Process for pretreating manure in farm

A pretreatment and farm technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of not being able to prevent damage well, complex processes, etc., to facilitate classification and treatment, improve survival rate, and facilitate temperature Effects of Control and Feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

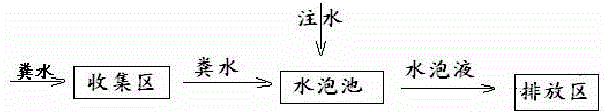

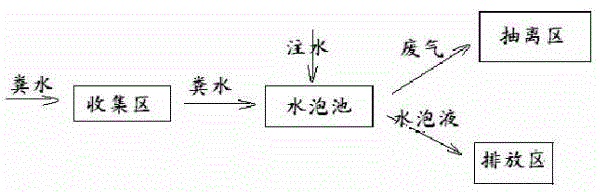

[0030] Take the manure treatment of pig farms as an example.

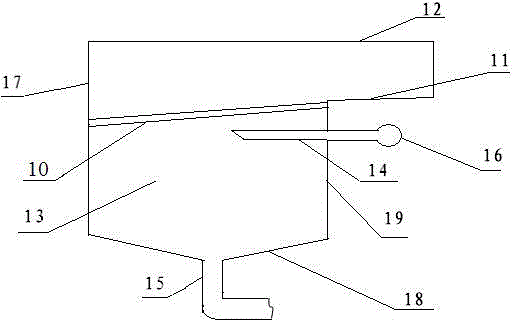

[0031] Pig house manure is treated by the pretreatment system of the present invention. The pretreatment system is set in the breeding house. The pretreatment system includes a manure collection area A, an exhaust gas extraction area B, a blister liquid discharge area C, and a blister area D , wherein, the manure collection area A includes a slatted floor 10 and a cement floor 11 connected to the slatted floor, and the slatted floor 10 and the cemented floor 11 are laid obliquely respectively; the blister area D includes a The blister pool 13 directly below the entire slatted floor 10; the blister liquid discharge area C includes a funnel-shaped pool bottom 18 located at the bottom of the blister pool and a discharge pipeline with a controllable valve installed below the funnel-shaped pool bottom 18 15. The waste gas extraction area B includes the air extraction sub-pipe 14 arranged on the wall 19 of the bubble poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com