High-frequency auxiliary power supply device for gas shield welding

A high-frequency auxiliary and power supply device technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as unfavorable operation, large volume and weight, and achieve miniaturization, improved work reliability, and reduced heat generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

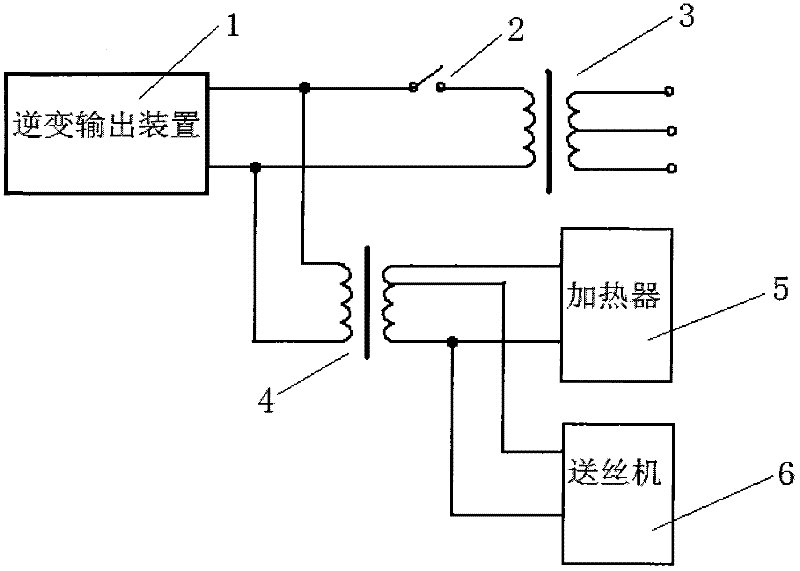

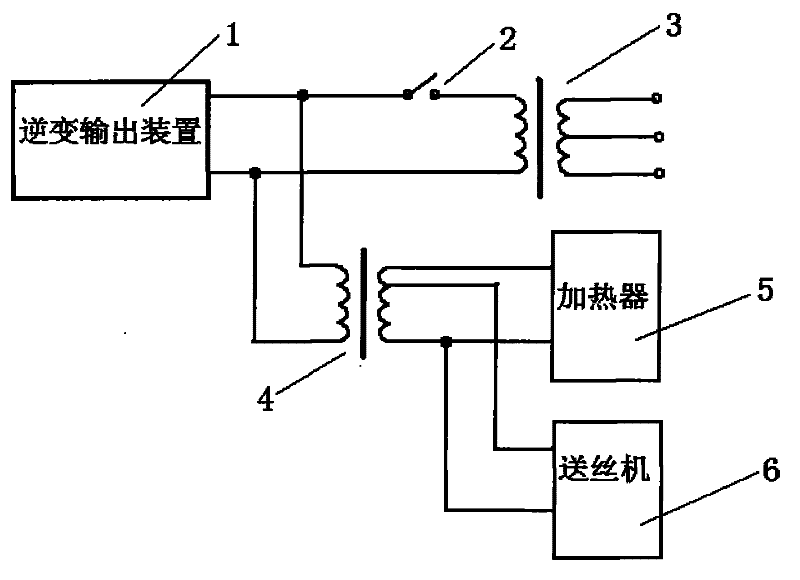

[0008] see figure 1 As shown, the high-frequency auxiliary power supply device for gas shielded welding is mainly composed of an inverter output device 1, a high-frequency transformer 4, a heater 5, and a wire feeder 6. One end of the high-frequency transformer 4 is connected to the inverter output device 1. The other end is connected with the heater 5 and the wire feeder 6 , and its inverter output device 1 is also connected with a welding transformer 3 at the same time, and a relay 2 is arranged between the inverter output device 1 and the welding transformer 3 .

[0009] When welding is not welding, the relay 2 is disconnected, the welding transformer 3 does not work, and the voltage of the inverter output device 1 is applied to the high-frequency transformer 4 to generate 36V high-frequency heating voltage, which is supplied to the heater 5.

[0010] When welding, the relay 2 pulls in, and the inverter output device simultaneously supplies the welding transformer 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com