Radiation-resistant cross-linked ethylene-tetrafluoroethylene copolymer insulating material

A technology of tetrafluoroethylene and cross-linked ethylene, used in insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of high smoke generation, easy self-polymerization of cross-linking agents, and radiation resistance to be improved. , to achieve the effect of excellent radiation resistance, efficient radiation resistance, and improved radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

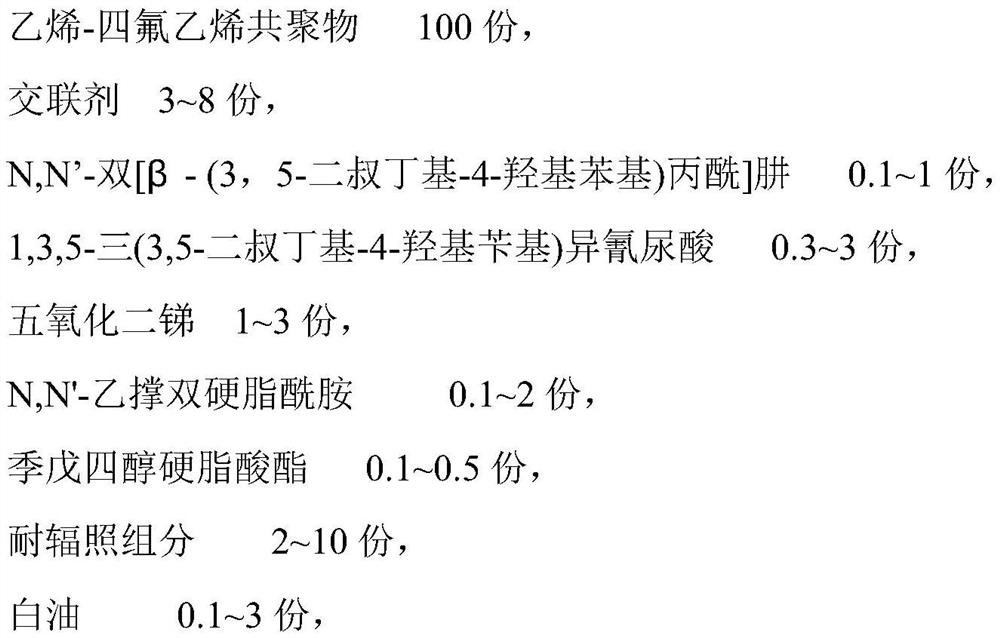

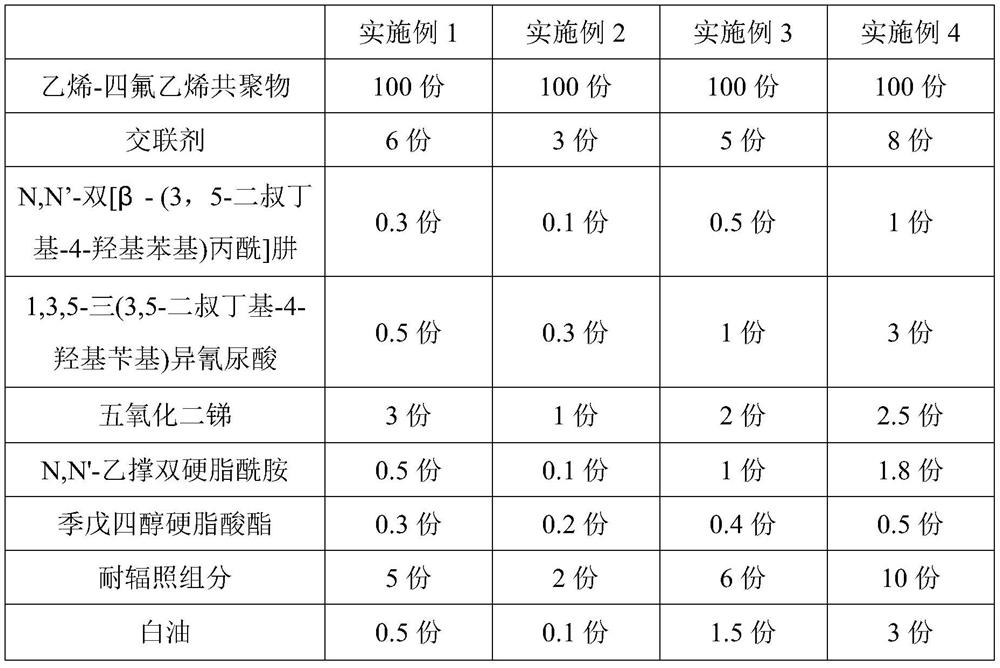

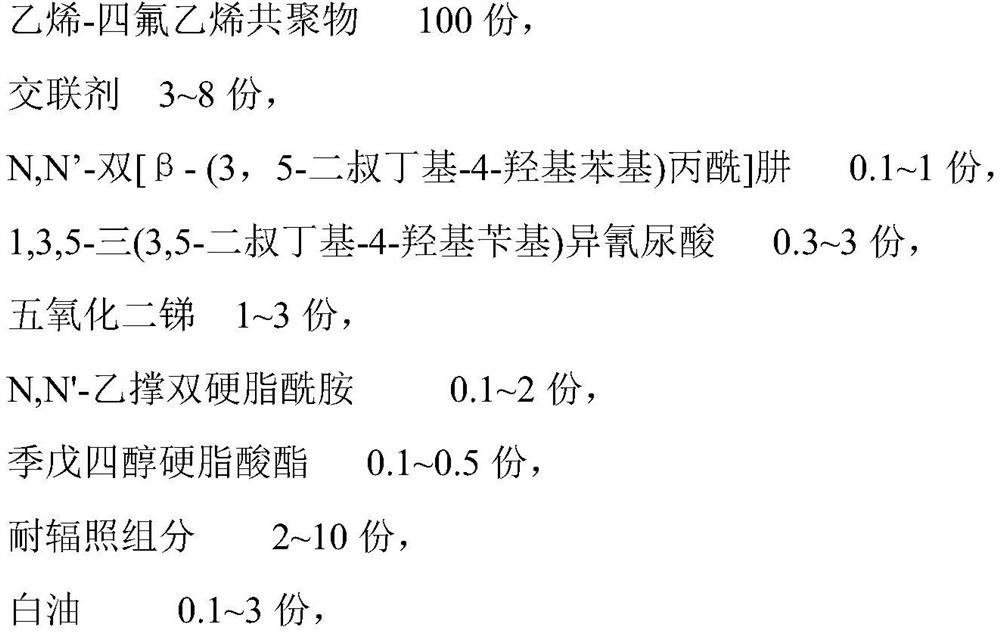

[0022] The composition of the radiation-resistant crosslinked ethylene-tetrafluoroethylene copolymer insulating material of the present invention is shown in Table 1, and the dosage of each component is by mass.

[0023] Radiation-resistant crosslinked ethylene-tetrafluoroethylene copolymer insulating material in Table 1 embodiment 1-4

[0024]

[0025] Among them, in Examples 1-4, the specific information of ethylene-tetrafluoroethylene copolymer, crosslinking agent and radiation-resistant components is shown in Table 2. The melt index of ethylene-tetrafluoroethylene copolymer is 6-40g / 10min.

[0026] The information of different substances in the embodiment 1-4 of table 2

[0027] Example 1 Example 2 Example 3 Example 4 Group X in the crosslinking agent Allyl Methallyl vinyl Allyl Polymerization degree of crosslinking agent n 3 5 2 1 The group R in the radiation-resistant component (CH 2 ) 2

(CH 2 ) 3

(CH 2 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com