Preparation process for pyramid lattice sandwich structure

A technology of a sandwich structure and a preparation process is applied in the field of preparation technology of a pyramid lattice sandwich structure, which can solve the problems of low production efficiency and complex process, and achieve the effects of high production efficiency, simple operation process and exertion of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific implementation mode one: combine Figure 1-Figure 9 Describe this embodiment, the preparation process of a kind of pyramid lattice sandwich structure of this embodiment is as follows:

[0034] Step 1: Prepare the corrugated plate 1 with notches. The method for preparing the corrugated plate 1 with notches is a one-time molding hot pressing method. The specific process of the one-time molding hot pressing method is as follows:

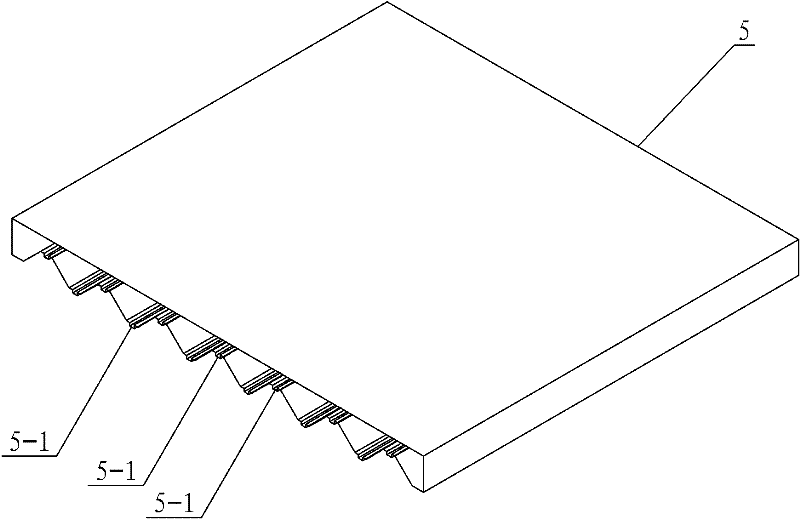

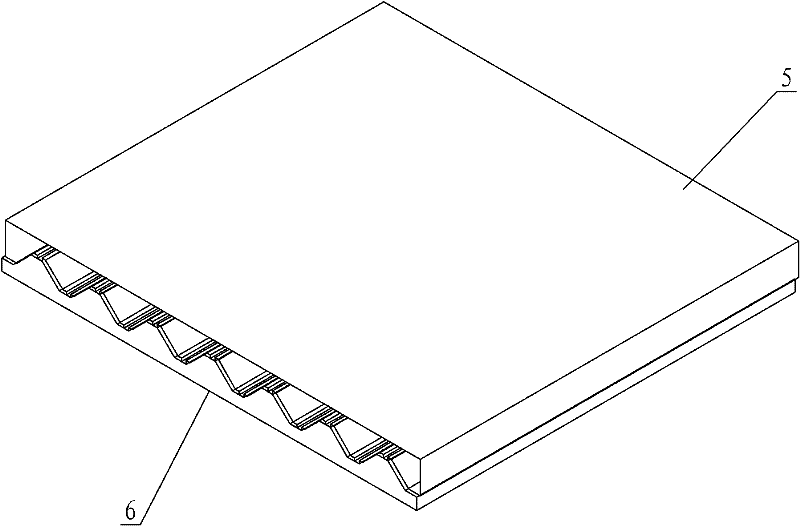

[0035] Design and manufacture a mold that matches the upper mold 5 and the lower mold 6, the upper mold 5 is provided with a boss 5-1, the surface of the mold is cleaned with an acetone solution, and then the outer surface of the mold is treated with a release agent;

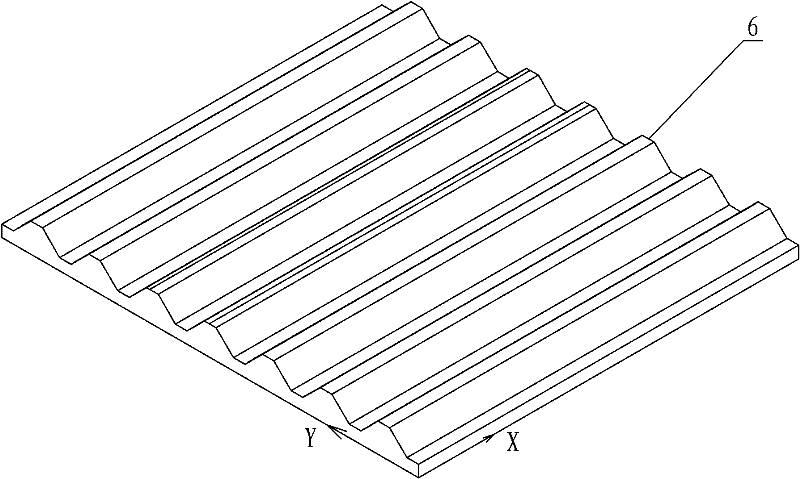

[0036] Lay the pre-impregnated non-weft cloth on the upper surface of the lower mold 6, and ensure that the fiber direction in the non-weft cloth is laid along the y-axis direction, that is, perpendicular to the direction of the channel x in the mould;

[0037] Close the ...

specific Embodiment approach 2

[0043] Specific implementation mode two: combination Figure 1-Figure 9 To illustrate this embodiment, in Step 1 of this embodiment, the non-weft fabric is carbon fiber, glass fiber, aramid fiber or woven fiber cloth prepreg. It is convenient to prepare the fiber-reinforced pyramid lattice core 3 . Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0044] Specific implementation mode three: combination Figure 10 To describe this embodiment, in Step 1 of this embodiment, the corners of the upper mold and the lower mold are provided with arc chamfers. The stress concentration generated by the mold during the preparation of the lattice structure is effectively reduced. Other method steps are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com