Method for preparing recycled concrete by using sucrose water reducer and recycled concrete

A technology of recycled concrete and water reducer, applied in the field of recycled concrete, can solve the problems of poor mechanical properties of recycled concrete, achieve performance improvement, wide application, and reduce pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

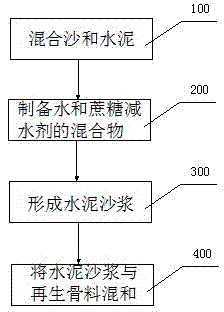

[0024] like figure 1 As shown, the specific embodiment of the present invention is: provide a kind of method utilizing sucrose water reducing agent to prepare recycled concrete, comprise the steps:

[0025] Step 100: mixing sand and cement, that is, stirring and mixing an appropriate amount of cement and sand according to the requirements of the mix ratio of different concrete grades. During the specific implementation process, an appropriate amount of cement and sand is stirred and mixed for 20 seconds to 40 seconds, and usually, an appropriate amount of cement and sand is stirred and mixed for 30 seconds.

[0026] Step 200: Prepare a mixture of water and sucrose water reducer, namely: add an appropriate amount of sucrose water reducer into water and stir to mix.

[0027] Step 300: Forming cement mortar, that is: adding a mixture of cement and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com