Stirring head capable of enhancing mechanical property of stirring friction connecting area

A friction stirring and joining zone technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as unreasonable structure design of the stirring head and prone to welding defects, so as to improve the performance of the joining zone and control the joining zone The effect of thickness reduction and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

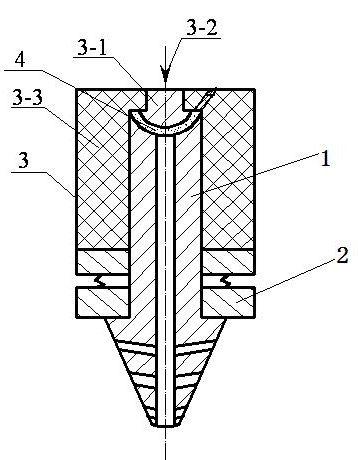

[0019] like Figure 1-3 shown.

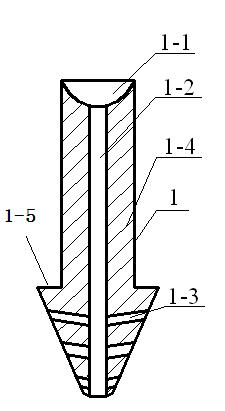

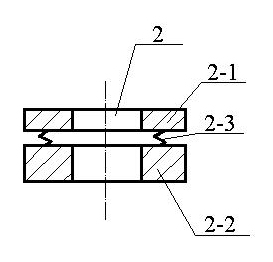

[0020] A stirring head that can enhance the mechanical properties of the friction stir connection area, which is mainly composed of an integral stirring needle 1, a detachable shaft shoulder 2 and a clamping handle 3, such as figure 1 As shown in the figure, the material of the detachable shoulder 2 can be made of well-known ordinary steel, and the integral stirring needle 1 can choose tool steel and tungsten-rhenium alloy according to different processing materials. 45# steel can be selected, and cemented carbide steel can be selected for extrusion piston 3-1. The integral stirring needle 1 is formed by integrally connecting a cylinder 1-4 and a conical head 1-5, and a storage chamber 1-1 for filling the filler 4 is provided at the upper end of the cylinder 1-4, The filler 4 can be made of wear-resistant and corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com