Intelligent mud jacking measurement and control system of large-circulation prestress pipeline

A technology of prestressed pipelines and measurement and control systems, which is applied in the direction of basic structure engineering, architecture, building construction, etc., can solve the problems that the air cannot be effectively eliminated, cannot be adjusted adaptively, and cannot completely exhaust the air in the tunnel, so as to achieve convenience The effect of quality management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

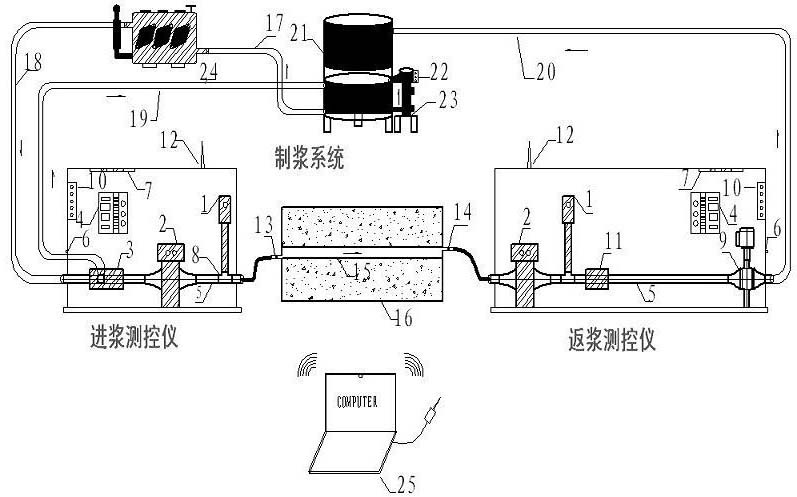

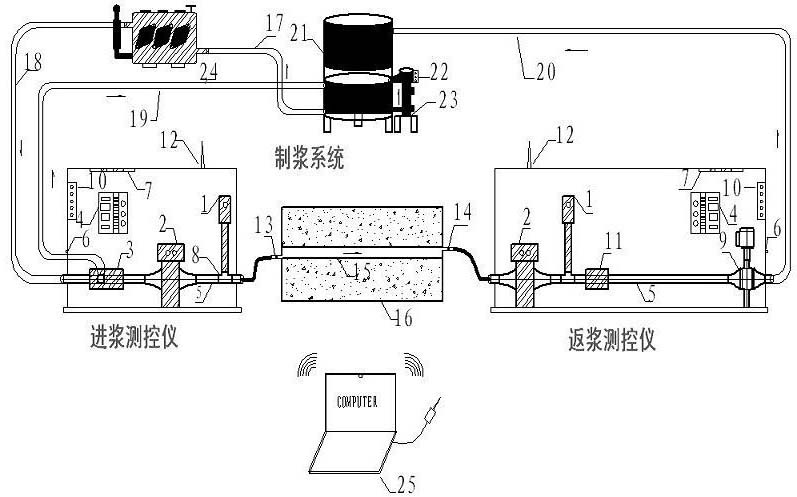

[0016] basic introduction figure 1 Important components in:

[0017] 1. Pressure sensor 1: A solid piezoresistive pressure sensor is used to measure the pressure by the current change signal generated by the resistivity change of the solid under pressure.

[0018] 2. Electromagnetic flowmeter 2: It consists of two parts: a sensor and a converter, and measures the flow through the current change generated by the change of the magnetic field strength.

[0019] 3. Electromagnetic reversing valve 3: The electric signal input by the control circuit generates a corresponding magnetic signal in the electromagnetic valve to drive the electromagnet to produce a reversing action to realize the reversing.

[0020] 4. Electric pressure regulating valve 9: The stepper motor is controlled by the pulse signal to drive the valve core to move to realize the working function.

[0021] 5. Electromagnetic cut-off valve 11: The electric signal input by the control circuit generates a correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com