Pretreatment method of magnetite

A processing method and magnetite technology, applied in grain processing and other directions, can solve problems such as environmental pollution and complex flotation process, and achieve the effects of environmental friendliness, simple processing method and good dissociation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

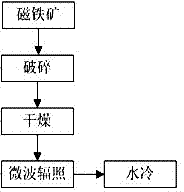

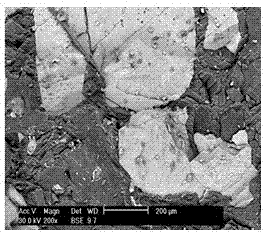

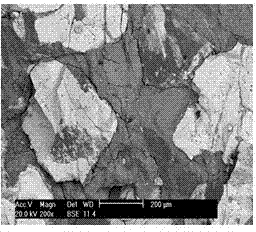

[0017] Example 1: see figure 1 , Weigh 50g of magnetite, crush it, the crushing particle size is 20mm, dry the crushed magnetite at 80°C for 30h, and then use a microwave heating device with a power of 1KW and a frequency of 2350MHZ to heat the sample. Microwave irradiation, the irradiation time is 25s, put it into the water under normal temperature condition and cool for 5min immediately after irradiation. from figure 2 with image 3 The comparison found that micro-cracks appeared on the surface of the ore after microwave irradiation.

[0018] Grinding the pretreated magnetite can make the ore particle size pass through the 200-mesh sieve to reach more than 80%. The magnetite after the ore grinding treatment is subjected to magnetic separation treatment, and the magnetic separation concentrate yield of the magnetite is increased from 44% to 72% when the raw ore is not treated; The grade of mineral products has increased by 6% compared with the original ore.

Embodiment 2

[0019] Example 2: see figure 1 , Weigh 500g of magnetite, crush it, the crushed particle size is 21mm, dry the crushed magnetite at 100°C for 40h, and then use a microwave heating device with a power of 3kW and a frequency of 2450MHz to process the sample. Microwave irradiation, the irradiation time is 60s, immediately put it into the water under the condition of normal temperature to cool for 8min after irradiation.

[0020] Grinding the pretreated magnetite can make the content of the ore pass through a 200-mesh sieve reach more than 80%. The magnetite after the ore grinding treatment is subjected to magnetic separation treatment, and the magnetic separation concentrate yield of the magnetite is increased from 44% to 72% when the raw ore is not treated; The grade of mineral products has increased by 8% compared with the original ore.

Embodiment 3

[0021] Example 3: see figure 1 , Weigh 300g of magnetite, crush it, the crushed particle size is 29mm, dry the crushed magnetite at 150°C for 60h, and then use a microwave heating device with a power of 6kW and a frequency of 2550MHz to process the sample. Microwave irradiation, the irradiation time is 70s, put it into the water under normal temperature condition to cool for 10min immediately after irradiation.

[0022] Grinding the pretreated magnetite can make the content of the ore pass through a 200-mesh sieve reach more than 80%. The magnetite after the ore grinding treatment is subjected to magnetic separation treatment, and the magnetic separation concentrate yield of the magnetite is increased from 44% to 72% when the raw ore is not treated; The grade of mineral products has increased by 8% compared with the original ore.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com