Machining machine tool for valve body valve rod hole

A technology for processing machine tools and valve stem holes, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of not having processing tools, high production costs, and prone to error operations, etc., and achieves a high degree of automation, Reduced manufacturing costs and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

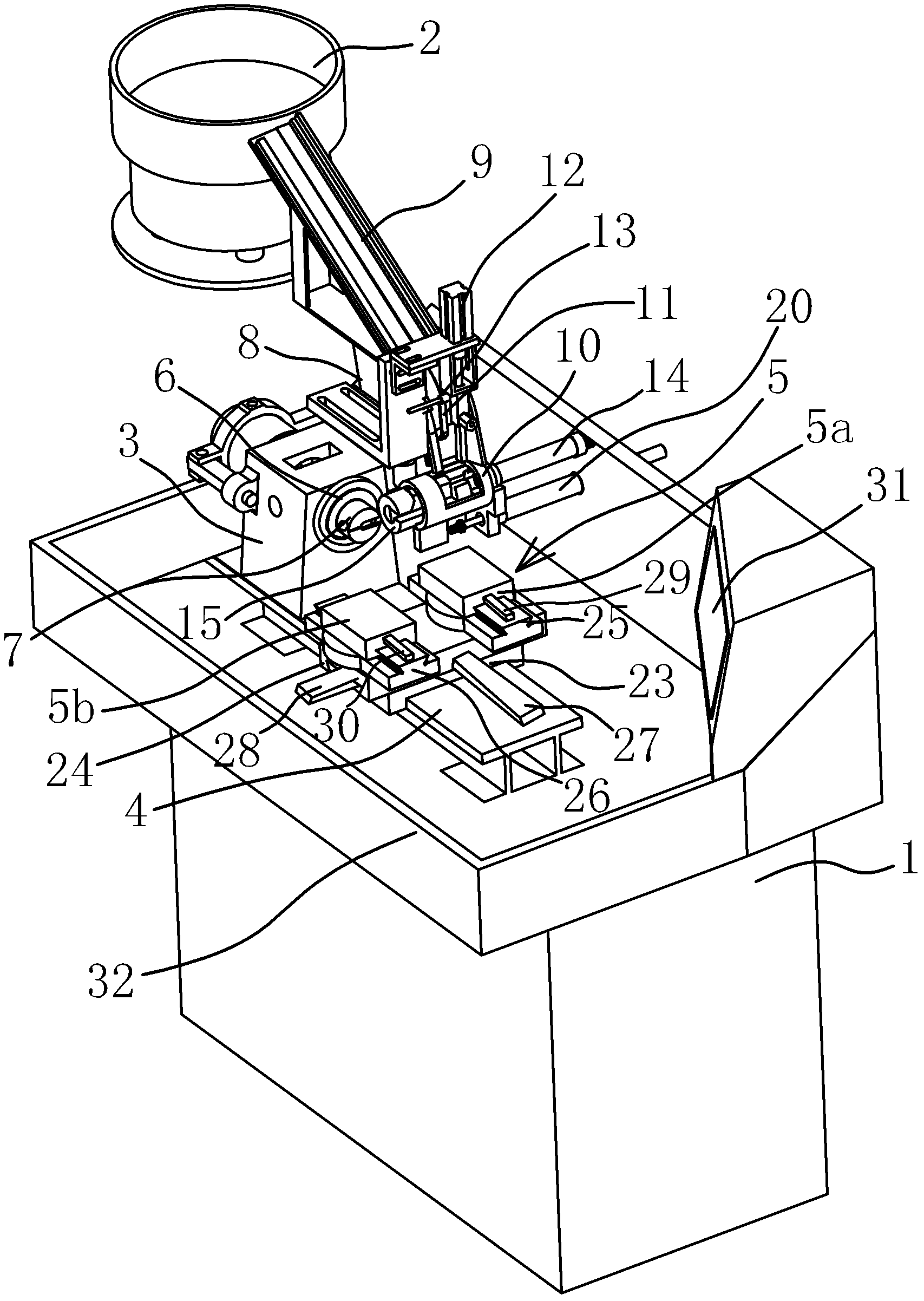

[0030] The machine tool for valve stem hole processing of valve body is composed of bed 1, feeding hopper 2, spindle box 3, horizontal guide rail 4 and processing tool holder 5, etc. Can be ball valve body or gate valve body.

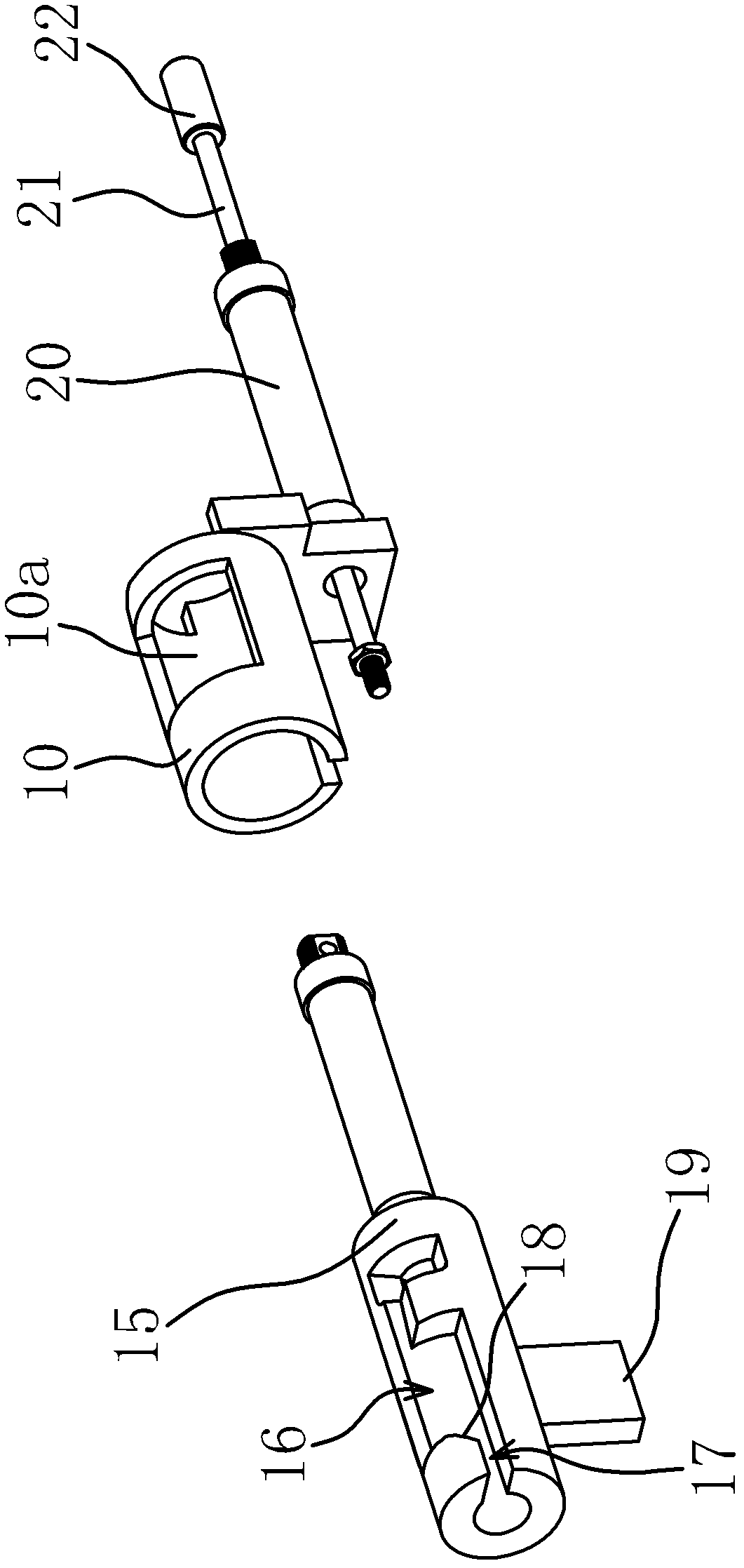

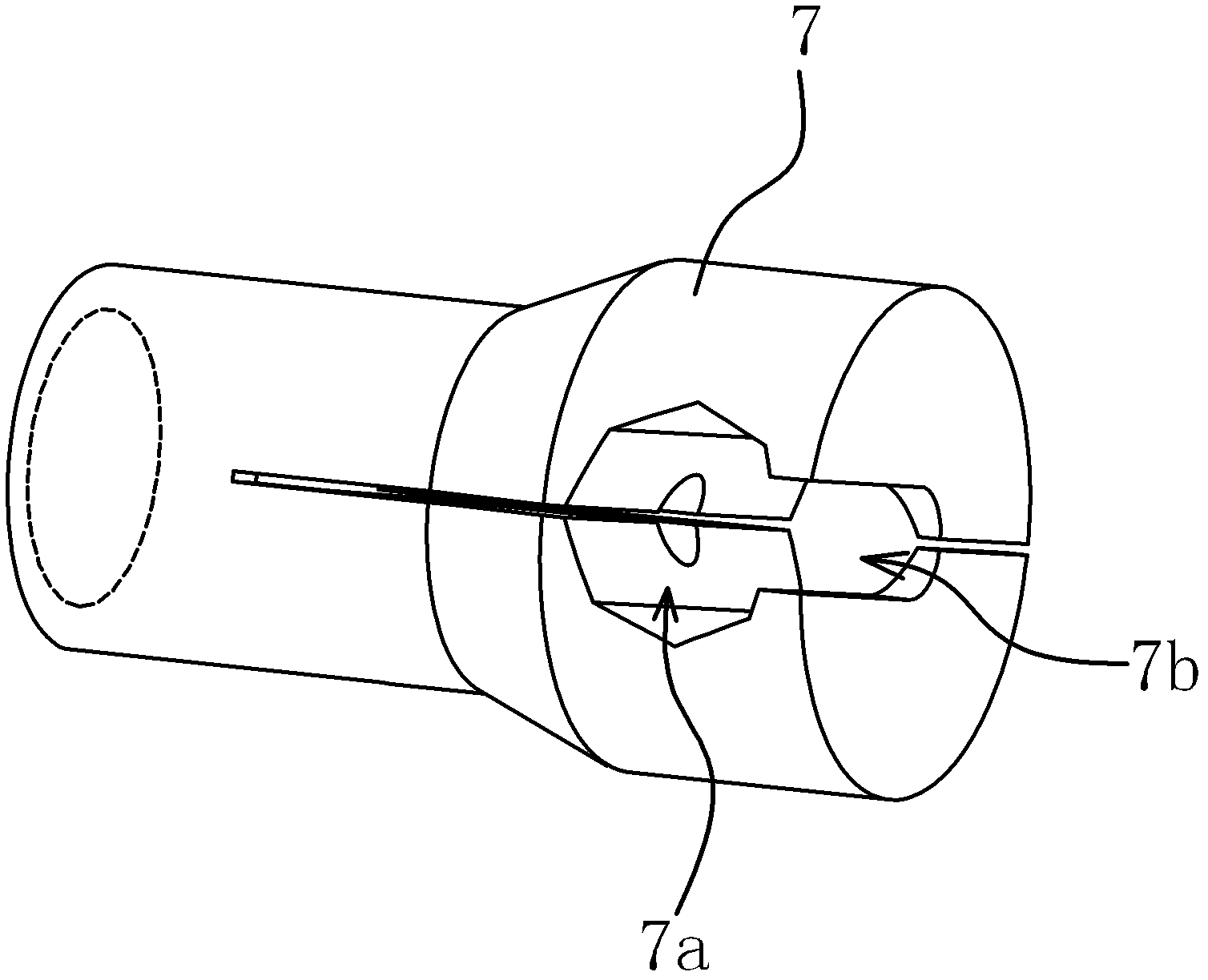

[0031] Specifically, as figure 1 As shown, the bed 1 is provided with a transverse guide rail 4, and the transverse guide rail 4 is provided with a processing tool holder 5 for processing valve stem holes. The processing tool holder 5 includes a drilling tool holder 5a and a turning tool holder 5b. Horizontal carriage 4 is provided with horizontal carriage 23, and transverse carriage 23 is provided with vertical carriage 24, and vertical carriage 24 is fixed with horizontally arranged and parallel ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap