Foil winding coil mold for multiple copper bar outgoing lines

A mold and coil technology, used in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of low production efficiency, uneven arrangement of copper bars, and unsightly appearance, and achieve high production efficiency, neat arrangement, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

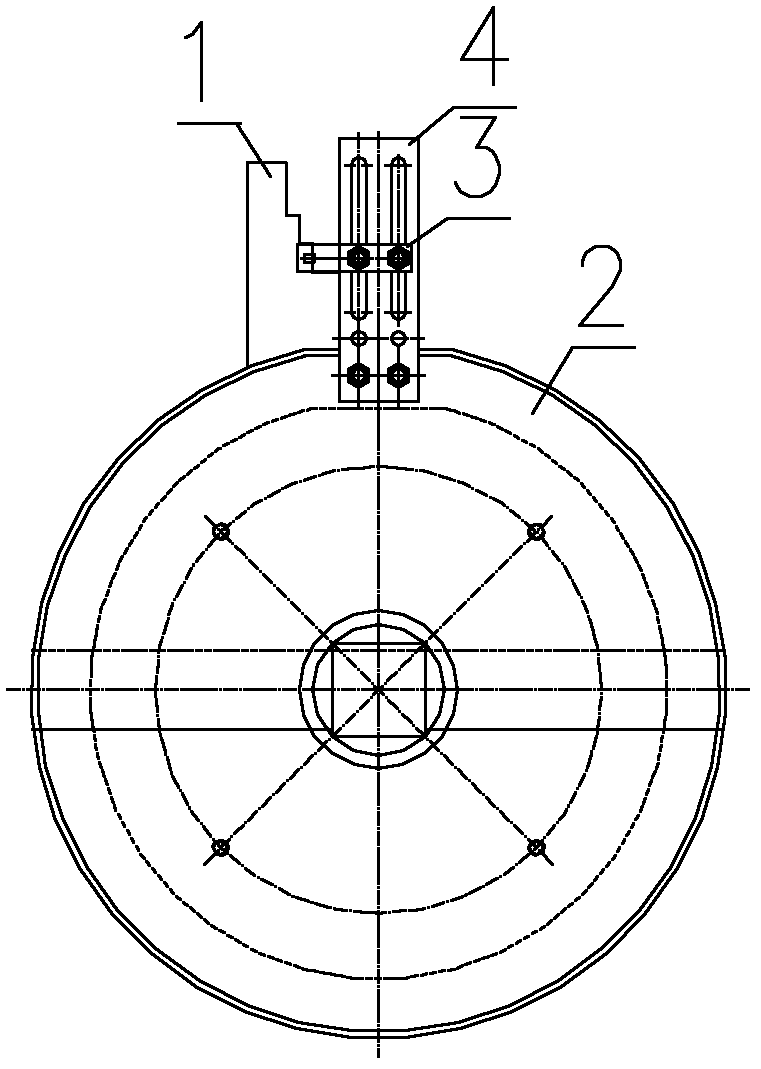

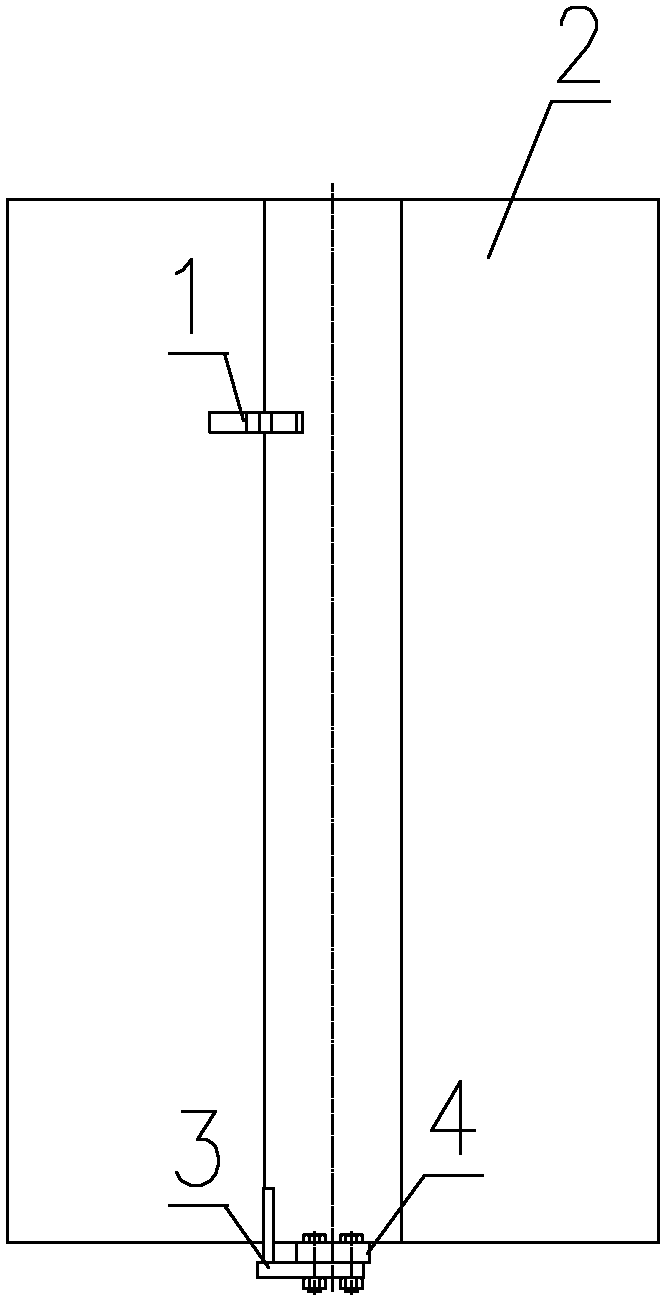

[0024] A foil wound coil die for multiple copper discharge wires including end plates, support plates and die roll. The upper end of the steel plate rolling cylinder 2 for the mold foil winding coil is fixed with a copper bar upper end outlet baffle plate 1; the lower end has a hole, and an outlet fixing plate 4 is fixed. Fixing block 3 for the outgoing line at the lower end of the row.

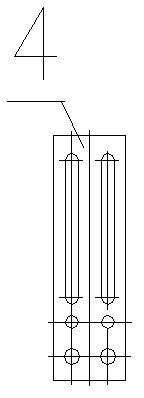

[0025] The slot holes of the lower end of the steel plate rolling drum for the outlet fixing plate are 2 elongated through holes. The outgoing wire fixing block at the lower end of the copper bar is an L-shaped structure, and is fixed on the outgoing wire fixing block by bolts. The outlet baffle plate at the upper end of the copper bar is welded on the steel drum.

[0026] The winding process of this embodiment:

[0027] Refer to attached Figure 1 to Figure 5 .

[0028] During winding, the mold is installed on the threading bar of the foil winding machine, the outlet baffle plate 1 at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com