Fertilizing, spraying, ridging and full-filming machine for potato

A potato and film-laying machine technology, applied in the field of agricultural machinery, can solve the problems of loose connection between films, low efficiency, uneven ridge shape, etc., and achieves the effects of reasonable structure, easy use and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

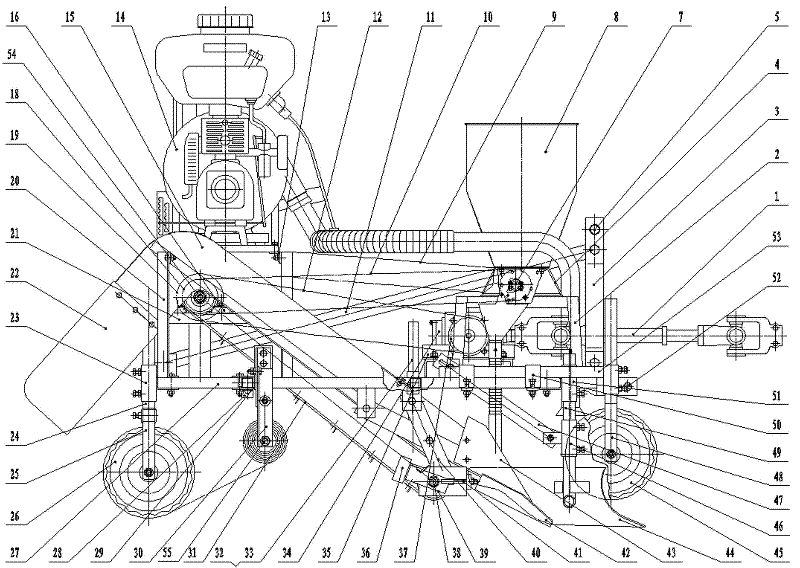

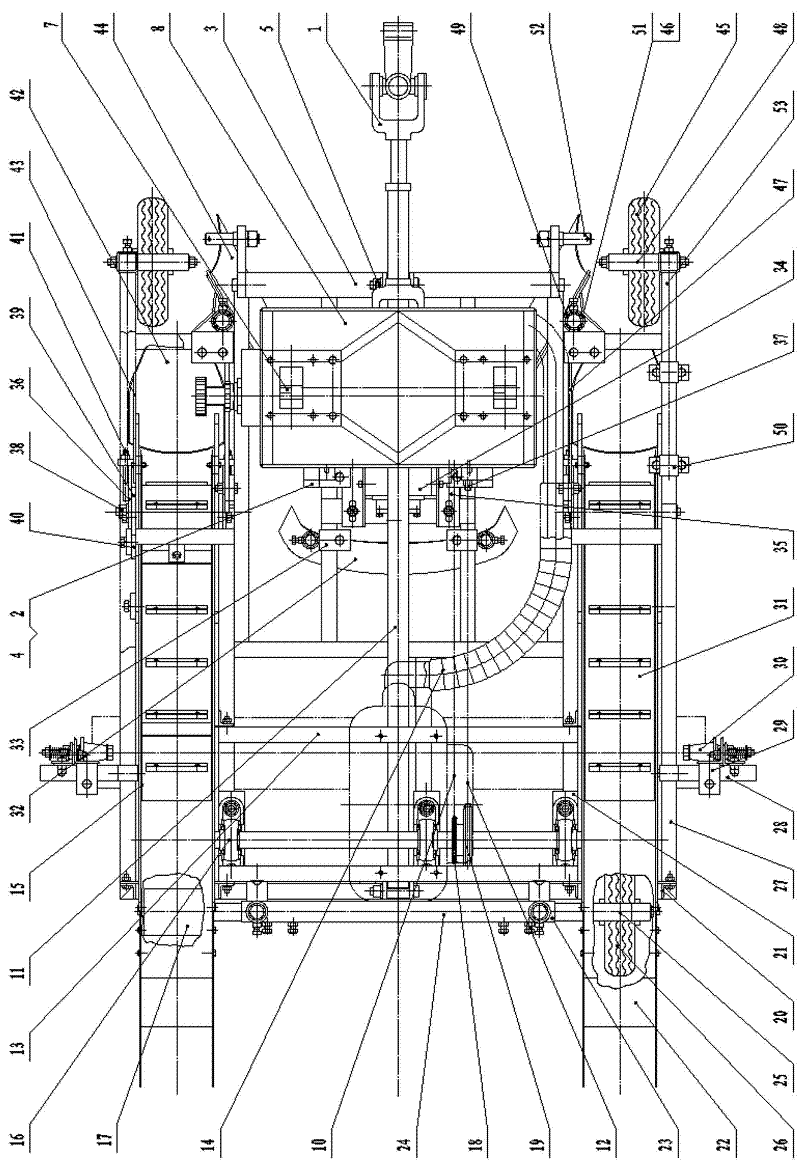

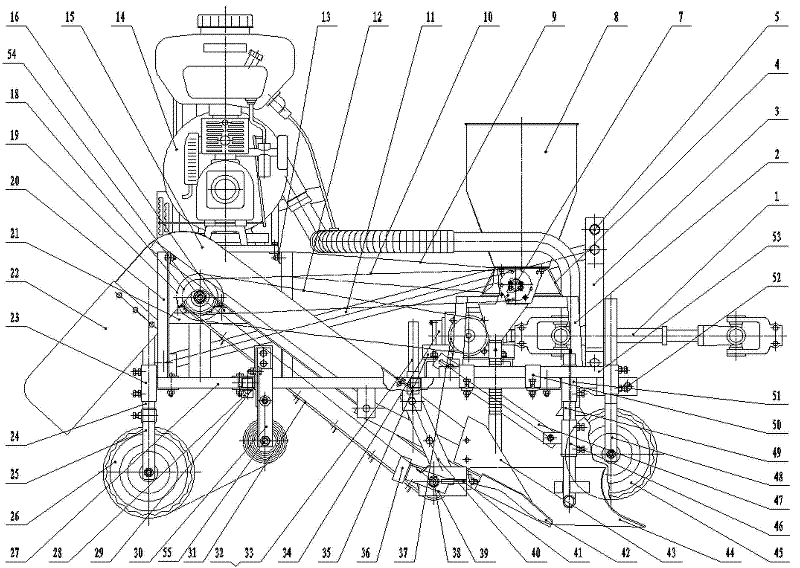

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Referring to Figure 1, refer to figure 2 , a potato fertilization, spraying, ridge and film-laying machine for supporting operations with a four-wheel tractor, including a frame 27, a triangular traction frame 3, a transmission 34, a fertilization assembly, a spraying assembly, a ridge plow 44, a film-laying assembly, On the soil conveying device, the two ends of the forearm of the frame 27 are provided with a lower traction pin 52, and the upper center of the front part of the frame 27 is provided with an adjustable lower bracket 2 for fertilization, and the rear of the lower bracket 2 is sequentially provided with the transmission. Adjustable bracket 35 and adjustable ridge top shaper bracket 33; fertilization assembly is installed on the adjustable lower bracket 2 of the fertilization assembly, and a transmission 34 is installed on the adjustable transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com