Preparation method for even-orientation-degree organic glass

A technology of plexiglass and degree of orientation, applied in the field of preparation of oriented plexiglass, can solve the problems of affecting the appearance and optical quality of sheet-formed products, deterioration of optical properties, uneven mechanical properties of oriented plexiglass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

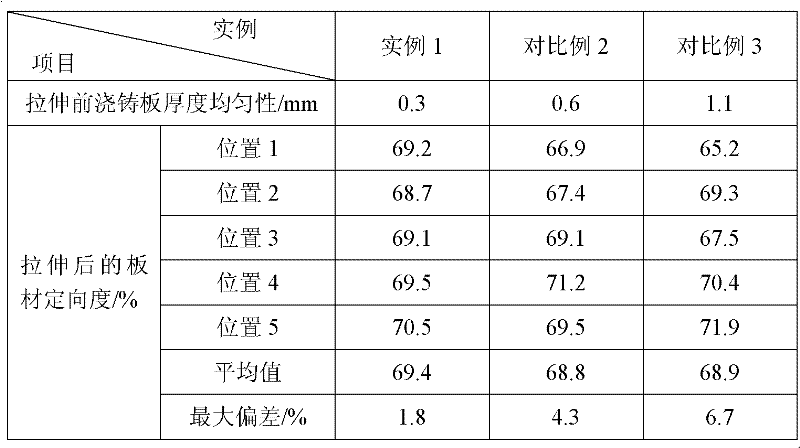

Embodiment 1

[0017] Step 1: Put a 1600×1600×20mm plexiglass casting plate on the grinder with 120 # Grind with sandpaper for 30 minutes, then turn the plate over, grind the other side for 30 minutes, take it off, and measure the thickness of the plate with an ultrasonic thickness gauge, and measure no less than 81 points as evenly as possible.

[0018] Step 2: Fix the plate on the fixture of the stretching machine, and perform directional stretching at 125°C to 160°C. During the stretching process, ensure that the temperature uniformity in the insulation chamber is not greater than 3°C, and the entire plexiglass plate is stretched out. Long reach 70% stop.

[0019] Step 3: After the stretching is completed, cool down the sheet to room temperature and remove the sheet. Cut off 300mm of its edge. Attached figure 1 Take samples as shown and measure their degree of orientation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness uniformity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com