Anti-backflow motorcycle exhaust

A technology for exhaust devices and motorcycles, applied in exhaust devices, mufflers, engine components, etc., can solve the problems of high temperature of the secondary air valve hose, insufficient exhaust gas catalysis, and unqualified exhaust gas, etc., to improve the conversion rate. Efficiency, burnout prevention, effect of reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

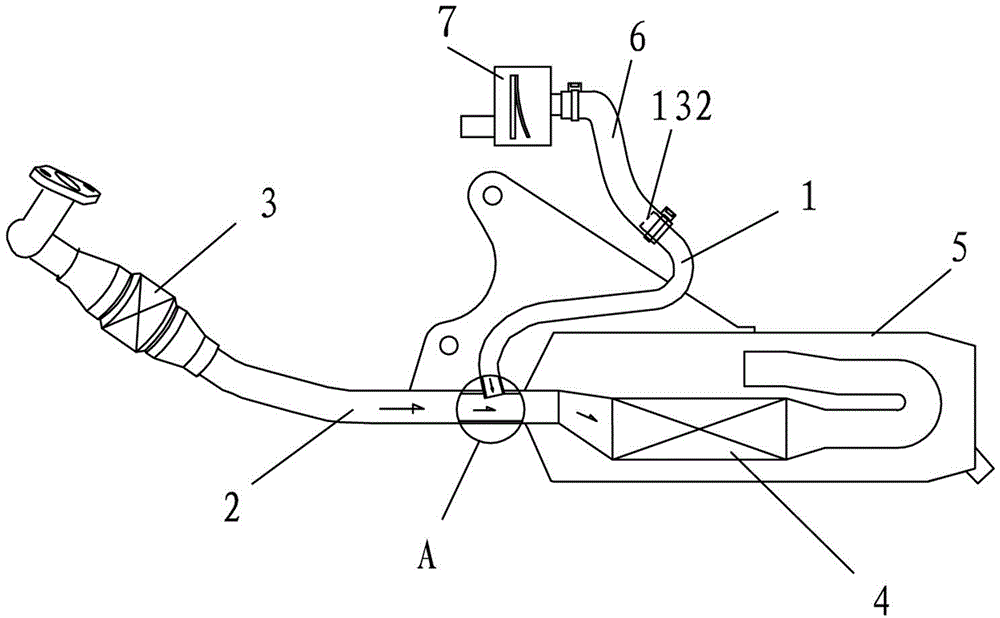

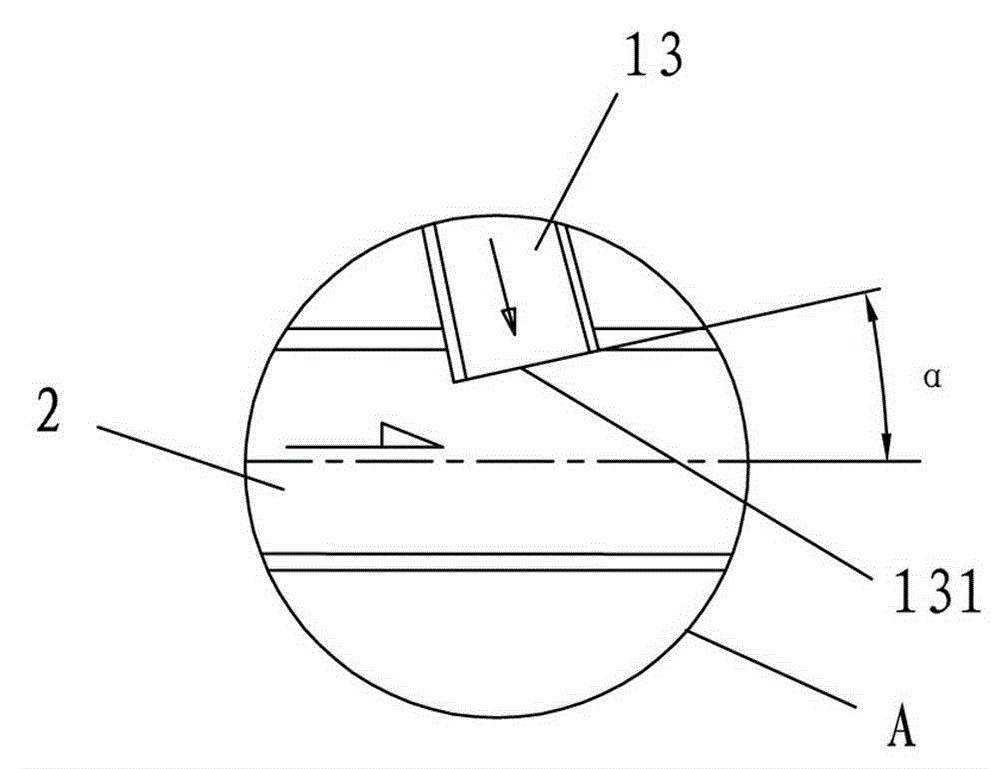

[0018] refer to Figure 2 to Figure 4 , the embodiment of the anti-backflow motorcycle exhaust device of the present invention includes an exhaust pipe 2 and an air supply pipe 1, the air supply pipe 1 has two bending sections 11, 12, and a first The bending section 11 is provided with a second bending section 12 near the air inlet 132 of the air supply pipe 1, the bending angle of the first bending section 11 and the second bending section 12 is less than 90 degrees, and the two bending angles The opposite direction makes the air supply pipe 1 in an "S" shape, which can effectively prevent the exhaust gas in the exhaust pipe 2 from entering the air supply pipe 1, inhibit the backflow of exhaust gas through the air supply pipe 1, and ensure the smooth progress of the secondary air supply.

[0019] Further, the angles of the two bending sections 11 and 12 are both less than 90 degrees, the bending angle β of the first bending section 11 is preferably 68-75 degrees, and the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com