Cylindrical-cavity type solar heat absorber with internally-convex bottom surface

A solar heat absorber and heat absorber technology, which is applied to solar heat collectors, solar heat collectors using working fluids, solar heat energy, etc., can solve the problem that metal tubes are difficult to cover the entire bottom surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

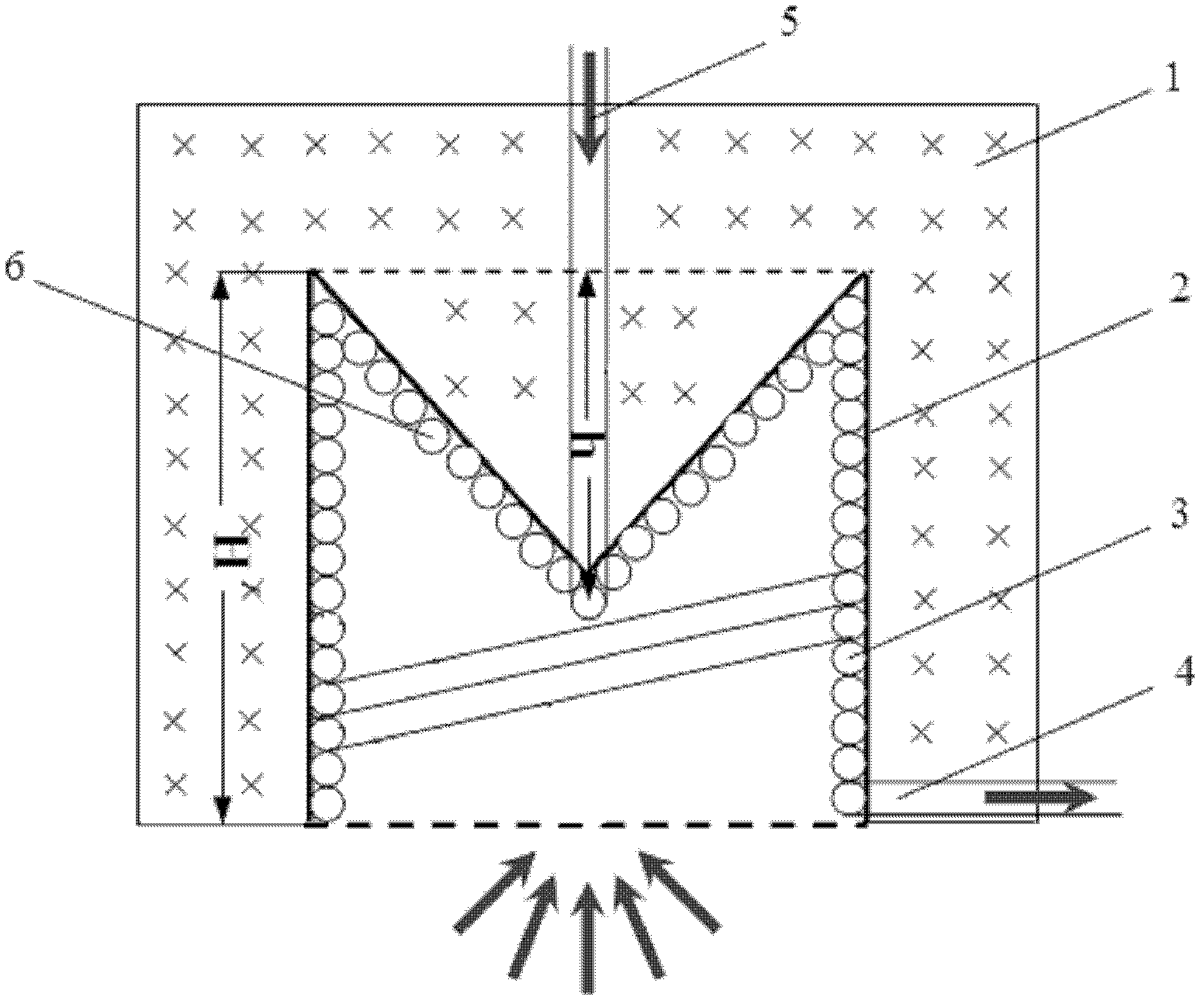

[0009] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a cylindrical cavity-type solar heat absorber with an inner convex bottom surface of this embodiment includes a slag wool insulation layer 1, a heat absorber shell 2, a side coil 3 of the heat absorber, and a working medium outlet pipe 4 , the working medium inlet pipe 5 and the inner convex segment coil 6 on the bottom surface of the heat absorber. The bottom surface of the heat absorber shell 2 has a V-shaped structure, the side coil 3 of the heat absorber is wound on the side inner wall of the heat absorber shell 2, and the coil 6 of the convex section in the bottom surface of the heat absorber is wound on the On the bottom surface of the heat absorber shell 2, the inlet end of the coil pipe 3 on the side of the heat absorber communicates with the outlet end of the raised section coil pipe 6 in the bottom surface of the heat absorber, and on the outer surface of the heat absorber shell ...

specific Embodiment approach 2

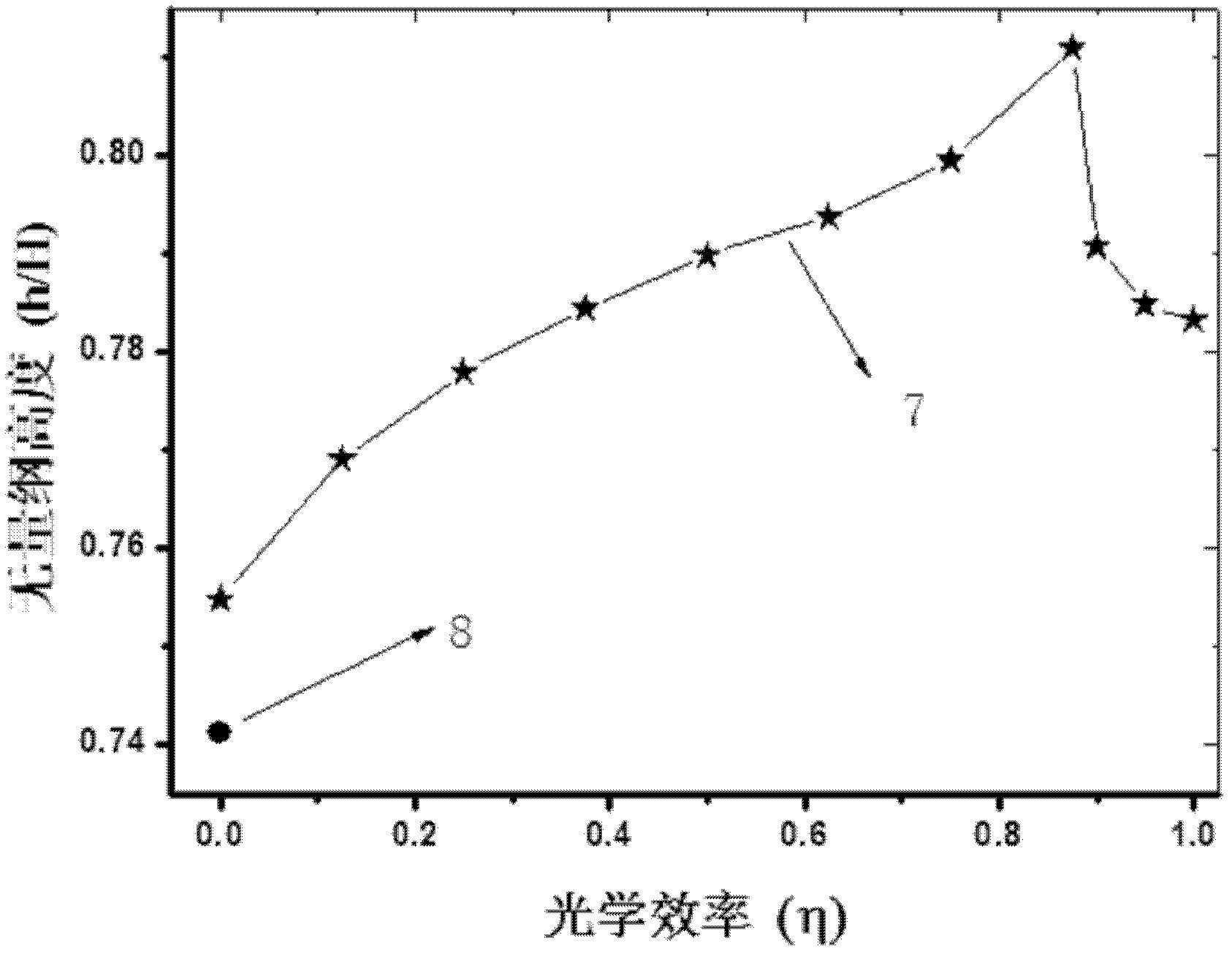

[0010] Specific implementation mode two: combination figure 1 The present embodiment will be described. The ratio of the bottom surface protrusion height h of the heat absorber case 2 to the height H of the heat absorber case 2 of the present embodiment is 0.75 to 1. With such arrangement, the optical efficiency of the solar heat absorber varies with the dimensionless height h / H of the protrusion inside the bottom coil tube. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

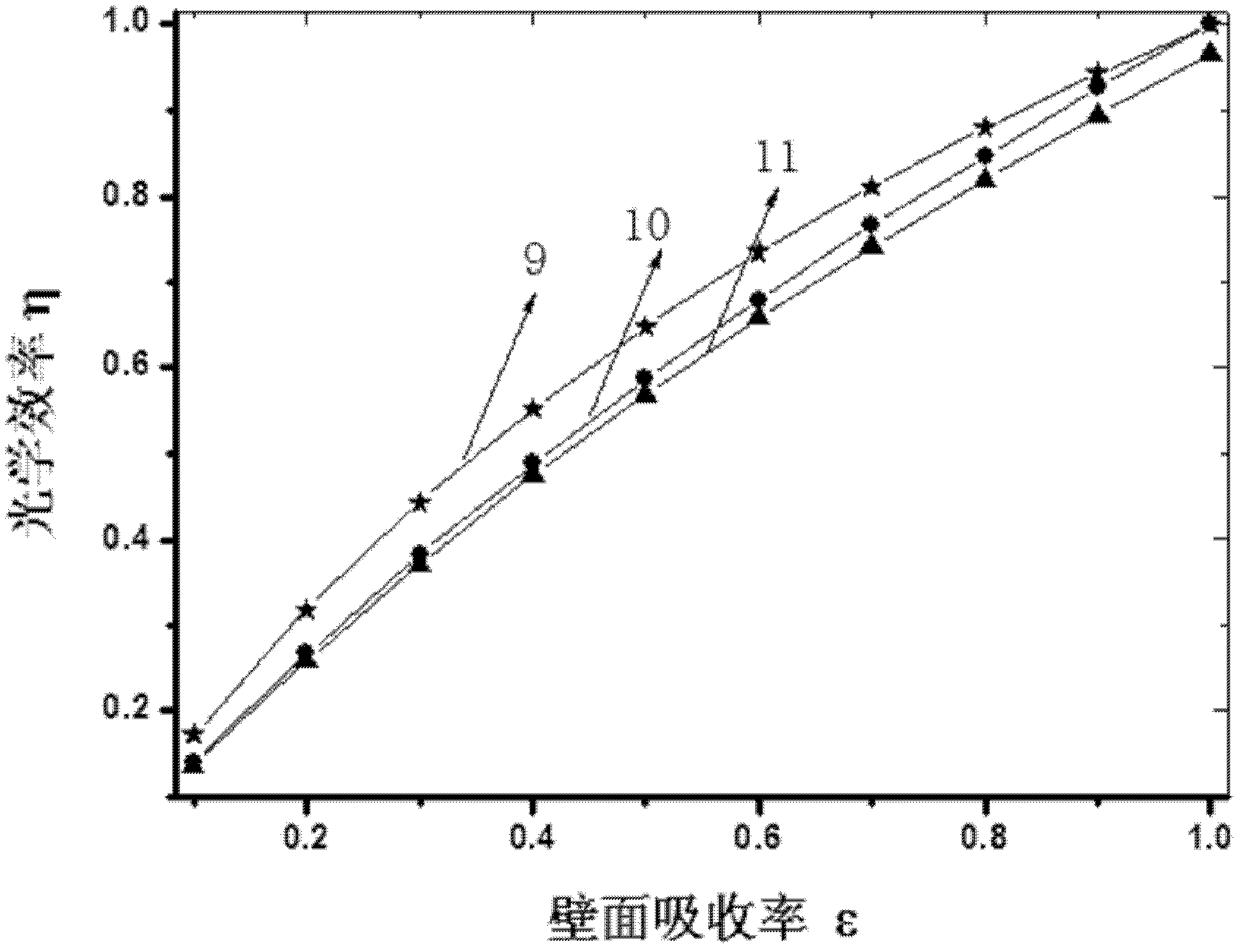

[0011] Specific implementation mode three: combination figure 1 The present embodiment will be described. The ratio of the bottom surface protrusion height h of the heat absorber case 2 to the height H of the heat absorber case 2 of the present embodiment is 1. FIG. In this way, when the wall absorptivity is 0.7 and h / H=1, the optical efficiency of the bottom surface convex cylindrical cavity type solar heat absorber is 78.331%, which is better than the ideal of the metal tube at the bottom surface of the heat absorber coiling the entire bottom surface. In this case, the optical efficiency of the cylindrical cavity absorber is 2.848% higher. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com