Low-radiation composite vacuum phase-change thermal insulating energy-saving wall board

A phase-change thermal insulation material and low-radiation technology, applied in covering/lining, layered products, buildings, etc., to reduce costs, improve thermal performance, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

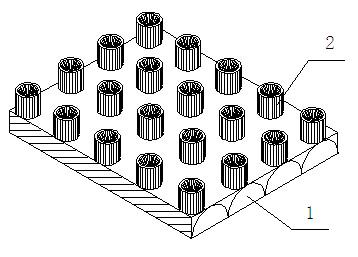

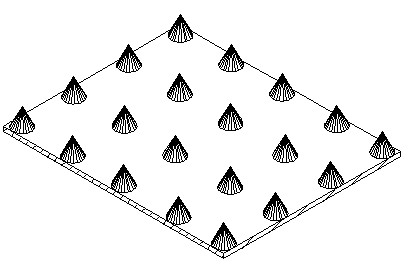

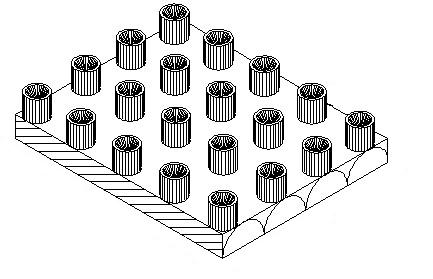

[0023] It includes a wallboard and a phase-change thermal insulation body. The existing wallboard can be used for the wall body. A phase-change thermal insulation body 3 is arranged on the wall body 1. The phase-change thermal insulation body 3 is cylindrical, conical or cylindrical. Phase-change thermal insulation material is housed in the phase-change thermal insulation body 3 . The phase change insulation material is paraffin. The phase-change thermal insulation body 3 is fixed between a single-sided wall or a double-sided wall. The phase-change thermal insulation body 3 is single-layer or multi-layer, or a mixture of phase-change thermal insulation bodies of different thermal insulation materials. Low radiation complex

[0024] The installation method of vacuum phase change thermal insulation and energy-saving wall panels is such as using phase change materials to absorb energy at night in summer and heat during the day in winter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com