Grease composition

A grease composition and composition technology, applied in the field of grease compositions for lubricating rolling bearings, to achieve good mechanical strength and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

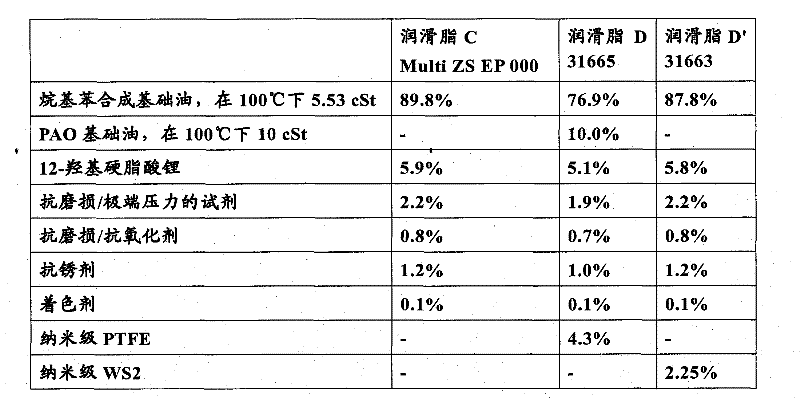

Embodiment 1

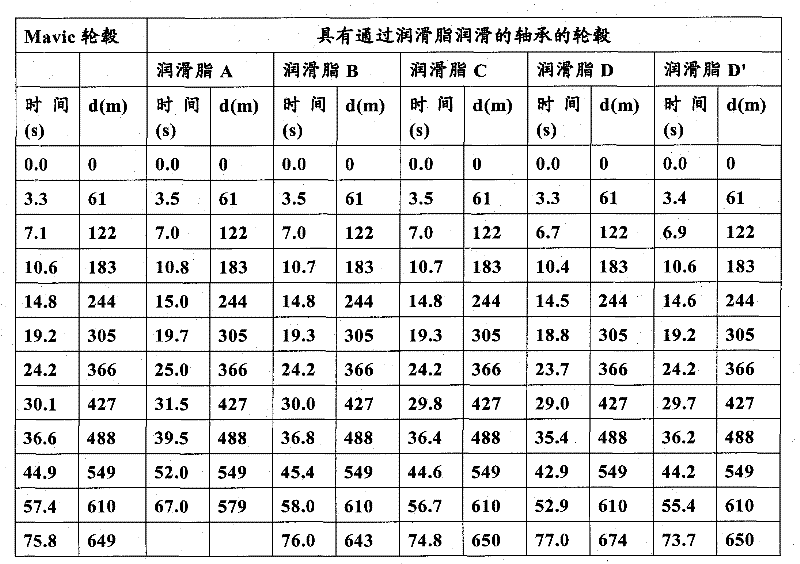

[0142] We have compared the performance of bicycle hubs comprising bearings lubricated with different greases to Mavic hubs with ball bearings, such as those mounted on Mavis Cosmic type bicycle wheels, considering the upmarket consumer market in this field. The lubricated bearing hub used is of the type described in patent application EP 1 719 641 .

[0143] The benefits of the rolling bearing system Mavic and the lubricated bearing system are determined according to the test platform:

[0144] - Drive the bicycle wheel with the hub to be tested (hub with Mavic ball bearings or hub with bearings lubricated with different greases) with an electric motor at an initial speed of 70 km / h followed by 50 km / h during a 5 minute heating period .

[0145] - A load of 50 kg is applied to it throughout the duration of the test.

[0146] - At an initial instant, the power to the motor is switched off, and the distance traveled before stopping (or locking) is subsequently measured.

[0...

Embodiment 2

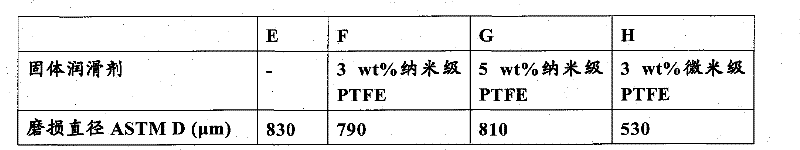

[0167] Example 2: Effect of base oil

[0168] The same polytetrafluoroethylene nanoparticles as used in grease D according to the invention were added to grease (E) based on synthetic base oils of the PAO type, grease E was made with the same lithium metal soap (12-hydroxystearic acid Lithium) thickens.

[0169] An initial PAO+lithium grease (Grease E) was mixed with Grease E (Grease F, G, respectively) containing 3wt% and 5wt% nano-sized PTFE respectively and with 3wt% Grease E (Grease H) of micron PTFE was subjected to 4-bead test ASTM D2266 for anti-wear performance comparison.

[0170] The results are shown in Table 3 below:

[0171]

[0172] Table 3: Anti-wear properties

[0173] Greases E and F, G have the same level of performance: the addition of nanoscale PTFE to the PAO-based grease did not provide a significant improvement in anti-wear properties. At comparable amounts, micron-sized PTFE provides greater gains in terms of wear.

[0174] Without wishing to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com