Method for assembling LED lighting lamp

A technology for LED lighting lamps and LED bulbs, which is applied to the components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc. Low, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

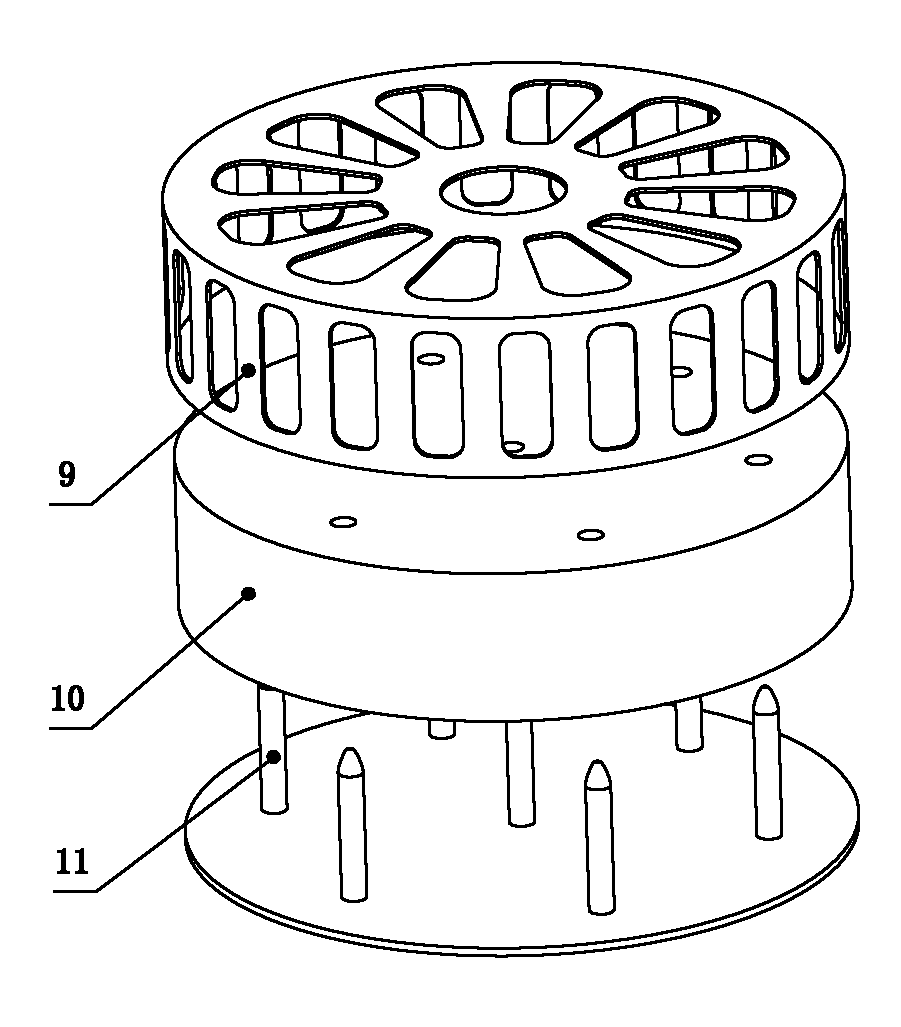

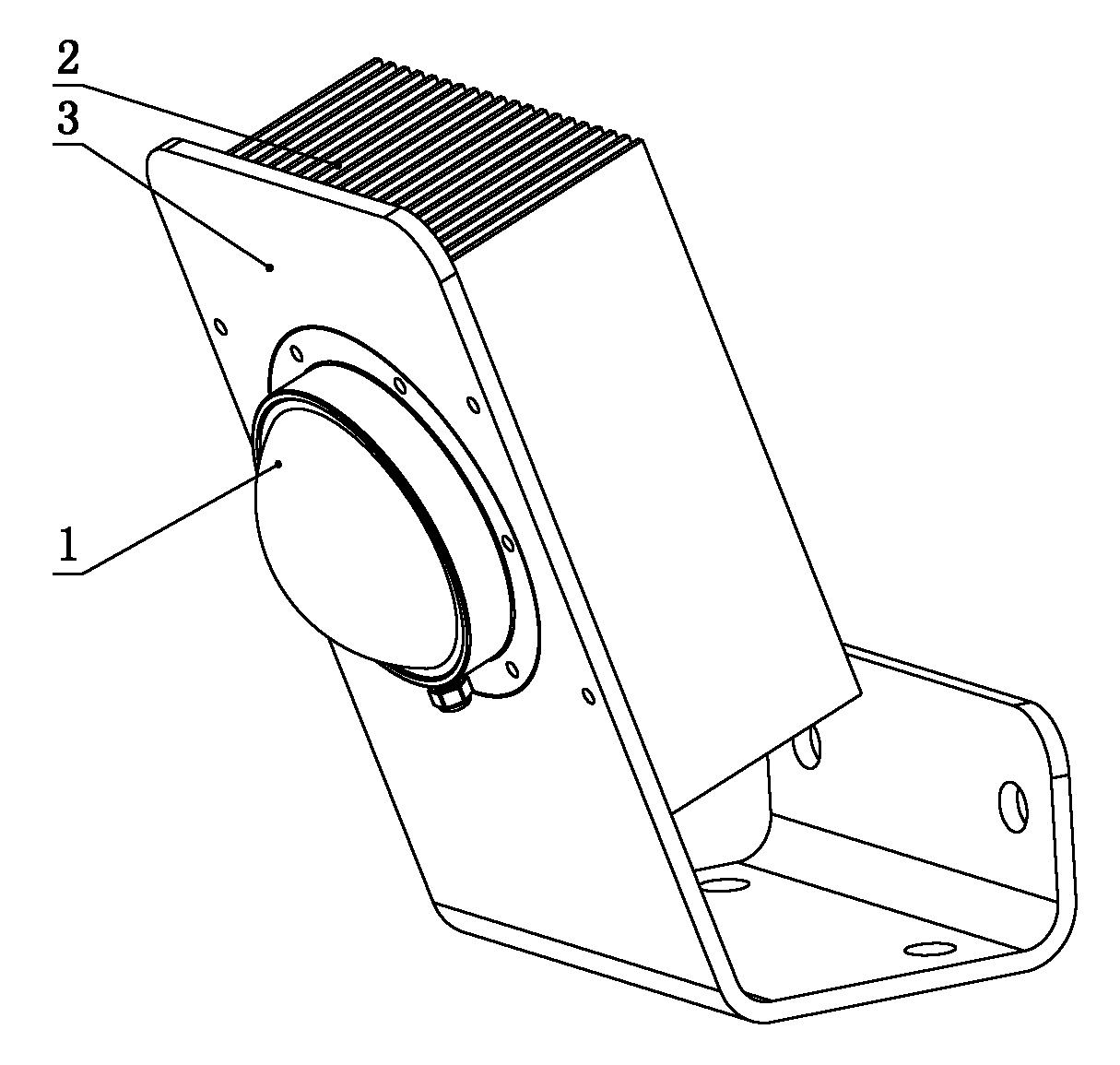

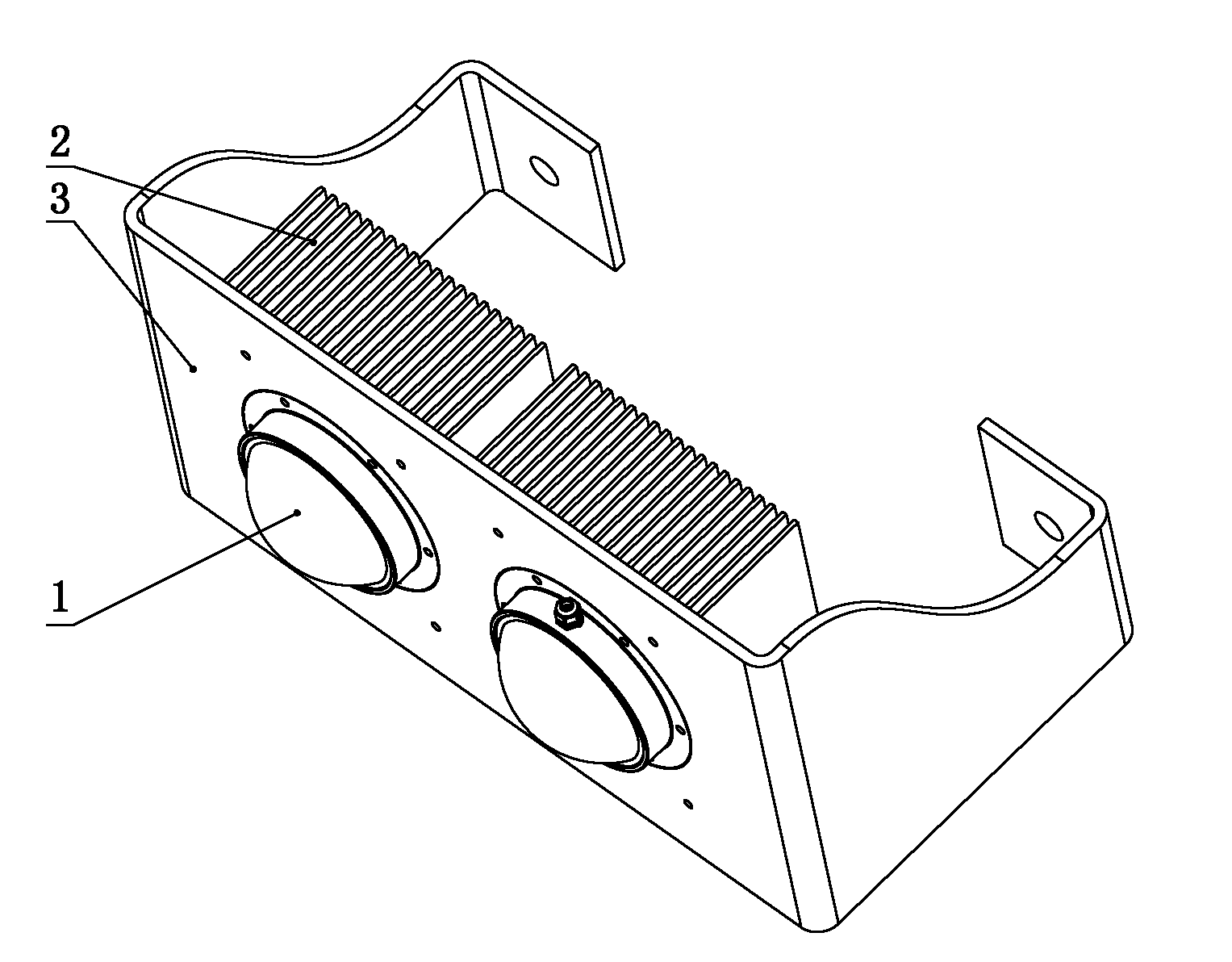

[0025] A method for assembling LED lamps, in which one or more heat sinks 2 are arranged on a fixed orifice plate 3 formed by metal stamping, and one or more standard interface LED bulbs 1 are installed on the heat sink 2, and the standard interface LED light bulbs 1 is a standard interface LED light bulb integrated with an LED light module. The radiator 2 is extruded metal profile, non-metallic sintered heat-conducting material molding, die-casting metal parts or a radiator made of heat pipe 11, foam metal 10 and metal protective cover 9, heat pipe 11 is arranged in foam metal 10, The metal protective cover 9 is located outside the foam metal 10 . Such as figure 1 shown. The standard interface LED light bulb 1 is integrated with an independent driving power supply. The fixed orifice plate 3 is formed by stamping, cutting or die-casting, whether it can be installed with a metal or non-metal plate to fix the radiator 2. The fixed orifice plate 3 is stamped, cut or die-caste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com