Polypropylene film capable of resisting fog and preparation method thereof

A polypropylene film, polypropylene technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the anti-fog effect of poor durability, easy to be washed or wiped off, anti-fog performance Can not meet the use requirements and other problems, to achieve the effect of good transparency, excellent anti-fog effect, and conducive to manufacturing and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

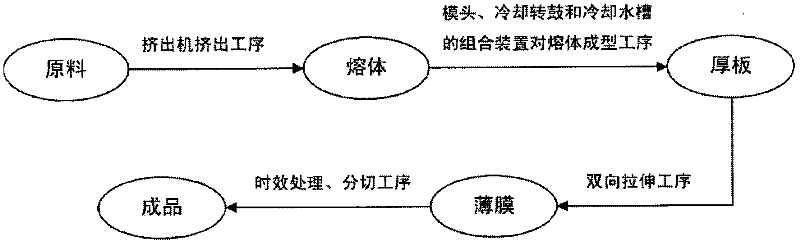

[0040] A kind of preparation method of the polypropylene film with anti-fog performance of the present invention, adopts following process step:

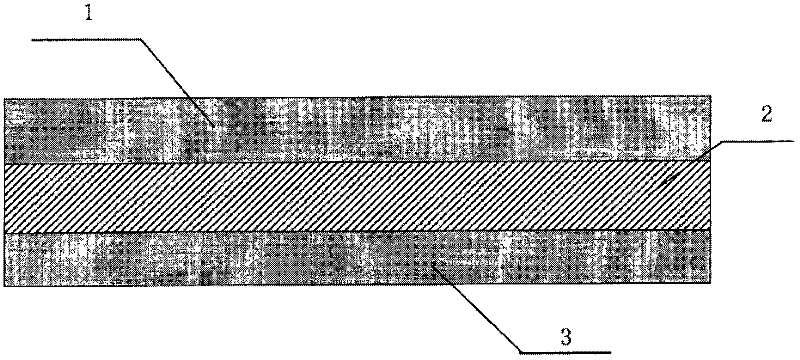

[0041] The polypropylene functional film that can prevent water vapor from forming fog on the film surface and affecting transparency of the present invention includes a co-extruded upper surface layer 1 (functional layer), a core layer 2 (substrate layer), and a lower surface layer 3 (functional layer). layer), when making this film, the upper surface layer, the core layer and the lower surface layer are co-extruded composite structures, and these three layers constitute the most basic three-layer structure of the film of the present invention. The total thickness of the film is 25 μm, the thickness of the upper surface layer is 1.1 μm, and the thickness of the lower surface layer is 1.1 μm.

[0042] 1. Drying treatment of raw materials: Since the degree of degradation of the stretched film and whether there are bubbles on the film...

Embodiment 2

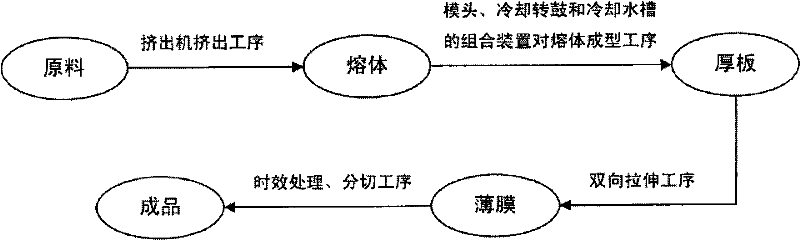

[0065] A kind of preparation method of the polypropylene film with anti-fog performance of the present invention, adopts following process step:

[0066] When the present invention manufactures the film, the upper surface layer, the core layer and the lower surface layer are co-extruded composite structures, and these three layers constitute the most basic three-layer structure of the film of the present invention. The total thickness of the film is 30 μm, and the thickness of the upper surface layer and the lower surface layer is 1.1 μm.

[0067] 1. Raw material drying treatment: Since the degree of degradation of the stretched film and whether there are bubbles on the film are related to the moisture content in the raw material, the advanced BOPP production line should also dry the raw material at 80°C to 110°C before extrusion. Drying time 2 ~ 4hrs. Especially in the production of co-extruded films, the raw materials of the core layer contain many hygroscopic additives, an...

Embodiment 3

[0093] A kind of preparation method of the polypropylene film with anti-fog performance of the present invention, adopts following process steps:

[0094] When the present invention manufactures the film, the upper surface layer, the core layer and the lower surface layer are co-extruded composite structures, and these three layers constitute the most basic three-layer structure of the film of the present invention. The total thickness of the film is 35 μm, and the thickness of the upper surface layer and the lower surface layer is 1.1 μm.

[0095] 1. Raw material drying treatment:

[0096] Since the degree of degradation of the stretched film and whether there are bubbles on the film are related to the moisture content in the raw material, the advanced BOPP production line should also dry the raw material at 80℃~110℃ before extrusion, and the drying time is 2~4hrs. Especially in the production of co-extruded films, the raw materials of the core layer contain many hygroscopic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Screw diameter | aaaaa | aaaaa |

| Screw diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com