Environment friendly H-shaped combination beam and processing method thereof

An I-shaped and composite beam technology is applied in the field of column structures and beams, which can solve the problems of low utilization rate of bamboo boards or wood boards, a large amount of steel used, and insufficient mechanical properties of bamboo/wood boards to be fully exerted, so as to save energy. The effect of steel consumption, pollution reduction, high bearing capacity and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

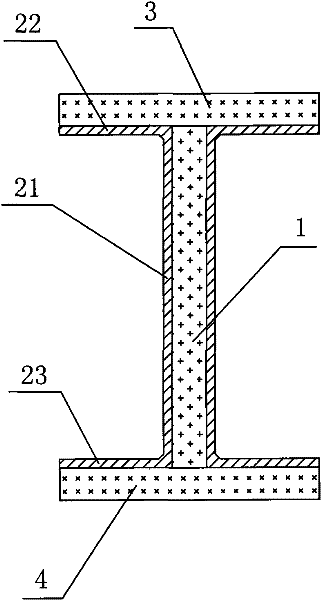

[0023] Embodiment 1: As shown in the figure, an environmentally friendly I-shaped composite beam includes a bamboo main web 1 and two "["-shaped channel steel plates opposite to each other. The web part of the channel steel plate 21 is fixedly bonded to the side of the main web 1 by an adhesive, and the upper end of the main web 1 is fixedly bonded with the upper main flange 3 of bamboo through an adhesive, and the upper end surface of the upper flange 22 of the channel steel plate is connected to the upper main flange 3 The lower end surface of the main web 1 is fixed and bonded by an adhesive, the sum of the width of the main web 1 and the width of the upper flange 22 of the two channel steel plates is equal to the width of the upper main flange 3, and the lower end of the main web 1 is fixed and bonded by an adhesive. The lower main flange 4 of bamboo, the lower end surface of the lower flange 23 of the channel steel plate and the upper end surface of the lower main flange 4...

Embodiment 2

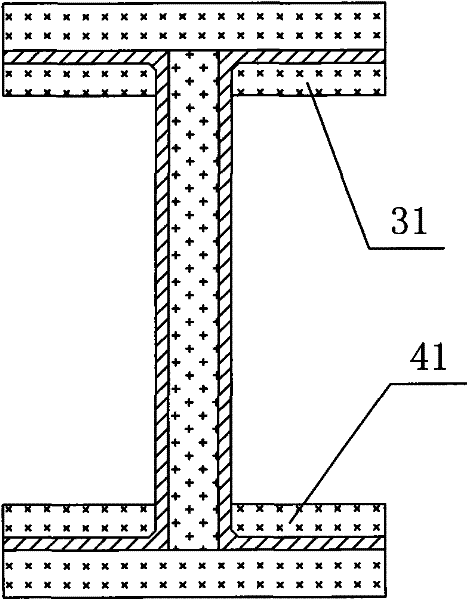

[0030] Embodiment two: as shown in the figure, other structures are the same as embodiment one, and the difference is that the lower end surface of the upper flange 22 of the channel steel plate is fixedly bonded with an auxiliary upper flange 31 of bamboo by adhesive, and the auxiliary upper flange The width of edge 31 is equal to the width of the upper flange 22 of channel-shaped steel plate, and the auxiliary lower flange 41 of bamboo is fixedly bonded with bamboo on the upper end surface of the lower flange 23 of channel-shaped steel plate, and the width of auxiliary lower flange 41 It is equal to the width of the lower flange 23 of the channel steel plate.

[0031] The specific processing process of the above-mentioned composite beam is as follows:

[0032] (1) Process two "["-shaped thin-walled channel steel plates by hot rolling, cold bending or steel plate welding;

[0033] (2) Use a grinder to remove the rust and galvanized layer on the outer surface of the channel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com