Gear hot-stamping equipment and gear hot-stamping method

A stamping equipment, hot stamping technology, applied in the direction of gears, metal processing equipment, other household appliances, etc., can solve the problems of wasting production resources, low production efficiency, complicated process, etc., to improve production efficiency, improve service life and precision, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

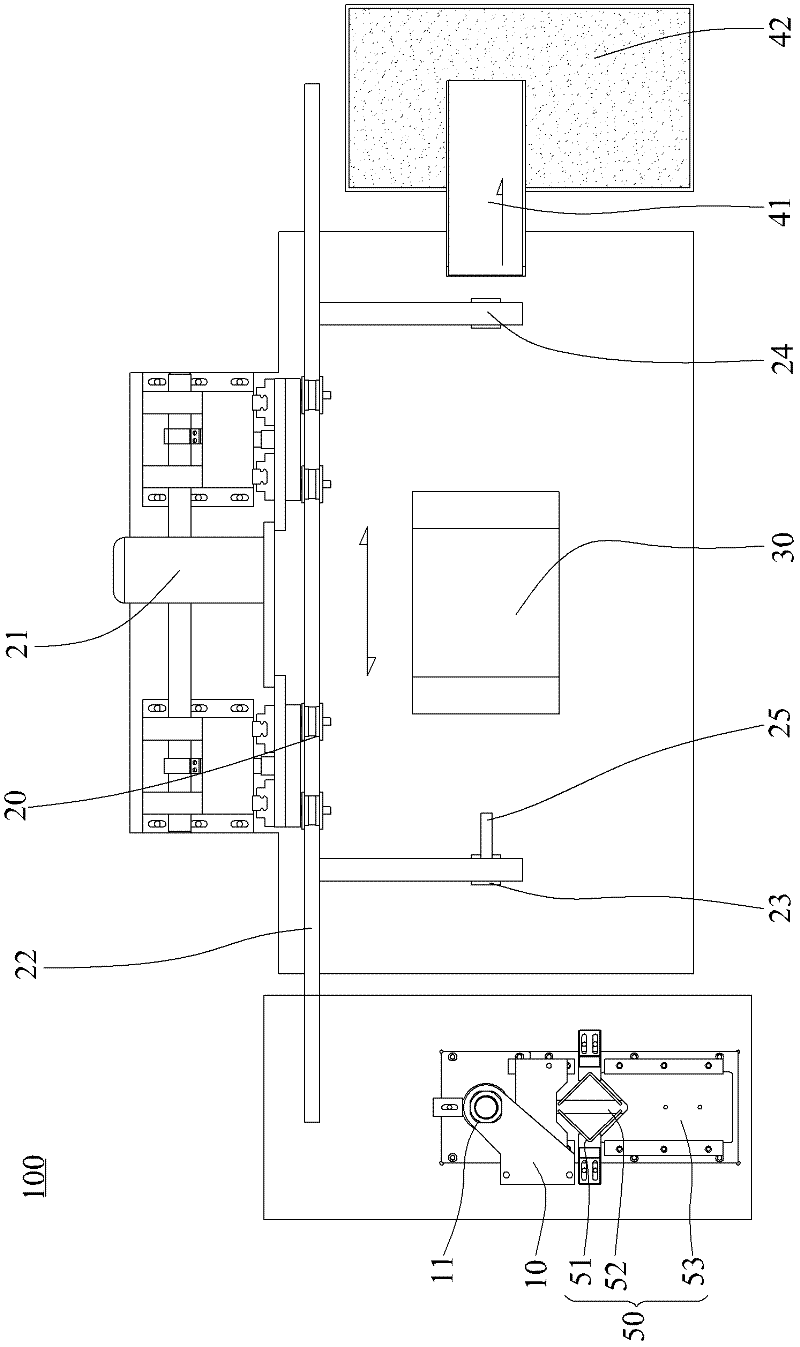

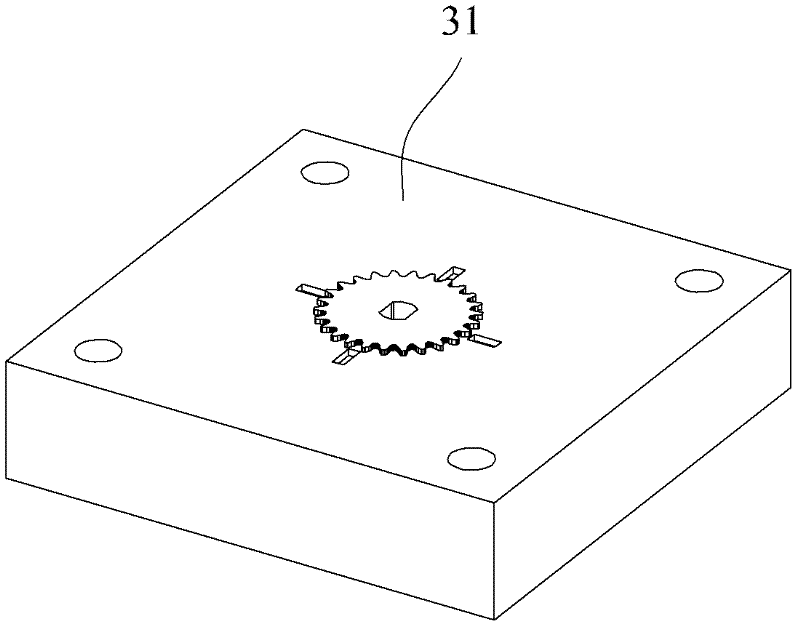

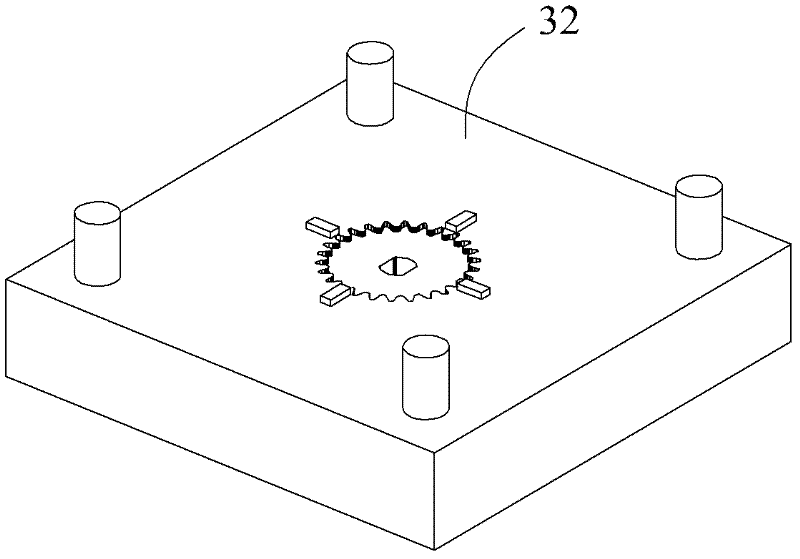

[0040] refer to Figure 1-Figure 9 , the gear hot stamping equipment 100 of the present invention includes a method for processing gears by hot stamping, which includes a heating system, a stamping die 30, a turnover tank 41, a quenching box 42, a conveying system 20 and an intelligent control system 70, and the heating system uses The stamping die 30 stamps the heated blank material into gears; the turnover box 41 is used to introduce the hot stamped gears into the quenching box 42; the quenching box 42 is used for stamping Good gear quenching; the conveying system 20 is used to convey the heated blank material to the stamping die 30 and convey the stamped gear to the turnover box 41; the intelligent control system 70 coordinates and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com