Highly miniaturized substrate integrated waveguide resonator

A substrate integrated waveguide and resonator technology, applied in the direction of resonators, waveguide devices, electrical components, etc., can solve the problems of large volume, unfavorable system miniaturization design, and difficulty in reducing circuit size, etc., to reduce the circuit area , good out-of-band suppression ability, reduce the effect of mutual coupling and crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

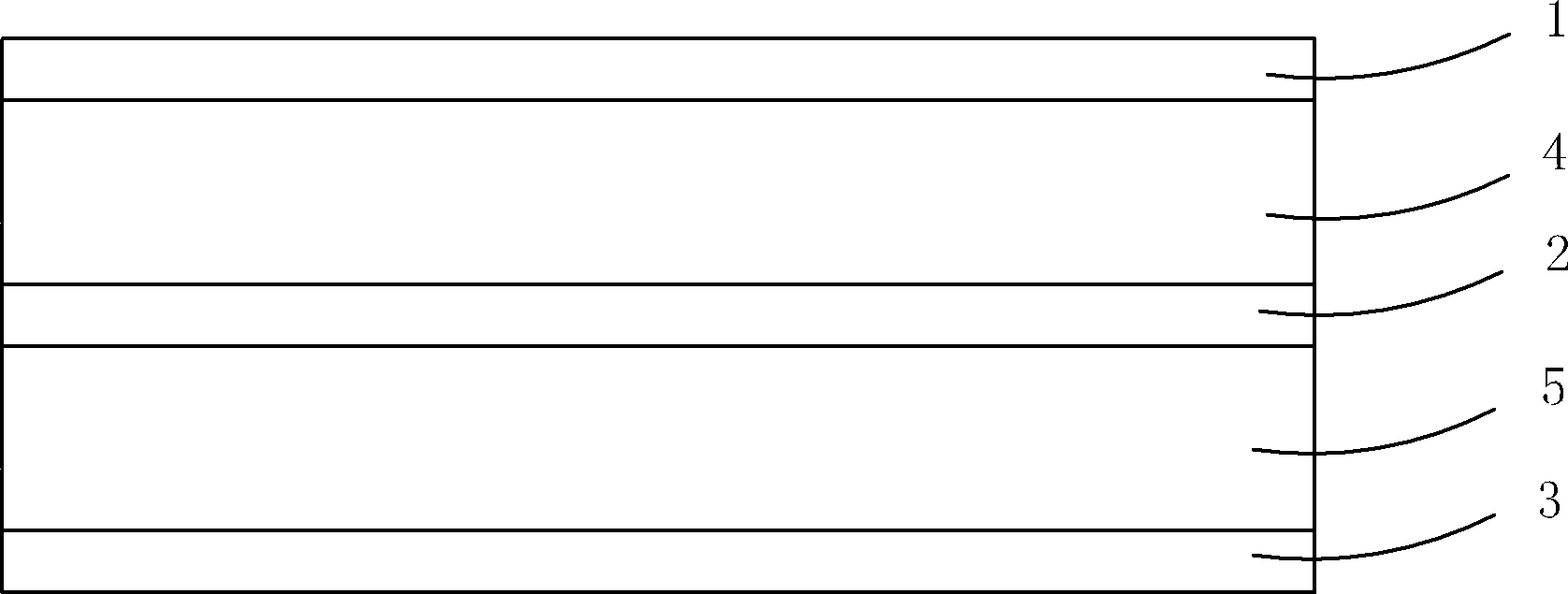

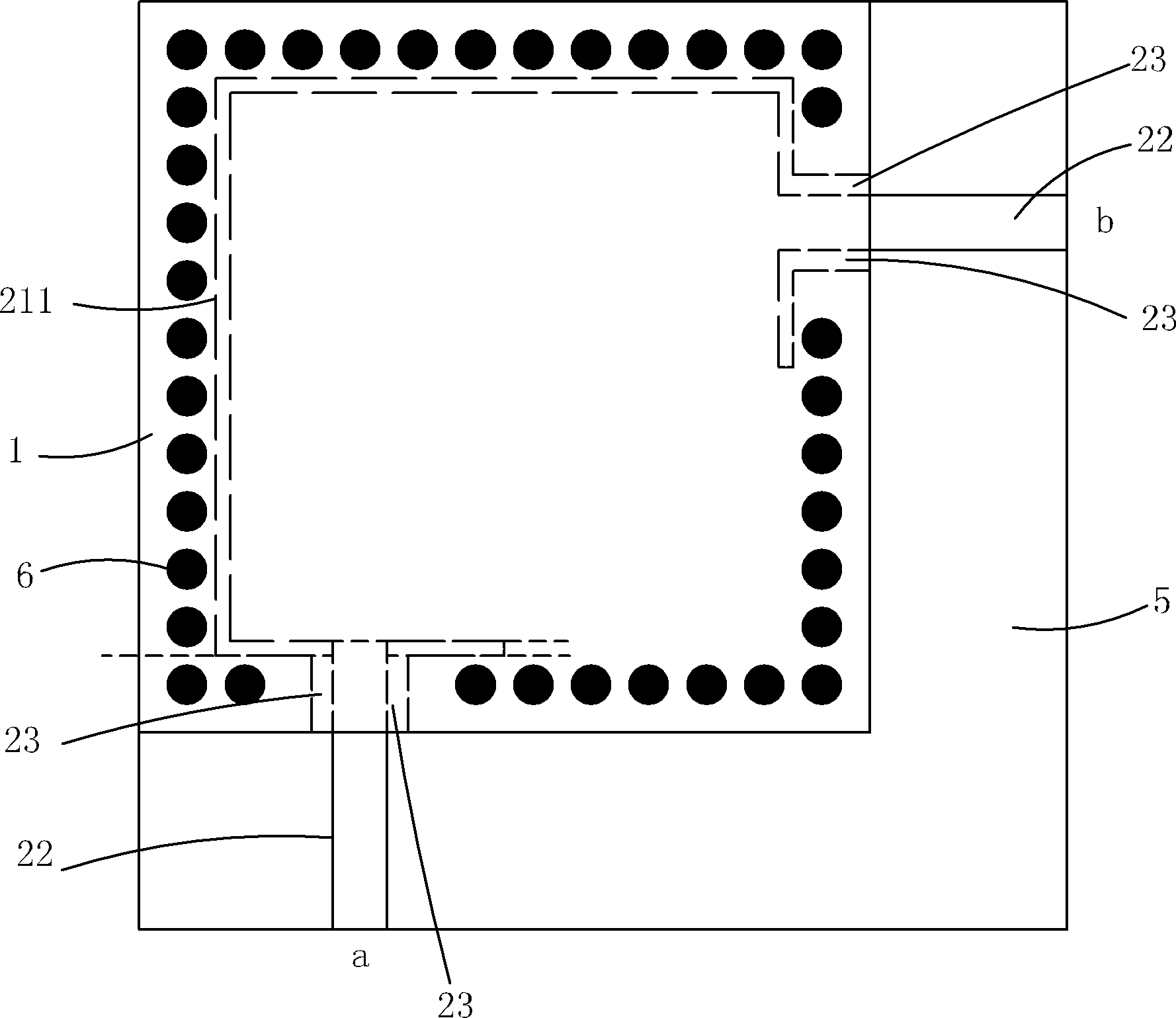

[0021] Embodiment 1: as figure 1 , figure 2 As shown, a highly miniaturized substrate-integrated waveguide resonator includes a first metal copper-clad layer 1, a first dielectric layer 4, a second metal copper-clad layer 2, and a second dielectric layer stacked sequentially from top to bottom. 5 and the third metal copper clad layer 3, in order to form the highly miniaturized substrate integrated waveguide resonator of the present invention, the second metal copper clad layer 2 is processed to form the required metal pattern ( Circuit structure), the first metal copper clad layer 1 and the third metal copper clad layer 3 are not processed, and the parts in the pattern are divided by imaginary short dashed lines, and the metallized through holes 6 pass through the first metal clad layer in turn. The copper layer 1, the first dielectric layer 4, the second metal copper clad layer 2, the second dielectric layer 5 and the third metal copper clad layer 3 are connected to form tw...

Embodiment 2

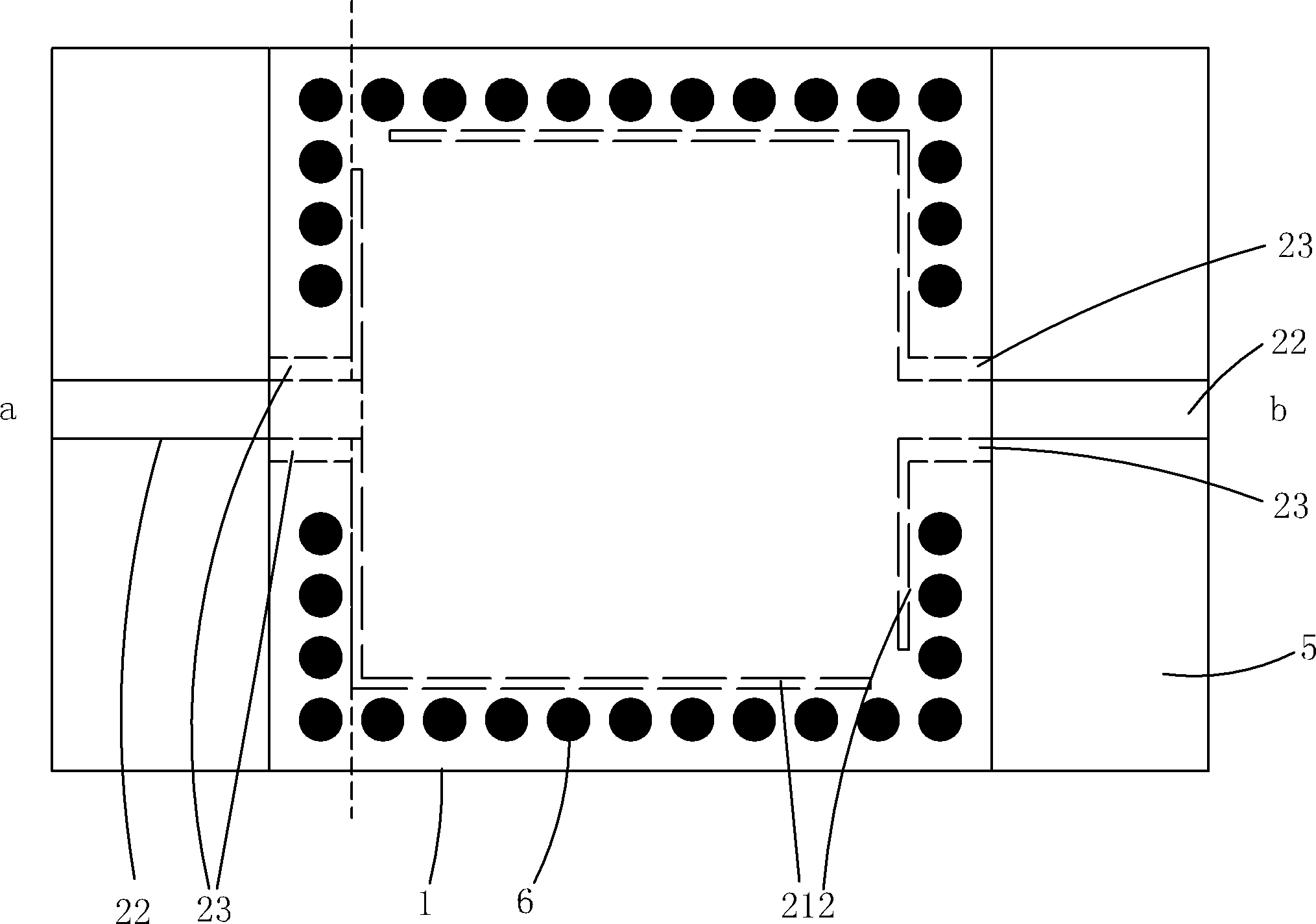

[0024] Embodiment 2: as figure 1 , image 3 As shown, a highly miniaturized substrate-integrated waveguide resonator includes a first metal copper-clad layer 1, a first dielectric layer 4, a second metal copper-clad layer 2, and a second dielectric layer stacked sequentially from top to bottom. 5 and the third metal copper clad layer 3, in order to form the highly miniaturized substrate integrated waveguide resonator of the present invention, the second metal copper clad layer 2 is processed to form the required metal pattern ( circuit structure), the first metal copper-clad layer 1 and the third metal copper-clad layer 3 are not treated, the parts in the pattern are divided by imaginary short dashed lines, and the metallized through holes 6 pass through the first The metal copper clad layer 1, the first dielectric layer 4, the second metal copper clad layer 2, the second dielectric layer 5 and the third metal copper clad layer 3 are connected to form two stacked square cavit...

Embodiment 3

[0027] Embodiment 3: as figure 1 , Figure 4 As shown, a highly miniaturized substrate-integrated waveguide resonator includes a first metal copper-clad layer 1, a first dielectric layer 4, a second metal copper-clad layer 2, and a second dielectric layer stacked sequentially from top to bottom. 5 and the third metal copper clad layer 3, in order to form the highly miniaturized substrate integrated waveguide resonator of the present invention, the second metal copper clad layer 2 is processed to form the required metal pattern ( circuit structure), the first metal copper-clad layer 1 and the third metal copper-clad layer 3 are not treated, the parts in the pattern are divided by imaginary short dashed lines, and the metallized through holes 6 pass through the first The metal copper-clad layer 1, the first dielectric layer 4, the second metal copper-clad layer 2, the second dielectric layer 5 and the third metal copper-clad layer 3 are connected to form two sets of stacked iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com