Sliding bearing body structure of large-caliber chemical circulating double-suction pump

A technology of chemical circulation and sliding bearings, which is applied to parts, pumps and pump components of pumping devices for elastic fluids, and can solve the problems of inconvenient replacement of oil seals, large swinging range of oil throwing rings, and large vibrations, etc., to achieve Avoid oil and gas mixing, good lubricating effect, and large load bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

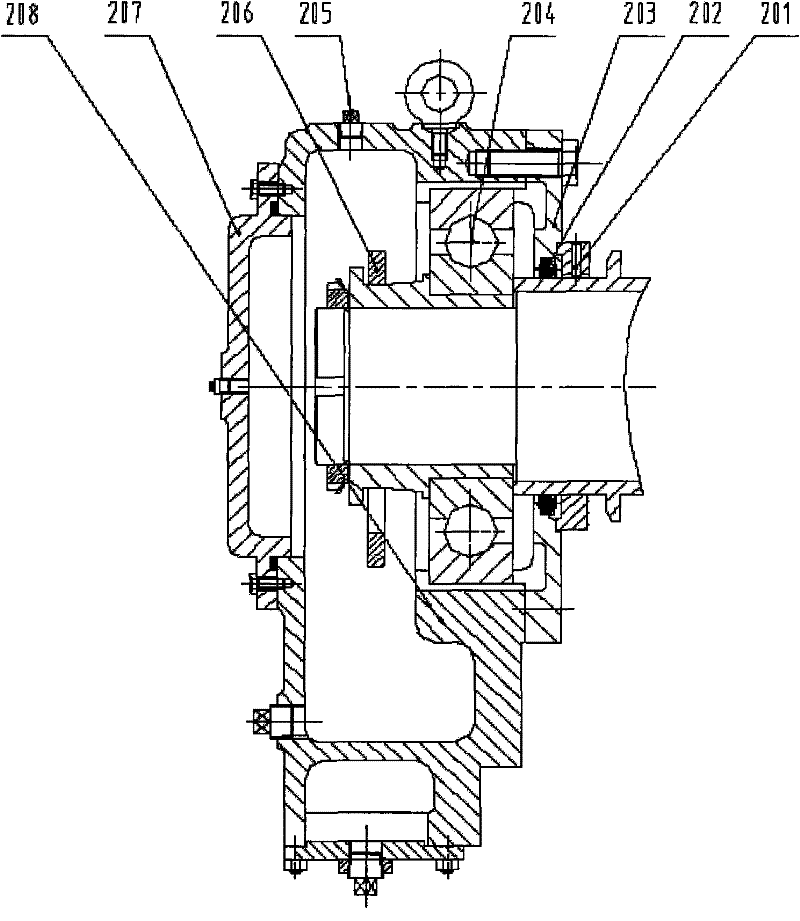

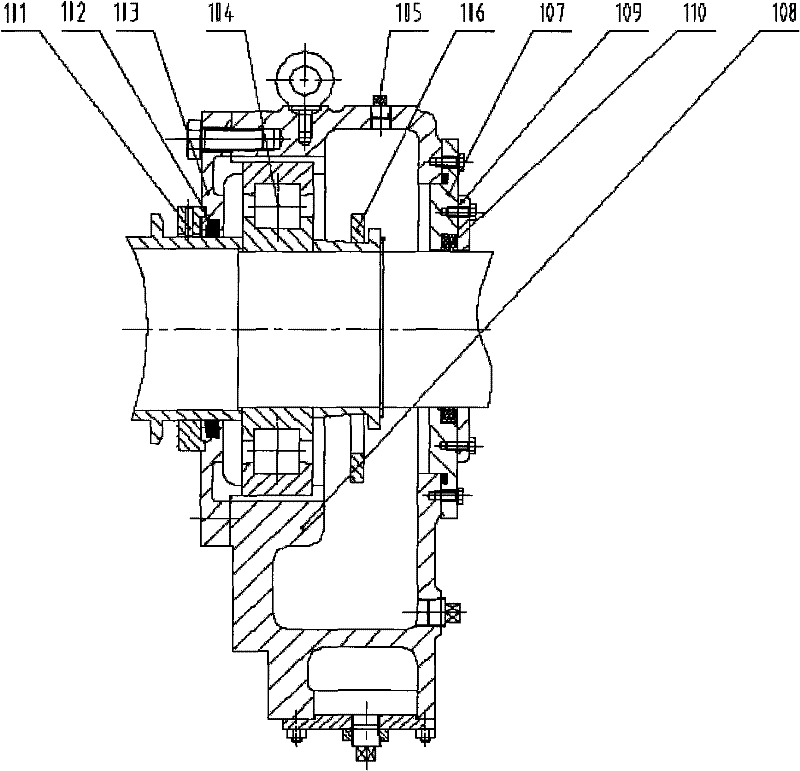

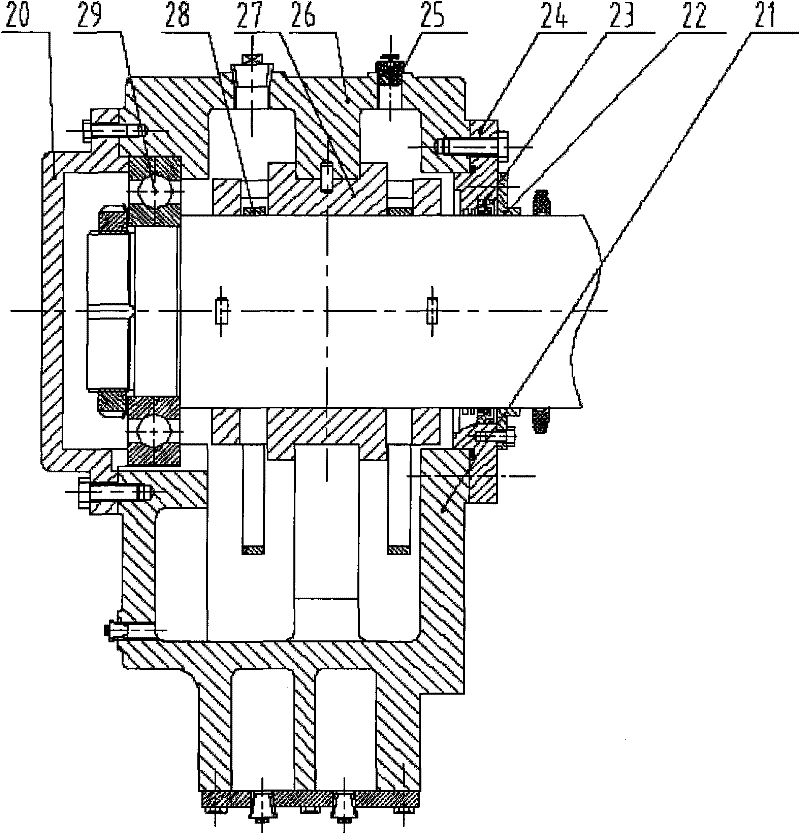

[0019] Depend on image 3 , Figure 4 It can be seen that the present invention includes: the tail end bearing part and the driving end bearing part; the tail end bearing part includes: the tail end bearing seat 21, the tail end half-type oil seal cover plate 22, the tail end half-type oil seal 23, the tail end bearing seat End bearing end cover 24, tail end automatic air release valve 25, tail end bearing cover 26, tail end sliding bearing 27, tail end double oil throwing ring 28, rolling bearing 29 and bearing tail cover 20; the upper end of tail end bearing seat 21 and The lower end of the tail end bearing cover 26 is fixedly connected by bolts to form the tail end bearing chamber; the rolling bearing 29 is arranged at the left end in the tail end bearing chamber, and the tail end sliding bearing 27 is arranged at the right end in the tail e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com