Construction method for automobile adit and slant chute

A construction method and the technology of sliding wells, which are applied in shaft lining, underground chambers, shaft equipment, etc., can solve problems such as poor roads, irregular shapes of openings and inner walls, and difficulty in vertical transportation, so as to avoid the loss of secondary rework , Reduction of reverse transportation and vertical transportation, simple and feasible construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

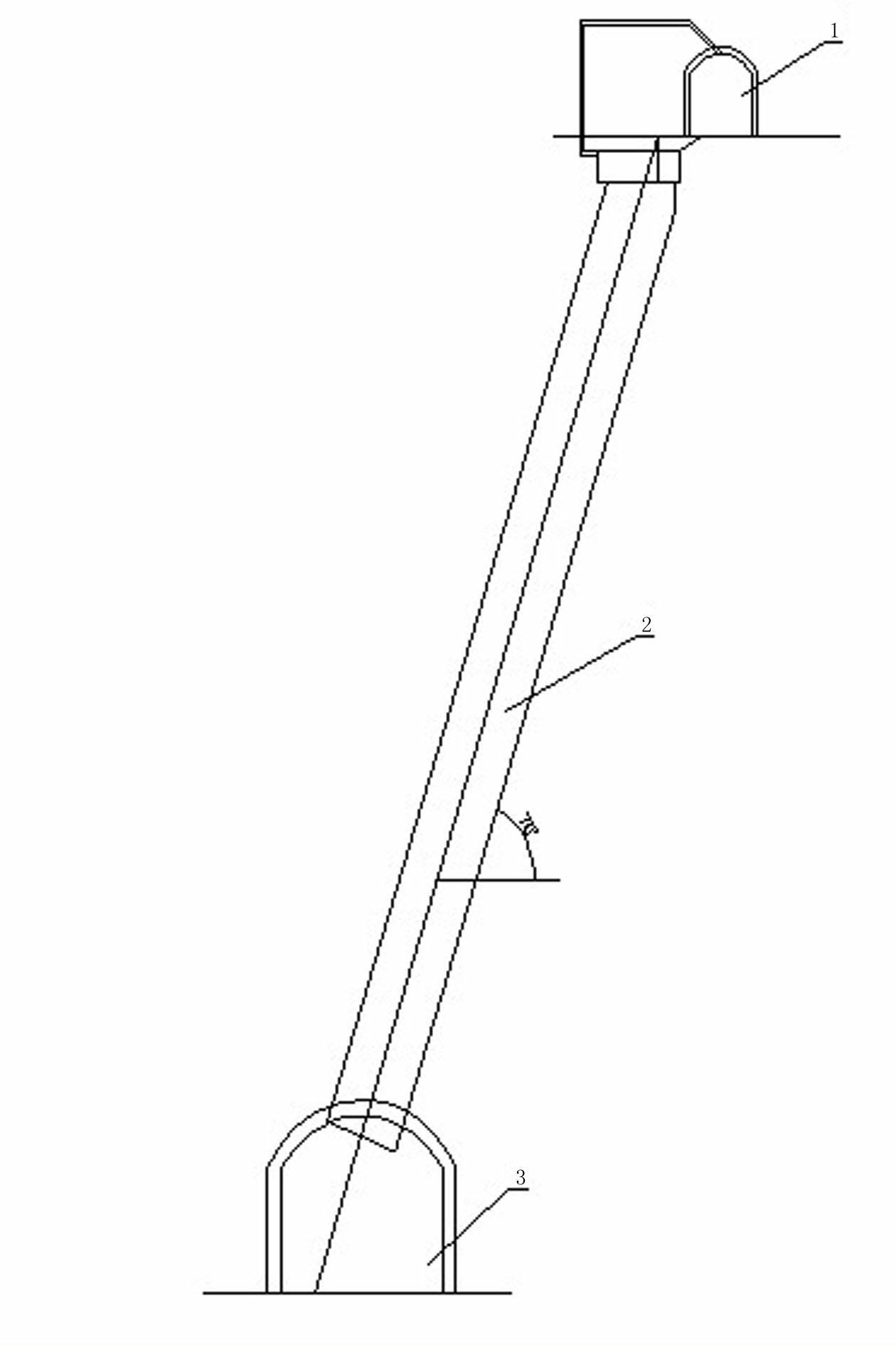

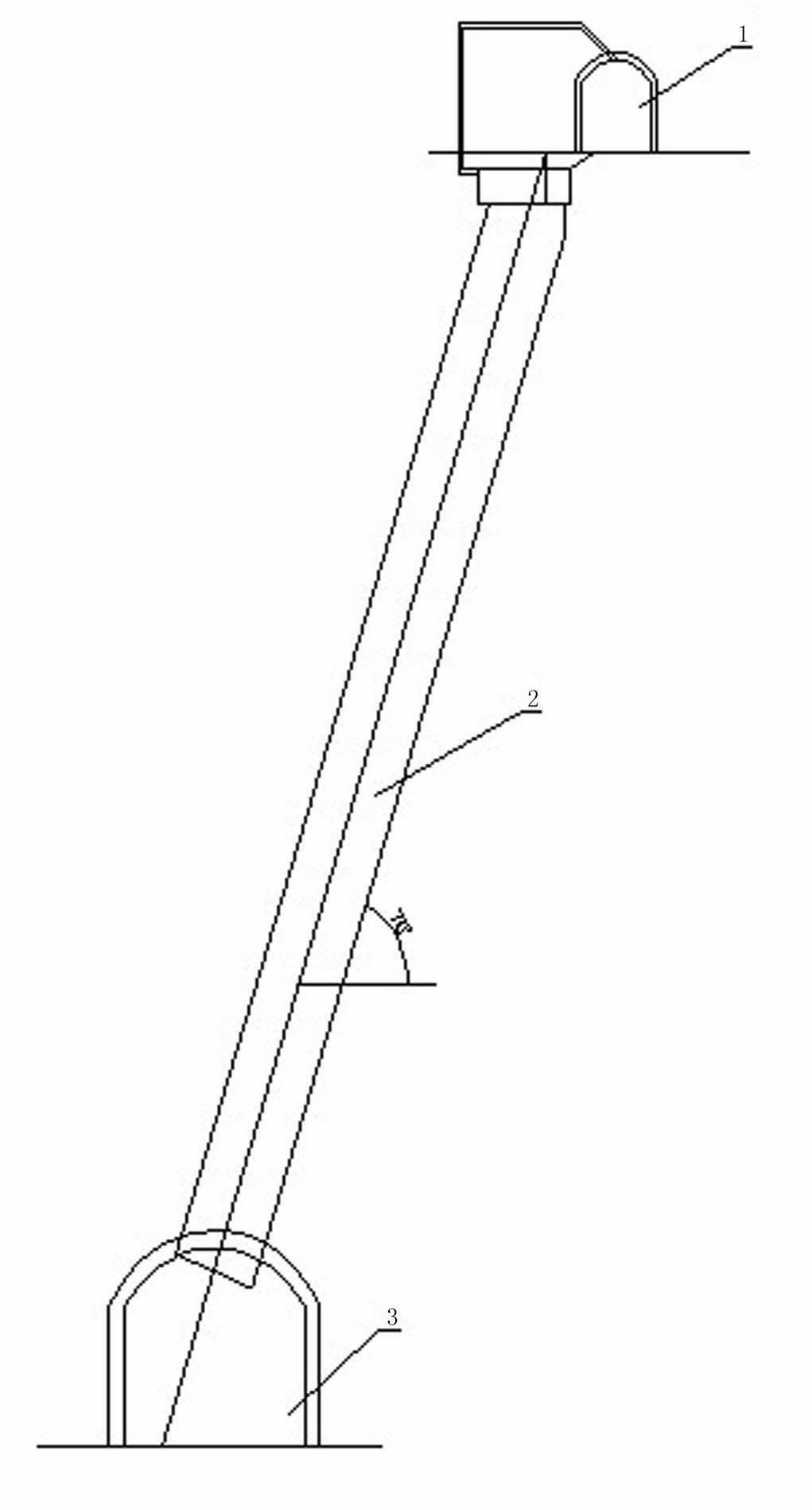

[0023] Such as figure 1 Shown, the 70-degree inclined chute construction method of automobile adit of the present invention comprises the following steps:

[0024] a. In order to ensure the safety of the construction, firstly, spray grout with a thickness of 50 mm on the inner walls of the inclined chute 2 and chamber 3 after blasting to prevent falling stones from hurting people;

[0025] b. then carry out the pouring construction of the base plate and the vertical wall connected to the base plate at the bottom of the inclined chute 2;

[0026] c. According to the radial dimension of the inclined chute 2, support the assembled arc template in the inclined chute 2 along the center point of the bottom plate. , use the total station to locate the radial and horizontal positioning line of the bottom plate, use the ink fountain to pop up the radial positioning line on the bottom plate, and then use the total station to rotate vertically upward by 70 degrees to locate the central ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com