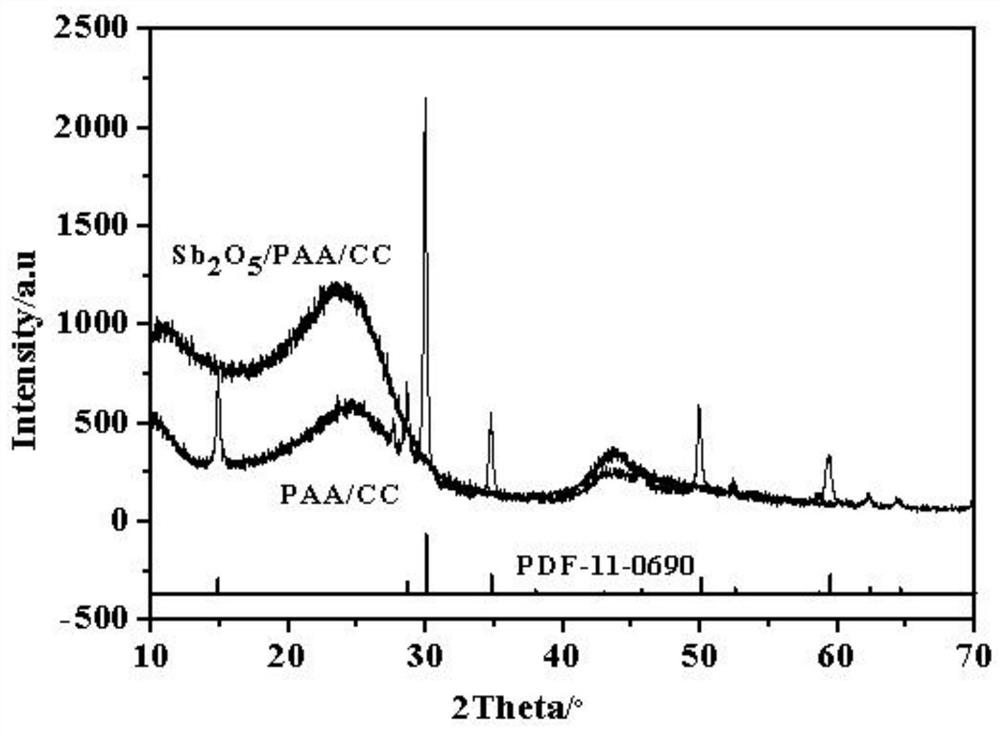

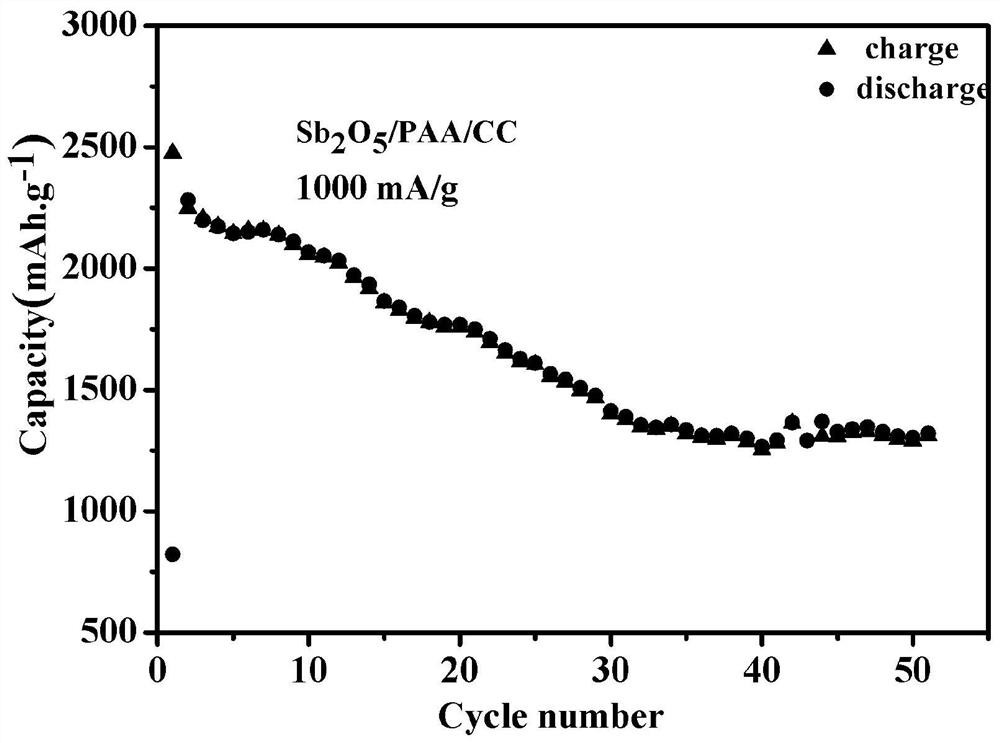

Preparation method of antimony pentoxide/polyacrylic acid/carbon cloth flexible sodium ion battery negative electrode material with mesh porous structure

An antimony pentoxide and sodium ion battery technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems that have not appeared in the report, and achieve good mechanical properties, good shape retention, and high repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

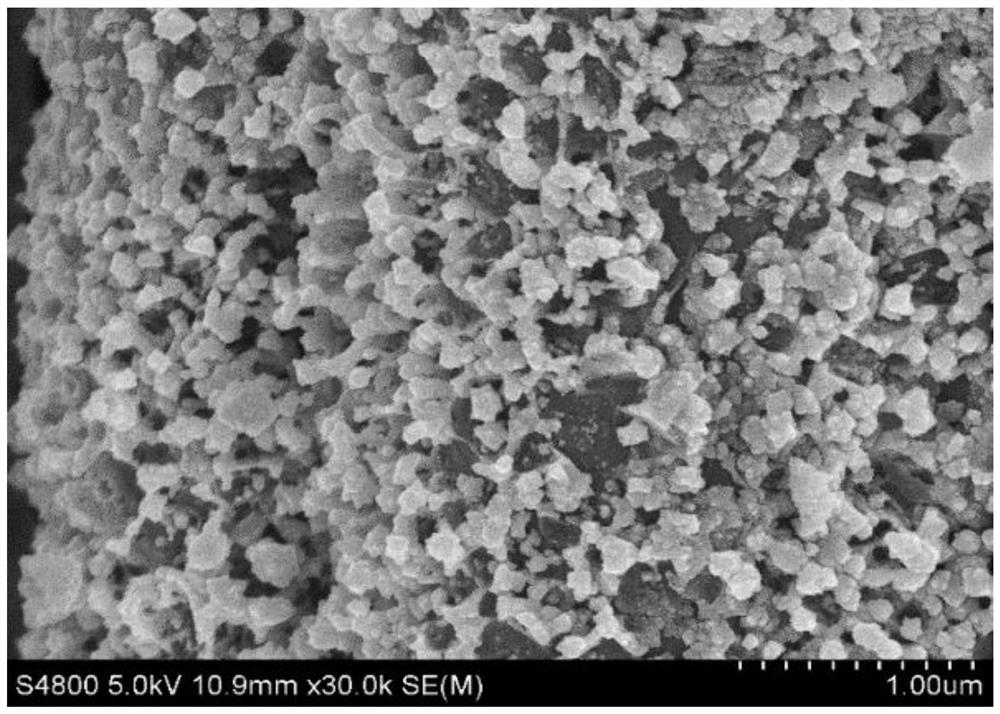

[0025] A preparation method of antimony pentoxide / polyacrylic acid / carbon cloth flexible sodium ion battery negative electrode material with mesh porous structure, comprising the following steps:

[0026] Step 1: Soak the hydrophilic carbon cloth with a size of 4cm*2cm in 50mL acetone for 24 hours to remove surface impurities, then wash it repeatedly with deionized water and absolute ethanol, and place the carbon cloth in an oven at 60°C to dry Dry; then place the dried carbon cloth into 1mg / mL polyacrylic acid aqueous solution for 1h for coating treatment, wash it repeatedly with deionized water and absolute ethanol respectively, place the carbon cloth in an oven at 60°C and then dry it ; Wherein, polyacrylic acid average molecular weight is 1250000;

[0027] Step 2: Add 0.3g antimony trichloride to 20mL of absolute ethanol and stir magnetically to form an antimony trichloride solution, add 0.06g / mL sodium hydroxide aqueous solution to the antimony trichloride solution to adj...

Embodiment 2

[0030] A preparation method of antimony pentoxide / polyacrylic acid / carbon cloth flexible sodium ion battery negative electrode material with mesh porous structure, comprising the following steps:

[0031]Step 1: Soak the hydrophilic carbon cloth with a size of 4cm*2cm in 50mL acetone for 36 hours to remove surface impurities, then wash it repeatedly with deionized water and absolute ethanol, and place the carbon cloth in an oven at 60°C to dry Dry; then place the dried carbon cloth into 3mg / mL polyacrylic acid aqueous solution for 1h for coating treatment, wash it repeatedly with deionized water and absolute ethanol respectively, place the carbon cloth in an oven at 60°C and then dry it ; Wherein, polyacrylic acid average molecular weight is 1250000;

[0032] Step 2: Add 0.57g antimony trichloride to 20mL of absolute ethanol and stir magnetically to form an antimony trichloride solution, add 0.08g / mL sodium hydroxide aqueous solution to the antimony trichloride solution to adj...

Embodiment 3

[0035] A preparation method of antimony pentoxide / polyacrylic acid / carbon cloth flexible sodium ion battery negative electrode material with mesh porous structure, comprising the following steps:

[0036] Step 1: Soak the hydrophilic carbon cloth with a size of 4cm*2cm in 50mL acetone for 72 hours to remove surface impurities, then wash it repeatedly with deionized water and absolute ethanol, and place the carbon cloth in an oven at 60°C to dry Dry; then place the dried carbon cloth into a 6mg / mL polyacrylic acid aqueous solution for 3 hours for coating treatment, wash it repeatedly with deionized water and absolute ethanol respectively, and place the carbon cloth in an oven at 60°C for further coating. drying; wherein, the average molecular weight of polyacrylic acid is 1,250,000;

[0037] Step 2: Add 0.57g antimony trichloride to 20mL of absolute ethanol and stir magnetically to form an antimony trichloride solution, add 0.06g / mL sodium hydroxide aqueous solution to the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com