Detachable electrode

A technology of electrodes and electrode caps, which is applied in the field of working electrode structures, can solve the problems of cumbersome production steps, long time-consuming, and heavy workload, and achieve the effect of simple installation steps, short time-consuming, and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

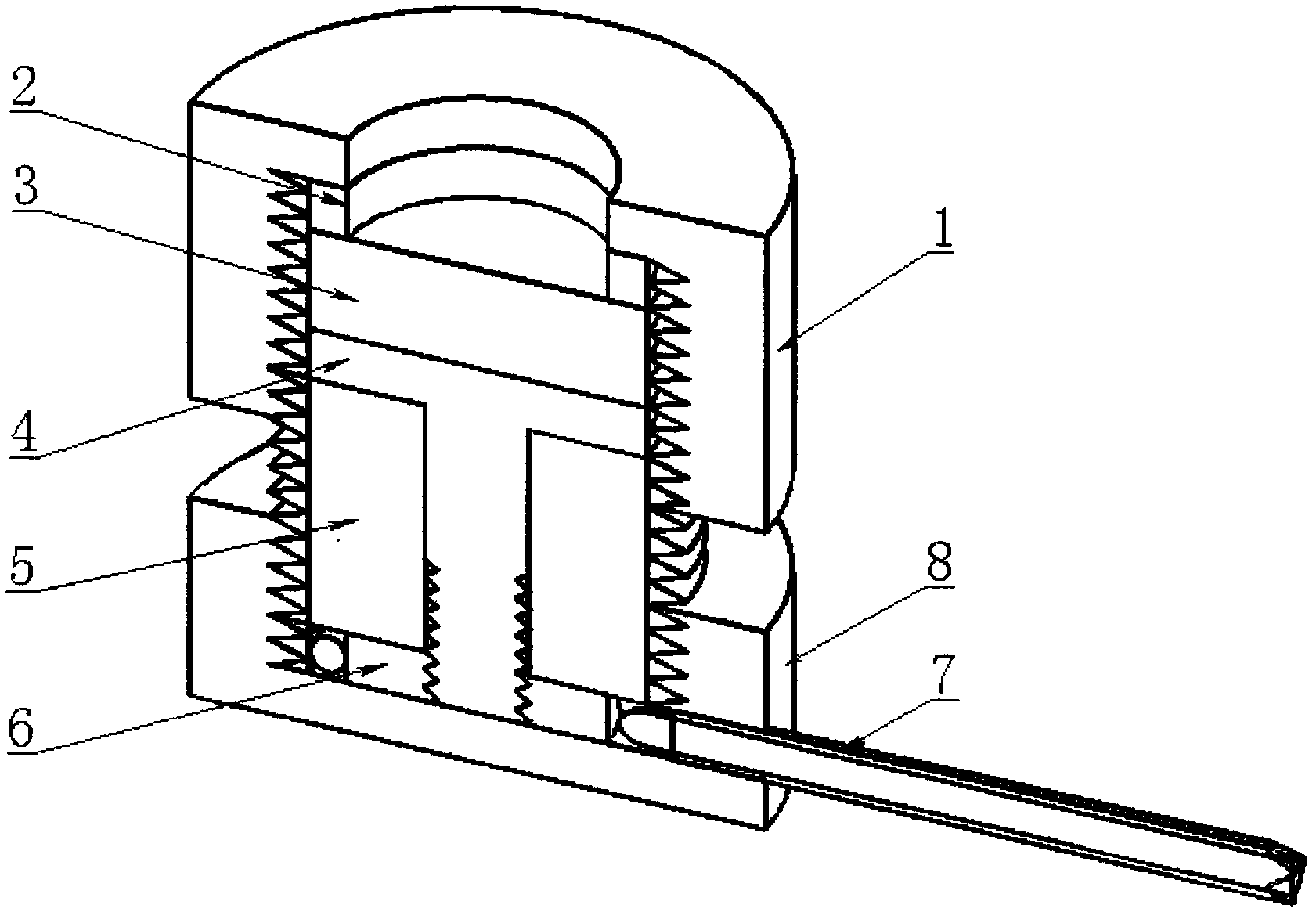

[0030] The following structural drawings further describe the present invention.

[0031] like figure 1 As shown, the present invention includes an electrode cap 1, an electrode sealing rubber sheet 2, an electrode test piece 3, an electrode conductive connection bolt 4, an electrode fixing bolt 5, an electrode conductive connection nut 6, a wire 7 and an electrode back seat 8, wherein the electrode conductive connection One end of the bolt 4 is inserted in the electrode fixing bolt 5, and is threaded through the lower surface of the electrode fixing bolt 5 and connected with the electrode conductive connecting nut 6, and the outer surfaces of the two ends of the electrode fixing bolt 5 are respectively threaded. The electrode cap 1, the electrode back seat 8, the electrode conductive connection nut 6 is accommodated in the electrode back seat 8, one end of the wire 7 is connected to the electrode conductive connection nut 6, and the other end is passed through the electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com