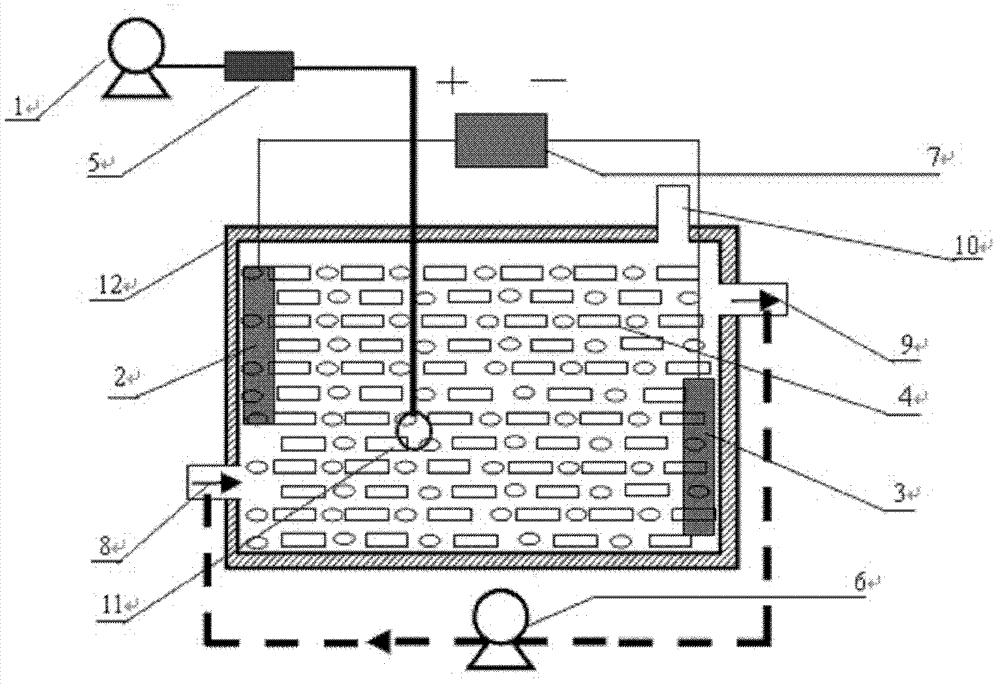

Bioelectrochemical denitriding reactor and application method thereof

A bioelectrochemical and reactor technology, applied in the field of wastewater biological treatment, can solve the problems of large energy consumption, addition, slow start, etc., and achieve the effect of large current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

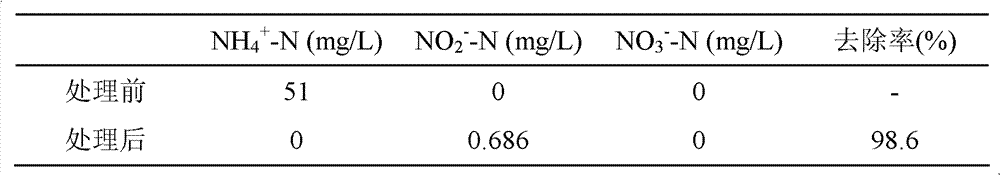

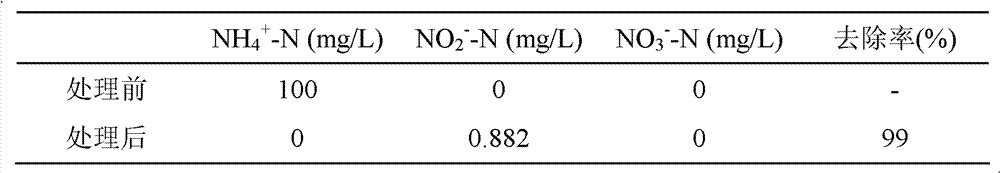

Embodiment 1

[0032] (1) Electrode Biofilm Acclimatization

[0033] Ammonia oxidation biofilm hanging film: put a 8cmx15cm carbon felt electrode into an independent reactor, inoculate aerobic nitrification sludge, maintain low dissolved oxygen, and dilute a certain concentration of landfill leachate, the initial ammonia nitrogen concentration is 105mg / L, and add 2.0g / L NaHCO 3 , detect changes in the concentration of three nitrogens (ammonia nitrogen, nitrite nitrogen, nitrate nitrogen) every day. When the ammonia nitrogen consumption reaches 5-10 mg / L, change the liquid, reconfigure the ammonia nitrogen wastewater, and add NaHCO 3 , run continuously for 4 weeks until the nitrosation rate reaches 90%, and the ammonium oxidation treatment load stabilizes at 0.1-0.12kg / (m 3 When d), it indicates that the dominant ammonia oxidizing bacteria group has formed, and the ammonia oxidizing biofilm has been established.

[0034] Denitrification biofilm hanging film: put a 8cmx15cm carbon felt ele...

Embodiment 2

[0041] Example 2: The reactor and denitrification method constructed in this example are basically the same as Example 1, except that the initial ammonia nitrogen concentration in the wastewater is 100 mg / L, and the water quality after 3 days of treatment is shown in Table 2.

[0042] The water quality after the treatment of table 2 embodiment 2

[0043]

Embodiment 3

[0044] Example 3: The reactor and denitrification method constructed in this example are basically the same as Example 1, except that the initial ammonia nitrogen concentration in the wastewater is 150 mg / L, and the water quality after 5 days of treatment is shown in Table 3.

[0045] The water quality after the treatment of table 3 embodiment 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com