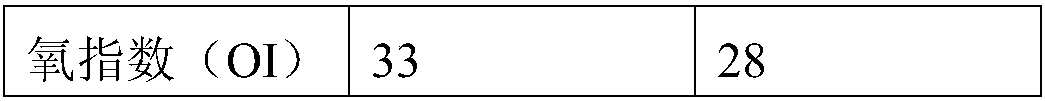

Preparation of Composite Antimony Trioxide and Its Application in High Flame Retardancy EVA Foaming Materials

A technology of antimony trioxide and antimony pentoxide, applied in antimony oxide/antimony hydroxide/antimony oxyacids, inorganic chemistry, antimony compounds, etc., can solve problems such as suffocation, non-compliance with ROHS instructions, and large usage , to achieve the effect of broadening the application range, excellent flame retardant performance, and enhancing flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of composite antimony trioxide comprises the following steps:

[0021] (1) Put antimony pentoxide and sodium hydroxide solution into the supercritical reactor, feed reducing agent carbon monoxide, open the ultrasonic device, control the temperature to be 300 ° C, the pressure is 10MPa, open the carbon dioxide cylinder after the reaction 20min, carbon dioxide gas After being cooled by a cooler into a liquid, it is pressurized by a high-pressure pump and then enters the reactor, and the reaction is continued for 20min;

[0022] (2) opening the pressure relief port and reducing the pressure in the supercritical reactor to normal pressure to obtain powder;

[0023] (3) calcining the collected powder at a temperature of 800° C. to obtain the primary product of antimony trioxide;

[0024] (4) The primary product of antimony trioxide and aluminum hydroxide are prepared into composite antimony trioxide by ultrasonic precipitation in a mass ratio of 5:1.

Embodiment 2

[0026] The preparation of composite antimony trioxide comprises the following steps:

[0027] (1) antimony pentoxide and potassium hydroxide solution are put into supercritical reactor, feed reducing agent carbon monoxide, open ultrasonic device, control temperature is 350 ℃, pressure is 15MPa, open carbon dioxide steel cylinder after reaction 30min, carbon dioxide gas After being cooled into a liquid by a cooler, it is pressurized by a high-pressure pump and then enters the reaction kettle, and the reaction is continued for 40min;

[0028] (2) opening the pressure relief port and reducing the pressure in the supercritical reactor to normal pressure to obtain powder;

[0029] (3) calcining the collected powder at a temperature of 900 ° C to obtain the primary product of antimony trioxide;

[0030] (4) The primary product of antimony trioxide and aluminum hydroxide are prepared into composite antimony trioxide by ultrasonic precipitation in a mass ratio of 5:1.

Embodiment 3

[0032] The preparation of composite antimony trioxide comprises the following steps:

[0033] (1) Put antimony pentoxide and sodium hydroxide solution into the supercritical reactor, feed reducing agent carbon monoxide, open the ultrasonic device, control the temperature to be 330 ° C, the pressure is 13MPa, open the carbon dioxide cylinder after the reaction 25min, carbon dioxide gas After being cooled by a cooler into a liquid, it is pressurized by a high-pressure pump and then enters the reactor, and the reaction is continued for 30min;

[0034] (2) opening the pressure relief port and reducing the pressure in the supercritical reactor to normal pressure to obtain powder;

[0035] (3) calcining the collected powder at a temperature of 850° C. to obtain a primary product of antimony trioxide;

[0036] (4) The primary product of antimony trioxide and aluminum hydroxide are prepared into composite antimony trioxide by ultrasonic precipitation in a mass ratio of 5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com