Quality monitor soft sensing method based on rubber mixing process

A quality monitoring and rubber mixing technology, applied in the field of rubber tire manufacturing, can solve the problems of Mooney viscosity value hysteresis, uncertainty, time-consuming and laborious, etc., to reduce the possibility of false alarms, reduce errors or errors, Predict accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

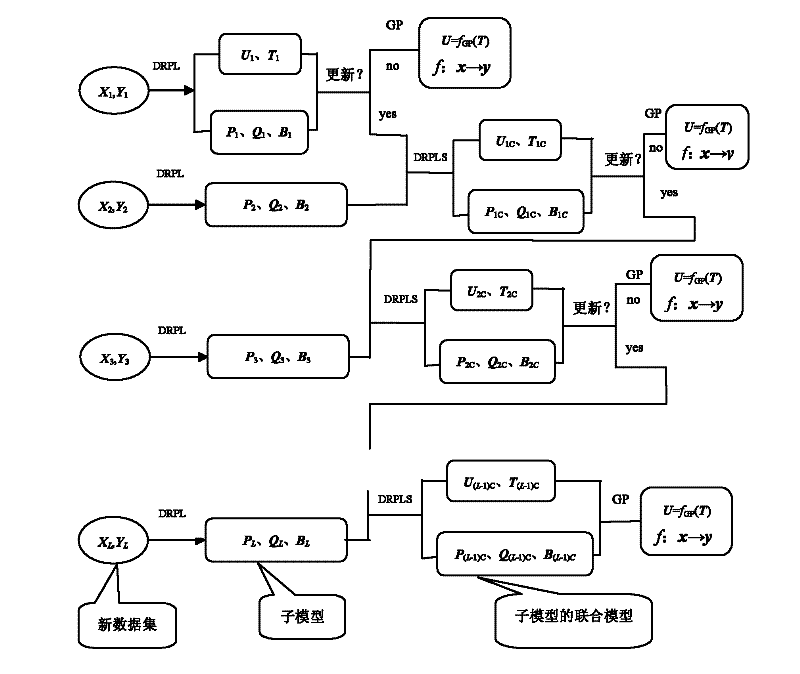

Method used

Image

Examples

Embodiment Construction

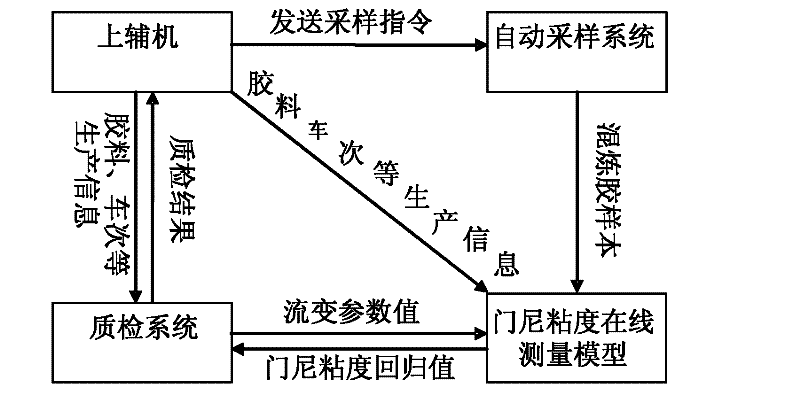

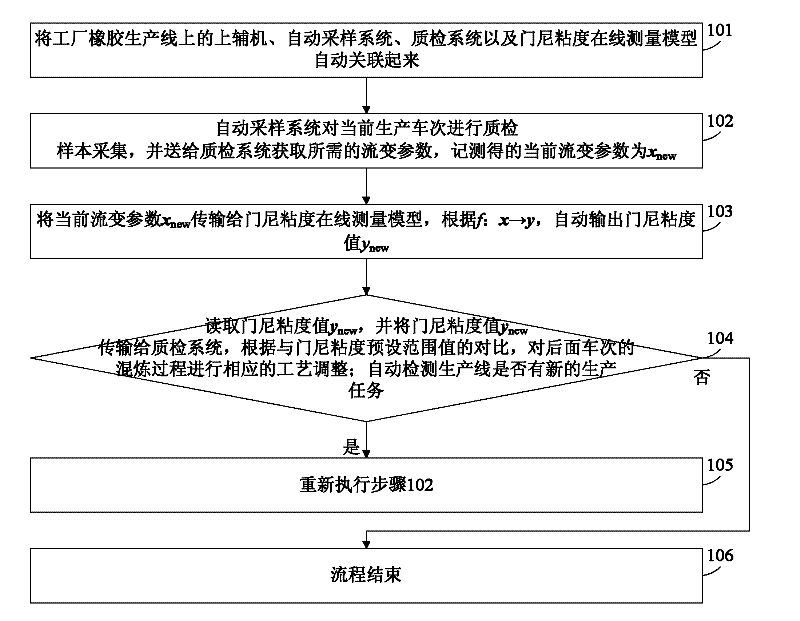

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] Rheological parameters are also an important quality indicator for rubber production. Its measurement cycle is relatively short, and it takes about five minutes from sampling to measurement. The quality information of rubber can be obtained in time, and it must be carried out in the rubber quality inspection process. link. Through the research on the measurement principle of rheology and Mooney viscosity, it is found that their quality inspection has a close internal relationship, so through the appropriate soft measurement method, the rheological data can be obtained in time by using the rheological parameter regression to predict the Mooney viscosity. The Mooney viscosity with relatively large hysteresis can greatly shorten it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com