Pressure cooking device

The technology of a cooking device and a cooking tank is applied in the fields of bioengineering equipment and food brewing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

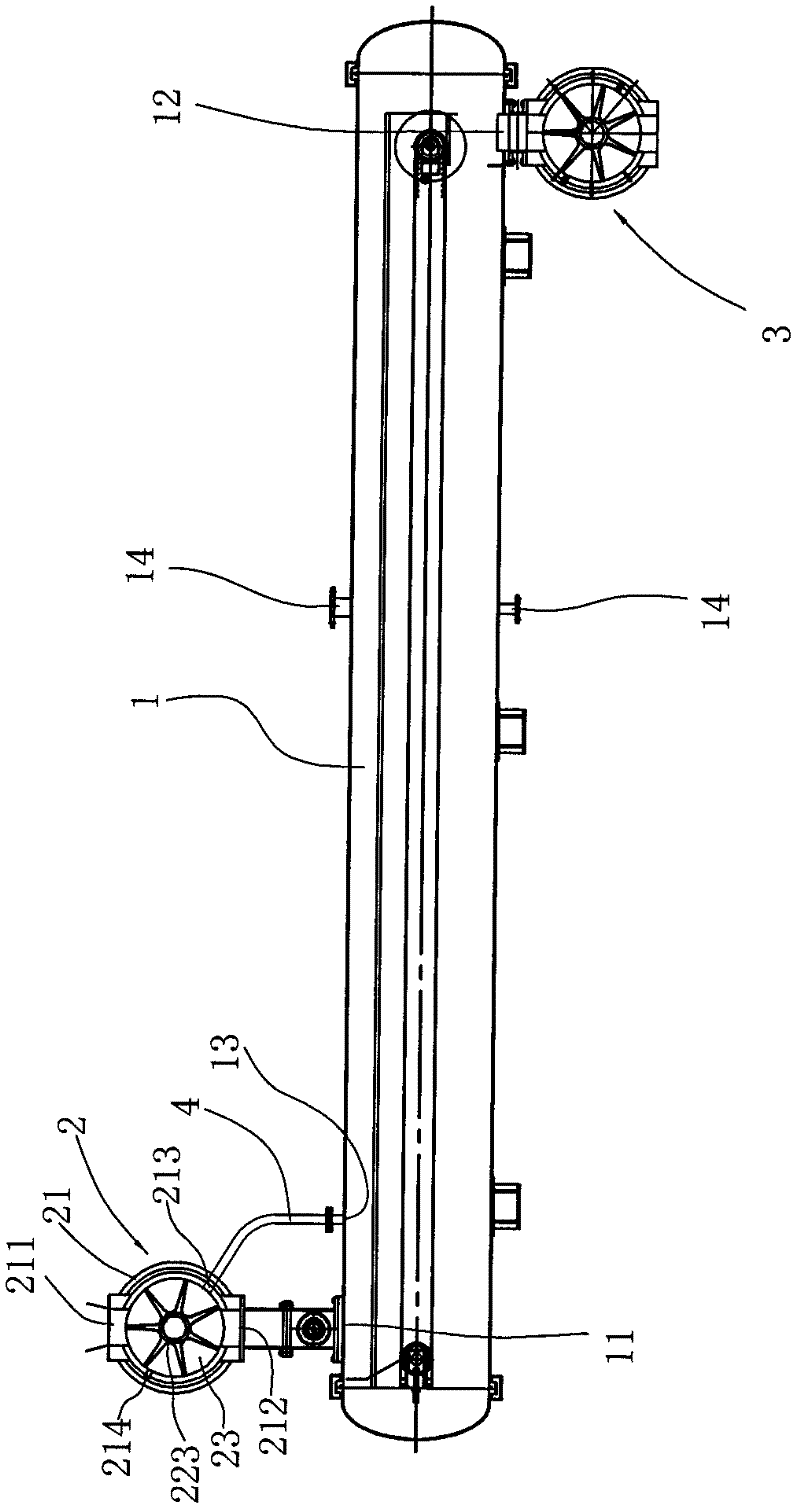

[0021] like Figure 1 to Figure 3 As shown, the pressure cooking device includes:

[0022] The cooking tank 1, the tank wall of the cooking tank is provided with a feed inlet 11, a feed outlet 12, an equal pressure hole 13 and a steam inlet 14 connected with an external steam pipeline. There are two steam inlets in this embodiment, which are respectively oppositely arranged on the tank wall of the cooking tank. Setting two steam inlets can make the materials in the cooking tank more evenly heated, increase the adjustability of the steam flow, and better ensure the stability of the temperature and pressure in the cooking tank.

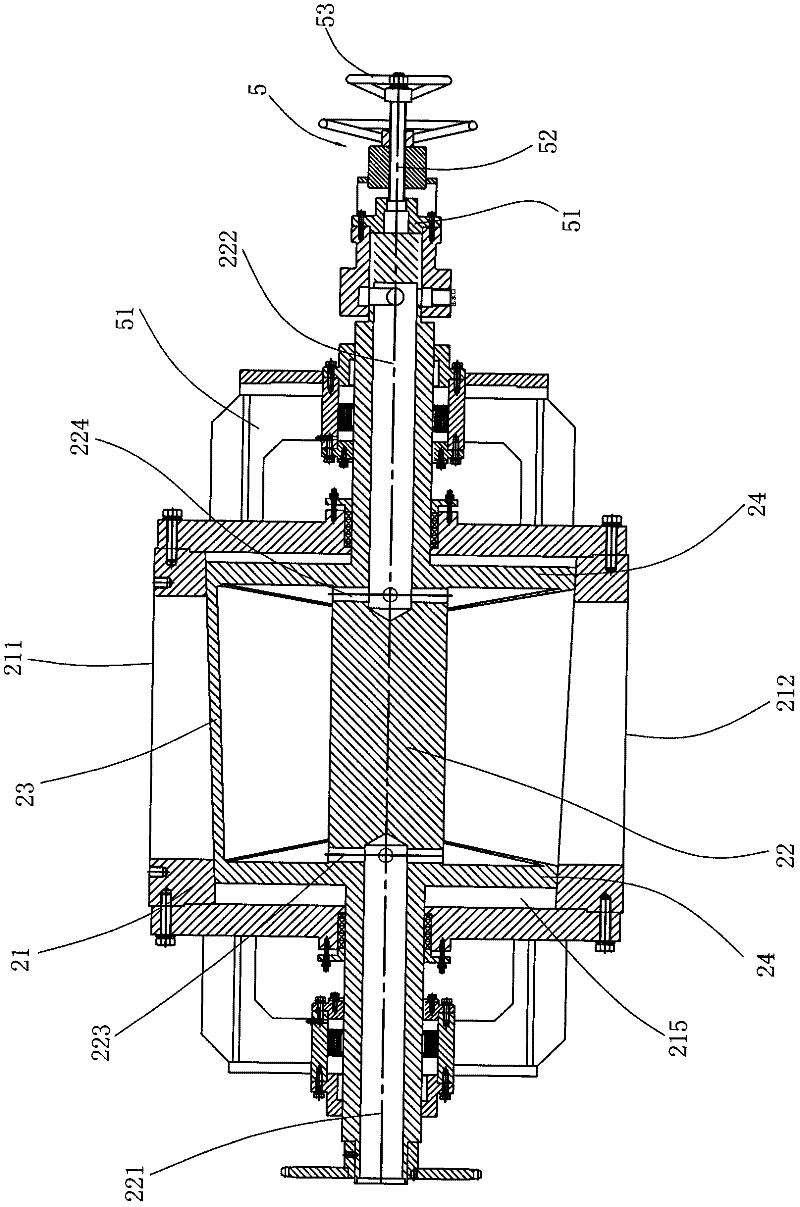

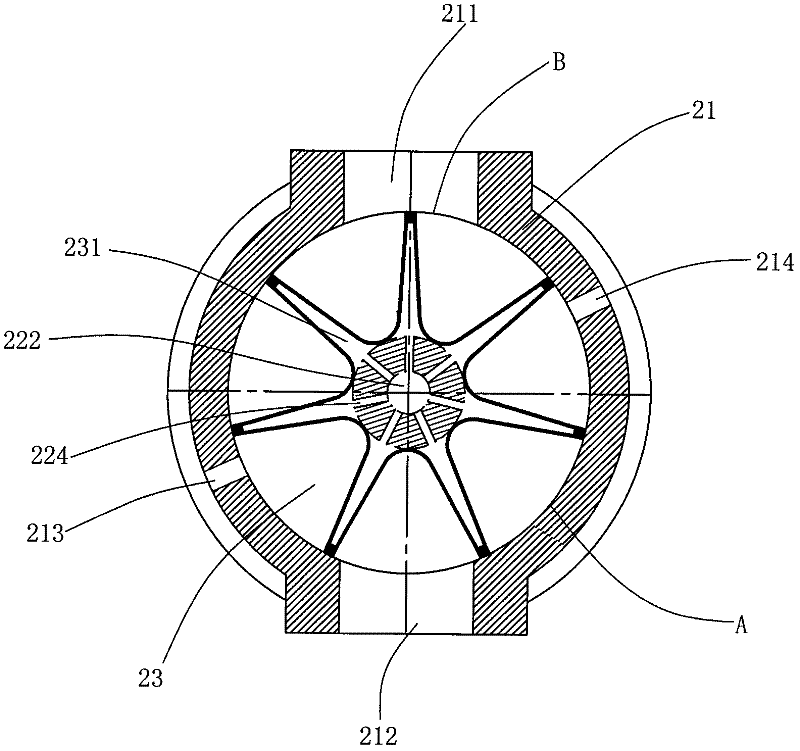

[0023] The feed valve 2 includes a valve body 21 , a valve stem 22 and a plurality of feed tanks 23 .

[0024] Wherein, the valve body 21 is provided with a material inlet 211 and a material outlet 212, the size of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com