grade, antimony pentoxide particle size distribution range: 0.2 ~ 1.8μm, D50 range: 0.45 ~ 0.55μm, lead powder oxidation degree of 72 ~ 78%.

[0044] The material of above-mentioned mass percentage is prepared according to the following steps:

[0045] S1. Dry mixing of materials: add lead powder, short fiber, stannous sulfate and antimony pentoxide with appropriate mass percentages into the mixing chamber for dry mixing, and the dry mixing time is 5.5 minutes;

[0046] S2. Wet mixing of materials: for the mixture in S1, quickly add water within 1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com