Automatic drilling machine

An automatic drilling machine and bed technology, applied in the direction of sawing machine, boring/drilling, drilling/drilling equipment, etc., can solve the problems of low automation, high cost, low efficiency, etc., and achieve the number and size of processing holes Flexible adjustment, the number and size of processing holes can be adjusted, and the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

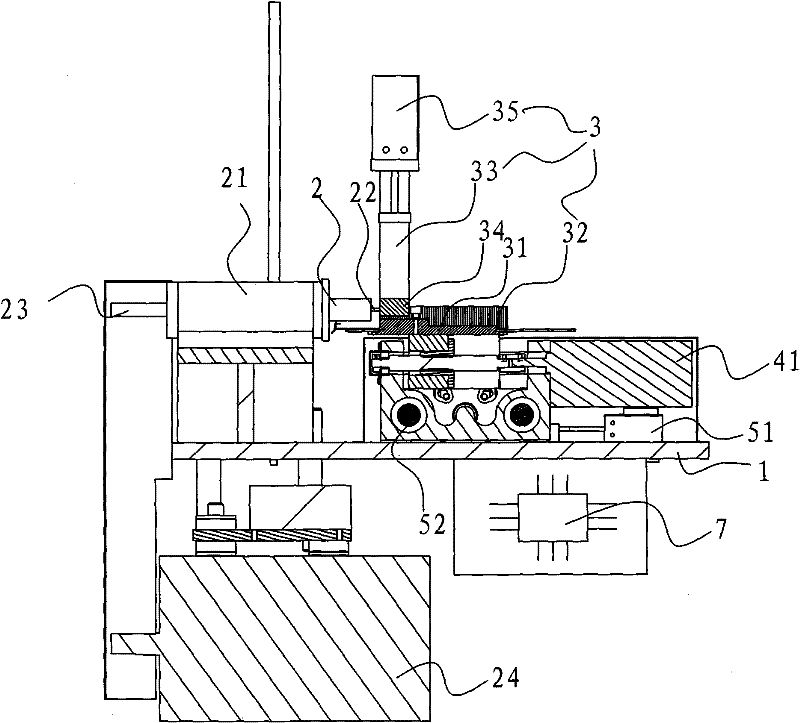

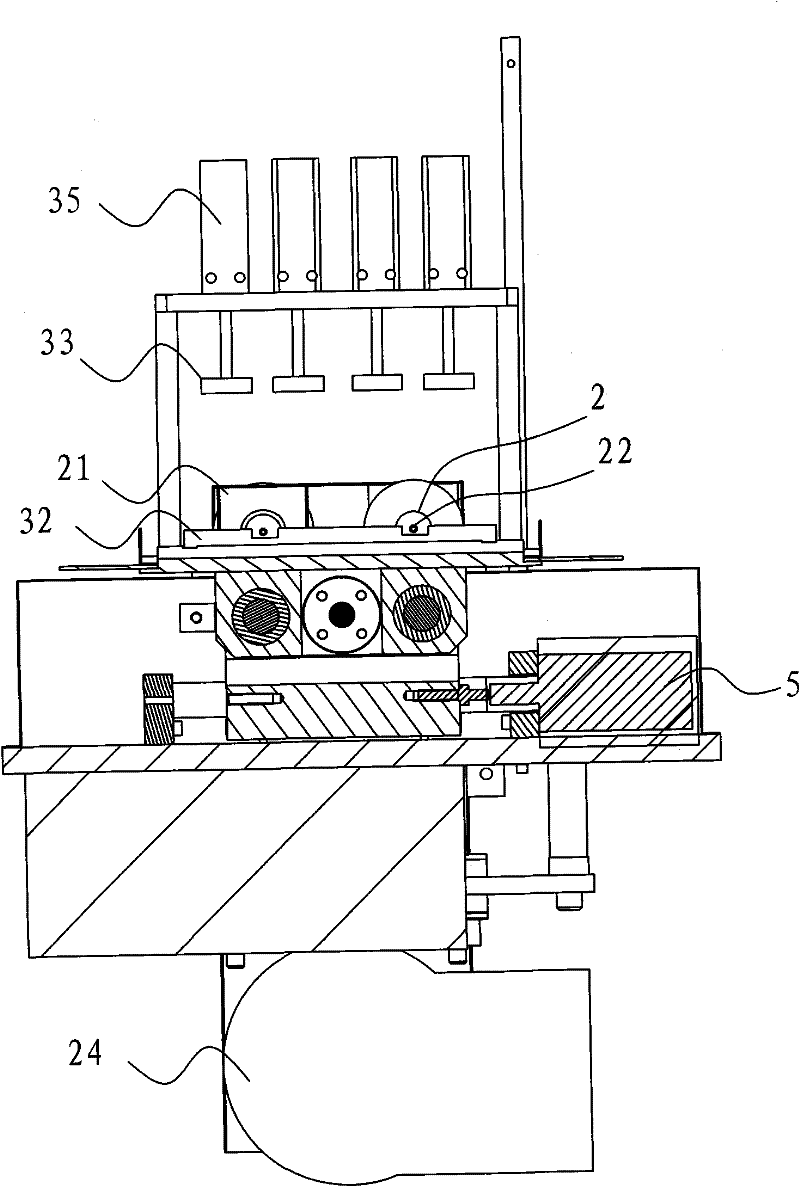

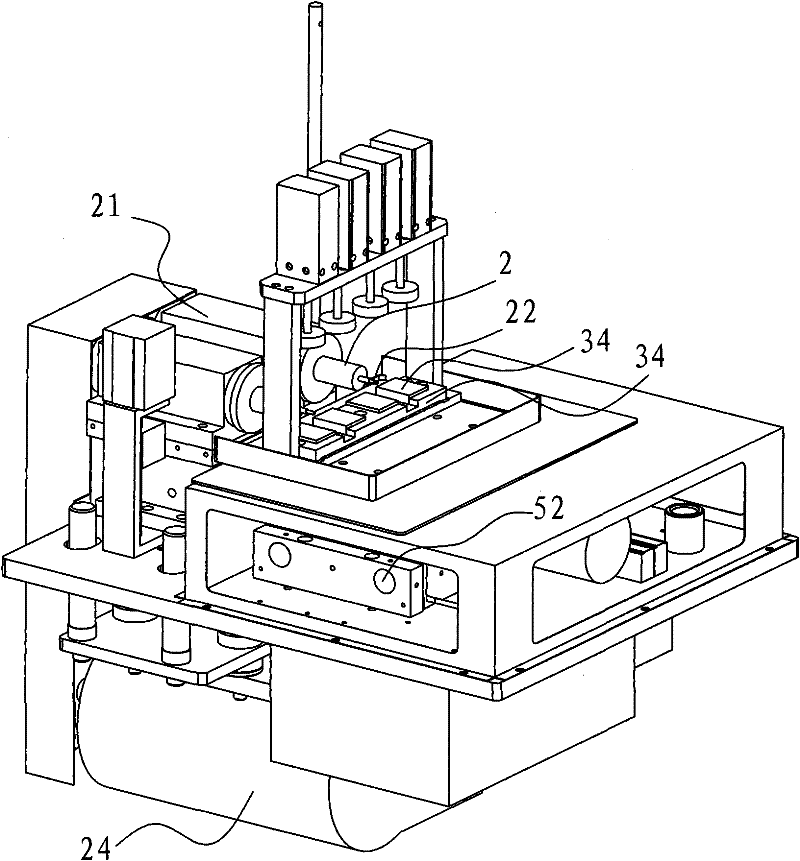

[0023] Such as figure 1 , figure 2 and image 3 As shown, an automatic drilling machine includes a bed 1, a main shaft 2, a main shaft transmission device, a workpiece clamping device 3, a left and right moving device 5, a vertical lifting device 6 and a tool feeding device.

[0024] There are two main shafts 2 and their axes are placed horizontally. The two main shafts 2 are placed in the provided main shaft box 21. A section of the main shaft box 21 is provided with a power input shaft 23, and the power input shaft 23 extends out of the main shaft box 21. A belt pulley is installed, and is connected with the belt pulley on the output shaft of the AC motor 24 of the main shaft transmission device through a belt transmission. A gear system is arranged in the main shaft box 21. The gear system connects the main shaft 1 with the power input shaft 23 transmission, and the main shaft 2 extends A drill chuck is installed on the end of the spindle box 21, and a drill bit 22 of ch...

Embodiment 2

[0031]The rest are the same as in Embodiment 1, except that there is only one spindle 2, so one workpiece 34 can be processed each time.

Embodiment 3

[0033] The rest are the same as in Embodiment 1, the difference is that there are four main shafts 2, all of which are connected to the power input shaft 23 through the main shaft box 21, and four grooves matching the external dimensions of the workpiece 34 are processed on the clamp base 32, so Four workpieces can be processed at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com